One-step frequency modulation control method for steam turbine

A control method and technology for steam turbines, applied in mechanical equipment, engine components, engine starting, etc., can solve problems such as unit control and safety impact, unfavorable power grid stability, and weakened capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

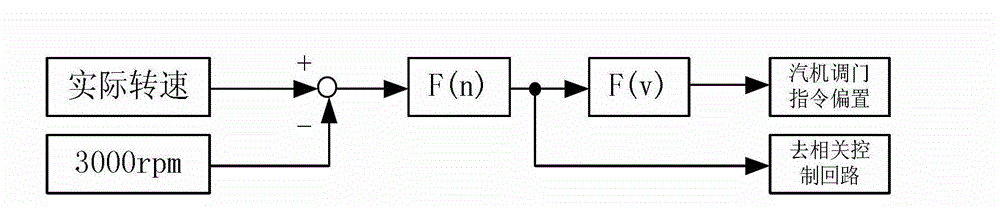

[0020] Specific implementation mode one: the steam turbine primary frequency modulation control method of the present implementation mode is realized according to the following steps:

[0021] Step 1: The adjustment system calculates and monitors the speed deviation in real time:

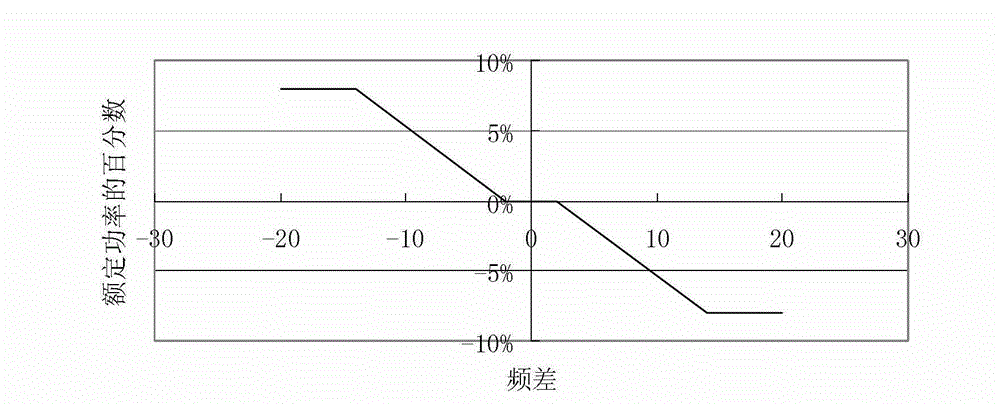

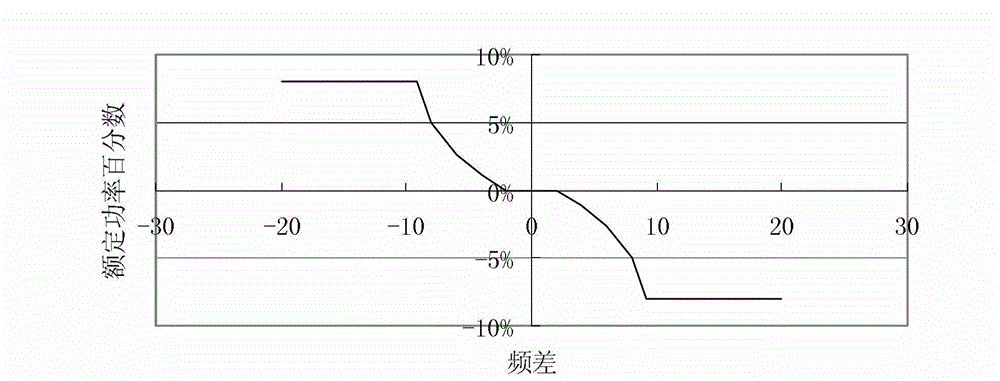

[0022] In the case that the speed variation is variable at 3% to 6%, set the frequency modulation deviation dead zone as ±2r / min, and the frequency modulation range as ±8%; wherein, the speed variation is variable at 3% to 6%. The changing situation is: when 2≤Δn<4rpms, the speed variation rate is 6%, when 4<Δn≤6rpms, the speed variation rate is 5%, when 6<Δn≤8rpms, the speed variation rate is 4%, 8<Δn When ≤9.2rpms, the speed variation rate is 3%;

[0023] Step 2: Carry out primary frequency modulation control according to the set speed variation rate, that is, the steam turbine primary frequency modulation control method is completed.

[0024] In this embodiment, Δn is the rotational speed devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com