Method for blocking high stress in upper part of ore body by using pressure relief groove

A pressure-relief groove and high-stress technology, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of large damage to the surrounding rock of the hanging wall, collapse of the stope roof, and roof fall, and achieve the effect of accurate and reliable pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings and specific embodiments.

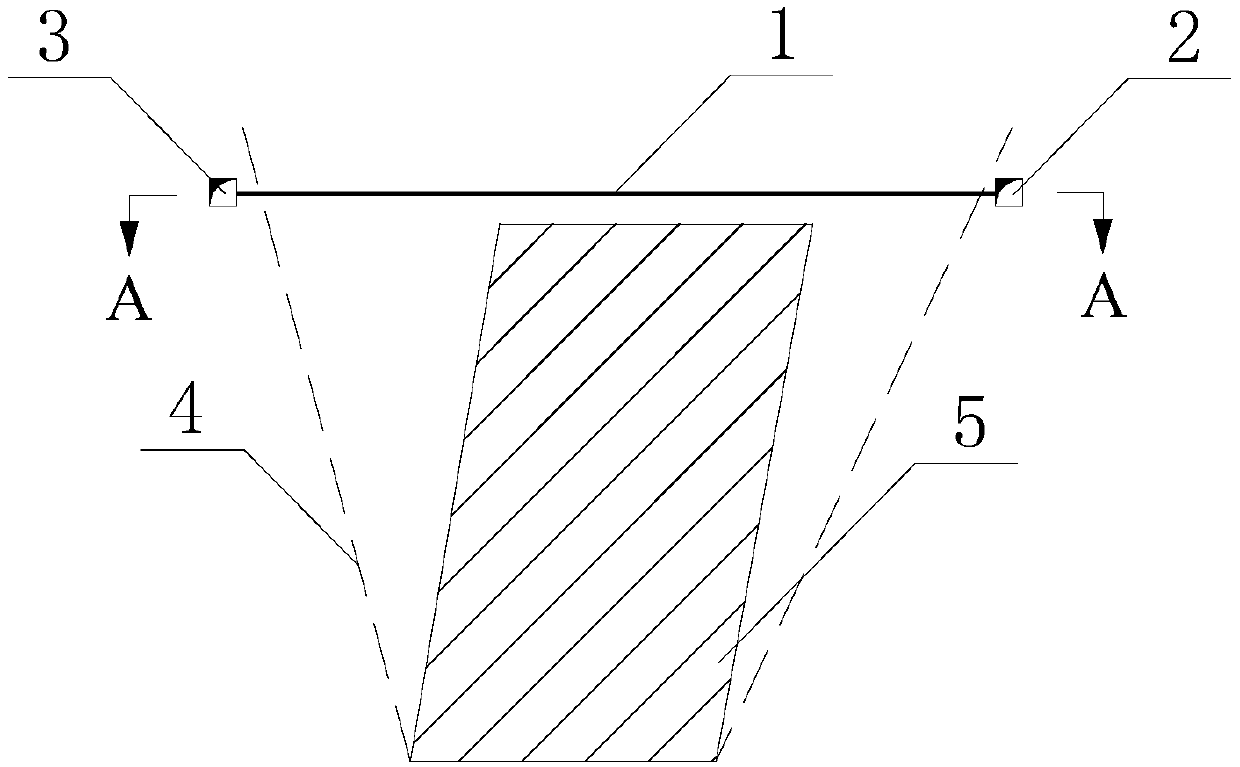

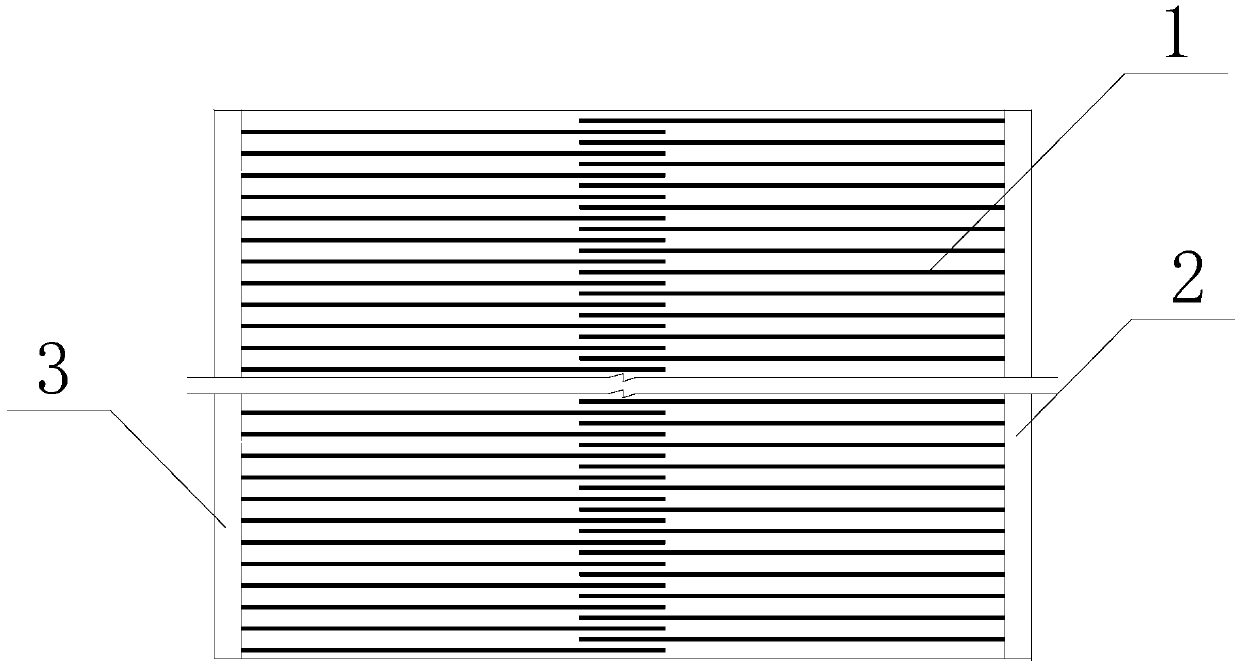

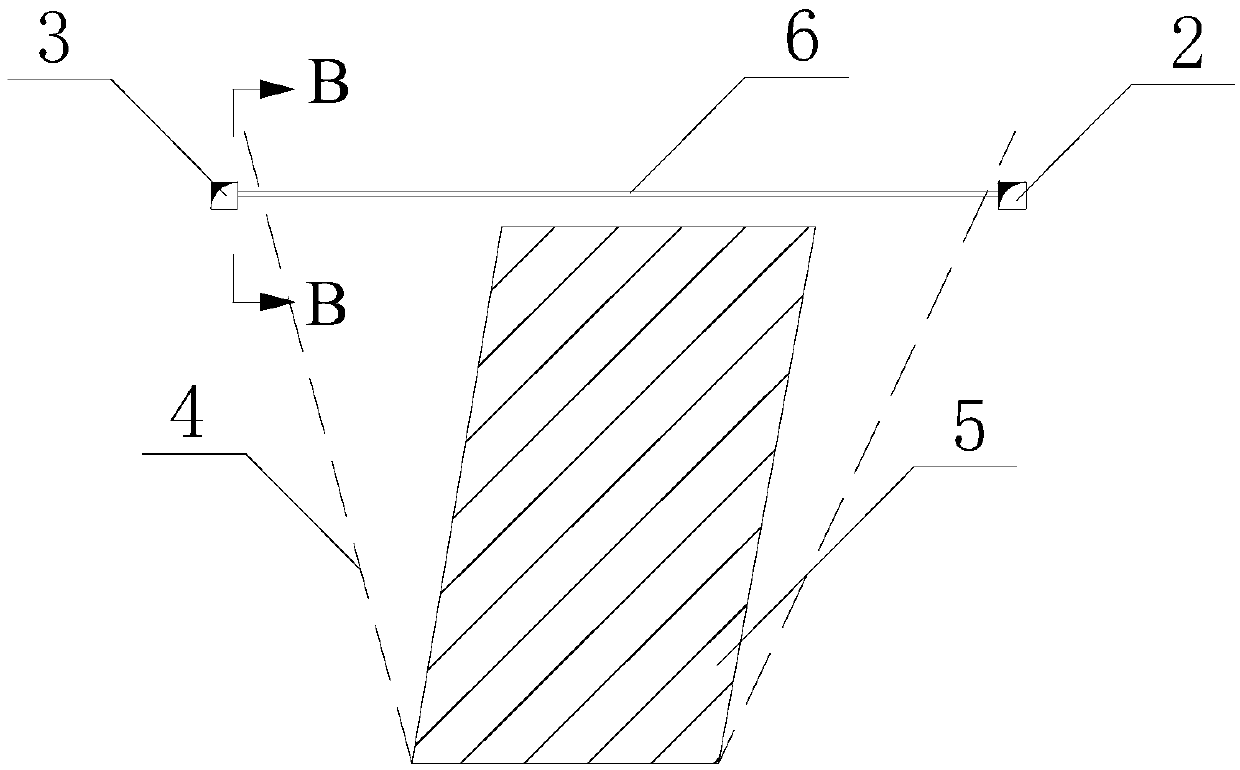

[0023] See Figure 1-4 , The method of the present invention to block the high stress on the upper part of the ore body by using the pressure relief groove includes the steps:

[0024] (1) Prejudge the moving boundaries of the upper and lower rock layers formed after the mining of 1 to 3 middle ore bodies 5 according to the specific conditions of the site to determine the pressure relief boundary 4.

[0025] (2) On the outer side of the pressure relief boundary 4 on the top side of the upper and lower walls of the ore body 5, the lower wall rock drilling roadway 2 and the hanging wall rock drilling roadway 3 are respectively arranged along the strike, and the upper and lower wall rock drilling roadways meet the requirements of rock drilling and blasting operations. It is required that the two are located on the same horizontal line, and the cross-sectional size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com