Method and device for high-tension switch cabinet gas detection

A high-voltage switchgear, gas detection technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to accurately measure operating temperature, insufficient accuracy, and inability to obtain test components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

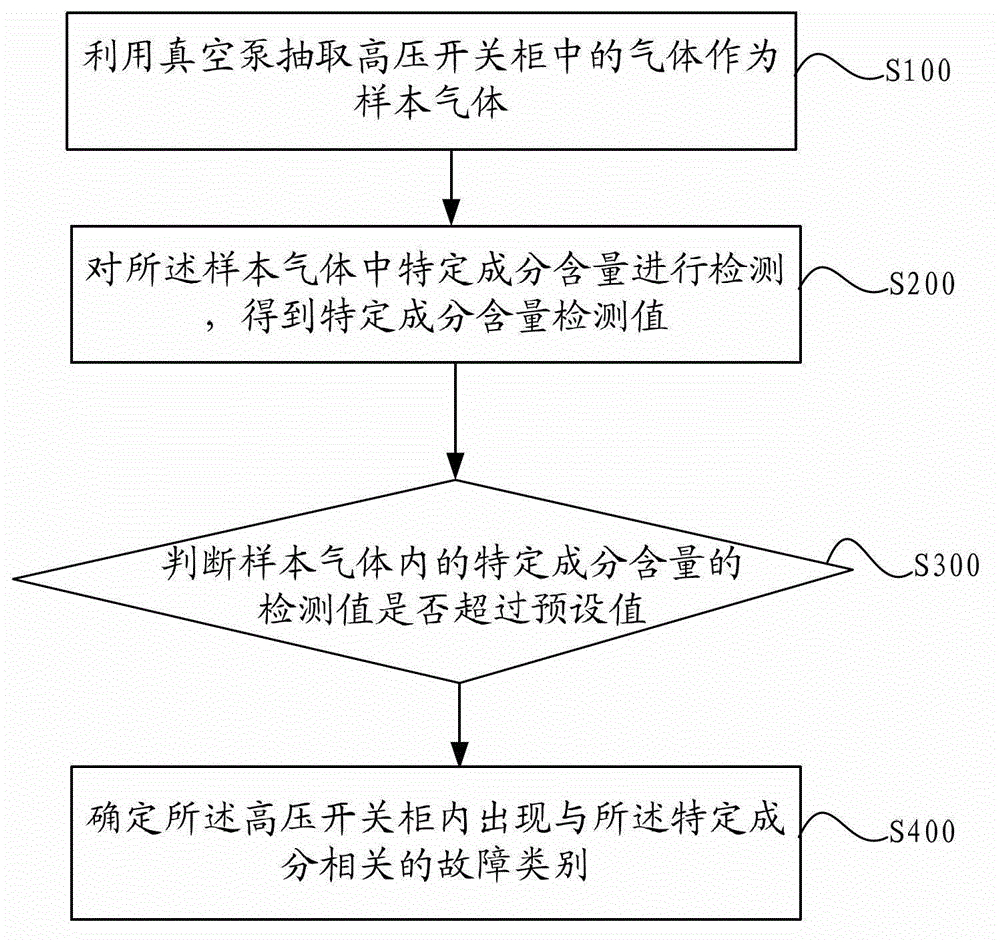

[0054] figure 1 It is a schematic flowchart of the method for detecting gas in a high-voltage switchgear provided in the embodiment of the present application.

[0055] Such as figure 1 As shown, the method includes:

[0056] S100: Using a vacuum pump to extract gas in the high-voltage switchgear as a sample gas.

[0057] When there is a fault in the high-voltage switchgear, the fault here includes: contact overheating, partial discharge, SF6 leakage, etc., the gas composition in the high-voltage switchgear will change, for example: after partial discharge, it will cause ozone in the gas The amount increases; and when the contacts are overheated, the concentration of particulate matter in the air will increase.

[0058] Therefore, analyzing the gas in the high-voltage switchgear can be used as a means of fault detection.

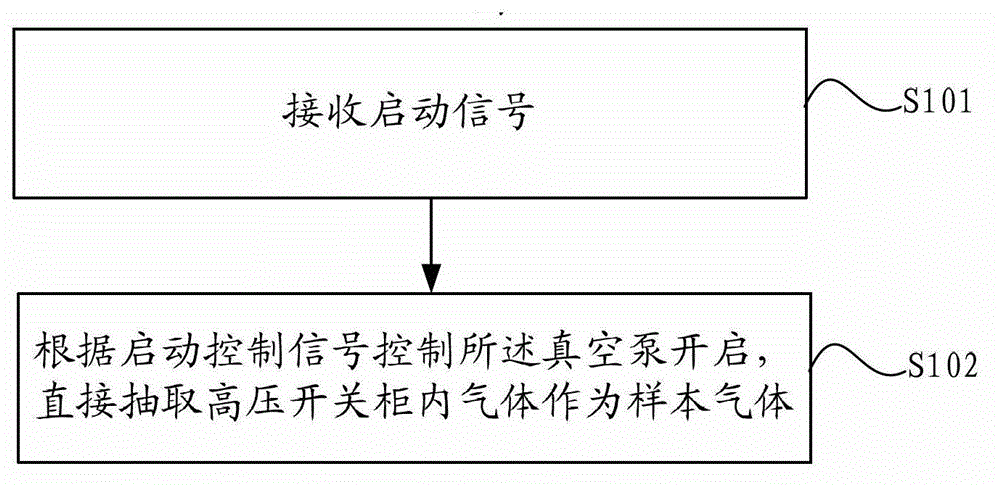

[0059] In addition, in the embodiment of the present application, when the vacuum pump is located inside the high-voltage switchgear, such as figure 2...

Embodiment 2

[0085] Figure 5 It is a schematic structural diagram of a gas detection device for a high-voltage switchgear provided in an embodiment of the present application.

[0086] Such as Figure 5 As shown, A in the figure is a high-voltage switchgear, and the gas detection device includes: a gas acquisition unit 10, a gas channel 20, a gas sensor 30, a judgment unit 40 and a fault category determination unit 50, wherein:

[0087] The gas acquisition unit 10 communicates with the space in the high-voltage switchgear, and is used to extract the gas in the high-voltage switchgear as a sample gas, and deliver the sample gas into the gas channel 20 .

[0088] In the embodiment of this application, as Figure 5 As shown, the gas acquisition unit 10 may include: a signal receiving unit 11, a vacuum pump 12 and an exhaust pipeline 13, wherein:

[0089] A signal receiving unit 11, configured to receive a start control signal, and send the start control signal to the vacuum pump;

[0090...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com