Sliding mode control method for methanol auto-thermal reforming hydrogen generation process

A self-thermal reforming and control method technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as difficult control, difficulty in achieving good control effect with classical control algorithms, shortening the life of fuel cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

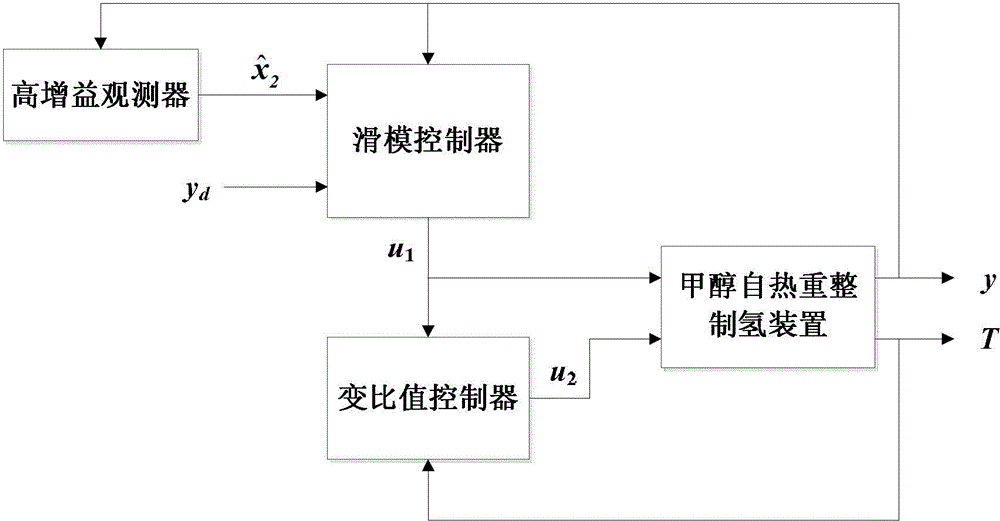

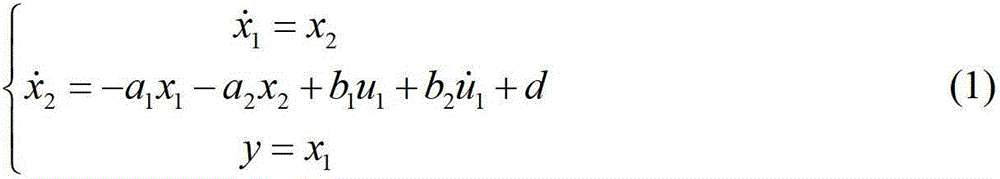

[0035] Sliding mode control method of methanol autothermal reforming hydrogen production process to respond to the flow u of methanol aqueous solution 1 and the flow rate u of another reaction raw material air 2 As the manipulated variables, the hydrogen output y and the reforming temperature T are the controlled variables.

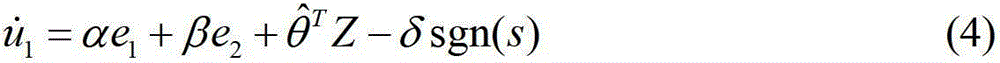

[0036] A sliding mode control method for the hydrogen production process of methanol autothermal reforming, which is characterized in that the sliding mode controller is used according to the expected hydrogen production y d , the actual hydrogen production y and the change rate of the actual hydrogen production x 2 To manipulate the flow rate u of the methanol aqueous solution of the reaction raw material 1 , while using a variable ratio controller with a constraint on the reforming temperature T to manipulate the flow rate u of the other reaction raw material air 2 , the specific steps include:

[0037] In the methanol aqueous solution, the molar ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com