Multifunctional socket structure

A multi-functional socket and oblique insertion technology, applied in the base/shell, contact parts, electrical components, etc., can solve the problem of lack of universality of two-hole and three-hole sockets, and achieve the advantages of popularization and implementation, simple process and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

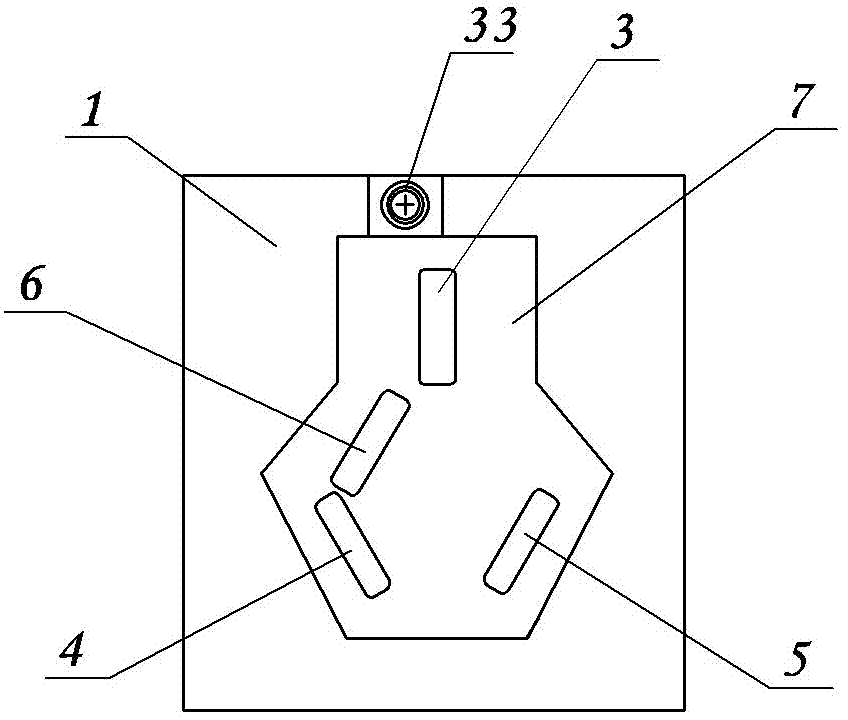

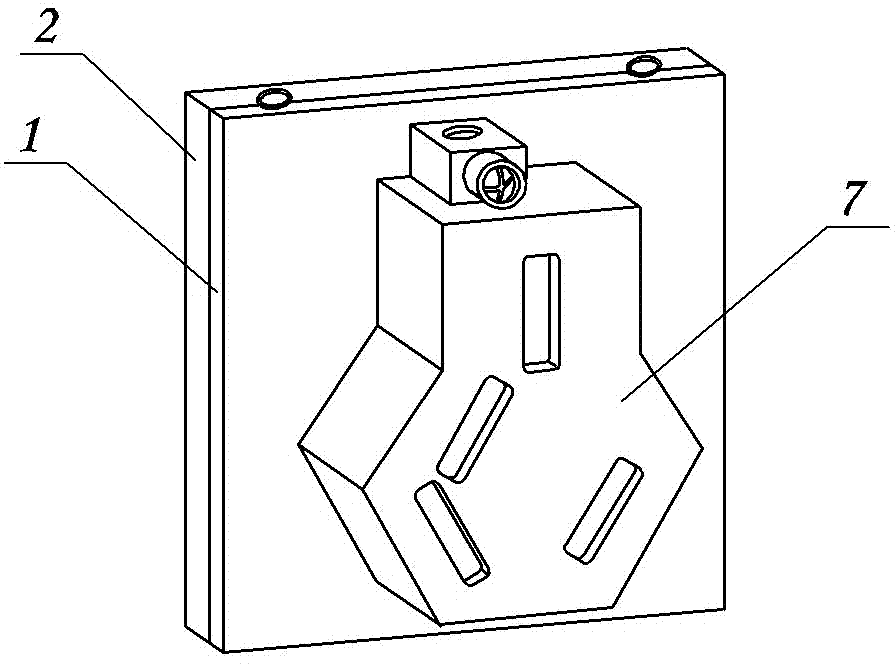

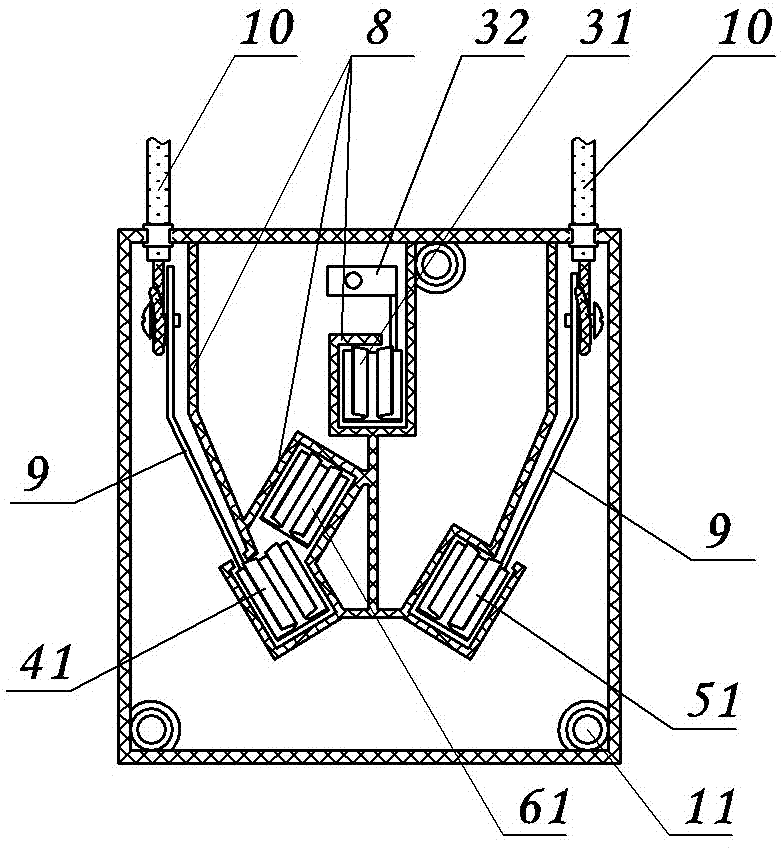

[0027] Embodiment 1: a kind of multifunctional socket, see figure 1 and figure 2 , the base 2 and the panel 1 are interlocked and fixed together, and the panel is provided with three jacks matching the three-hole plug, which are the ground wire jack 3, the left oblique jack 4 and the right oblique jack 5. see image 3 and Figure 4 , the base 2 is respectively provided with a ground wire insertion piece 31 corresponding to the three sockets, a left oblique insertion piece 41 and a right oblique insertion piece 51 . In the area between the upper side of the left oblique jack 4 and the ground wire jack 3, a fourth jack 6 parallel to the right oblique jack 5 is provided, and the fourth jack 6 can cooperate with the right oblique jack 5. The two-hole plug is used together, and the base 2 is provided with a fourth insertion piece 61 corresponding to the fourth jack 6 , and the fourth insertion piece 61 is electrically connected to the left oblique insertion piece 41 .

[0028...

Embodiment 2

[0029] Embodiment 2: A multifunctional socket structure, the structure of the panel 1 can be found in Figure 9 , see the structure of base 2 Figure 10 . On the panel 1, there are three jacks matched with the common three-hole plug, which are respectively the ground wire jack 3, the left oblique jack 4 and the right oblique jack 5, and the base 2 is respectively provided with three jacks. The ground wire insertion piece 31 , the left oblique insertion piece 41 and the right oblique insertion piece 51 correspond to the hole.

[0030] And, in the area between the upper side of the left oblique insertion hole 3 and the ground wire insertion hole 4, a fourth insertion hole 6 parallel to the right oblique insertion hole 5 is provided, and the fourth insertion hole 6 is connected to the right oblique insertion hole 5. Cooperate to form a two-hole socket, which can be matched with a general two-hole plug.

[0031] Moreover, a fourth insertion piece 61 corresponding to the fourt...

Embodiment 3

[0033] Embodiment 3: The drawings are not drawn, and the content is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that a structure with five jacks is provided. On the basis of Embodiment 1, in the area between the upper side of the right oblique jack and the ground wire jack, a fifth jack parallel to the left oblique jack is provided, and the fifth jack is connected to the left oblique jack. Cooperate to form a two-hole socket, which can be matched with a general two-hole plug.

[0034] Therefore, this embodiment realizes the overlapping of two two-hole sockets and one three-hole socket, satisfying three functional usage modes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com