Liquid-cooled motor

A technology of liquid-cooled motors and motor housings, which is applied in the direction of electrical components, electromechanical devices, and electric components, and can solve the problems of large loss, poor cooling effect of internally cooled motors, and high cost, and achieve lower thermal resistance and reduced Mechanical loss, reducing the effect of thermal resistance chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

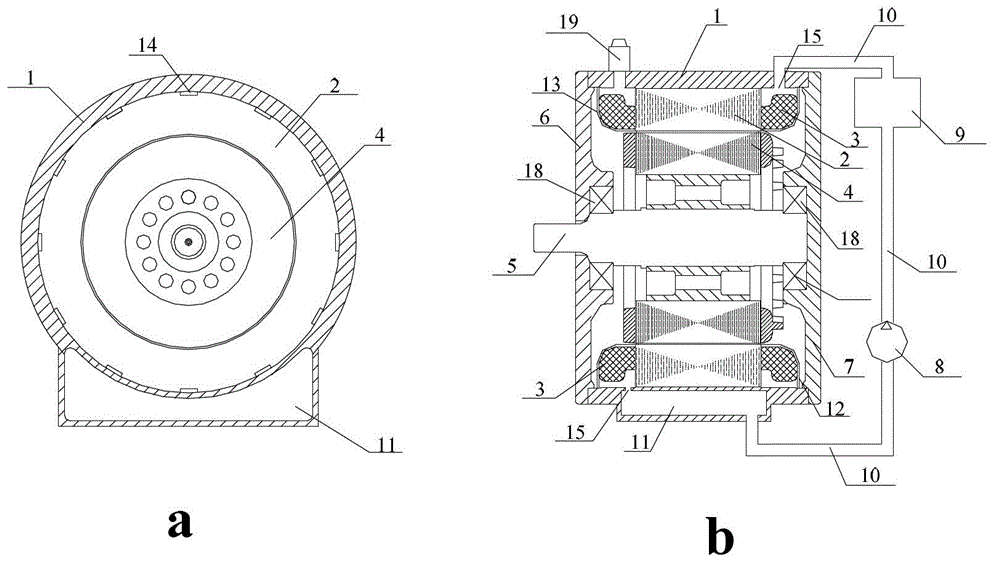

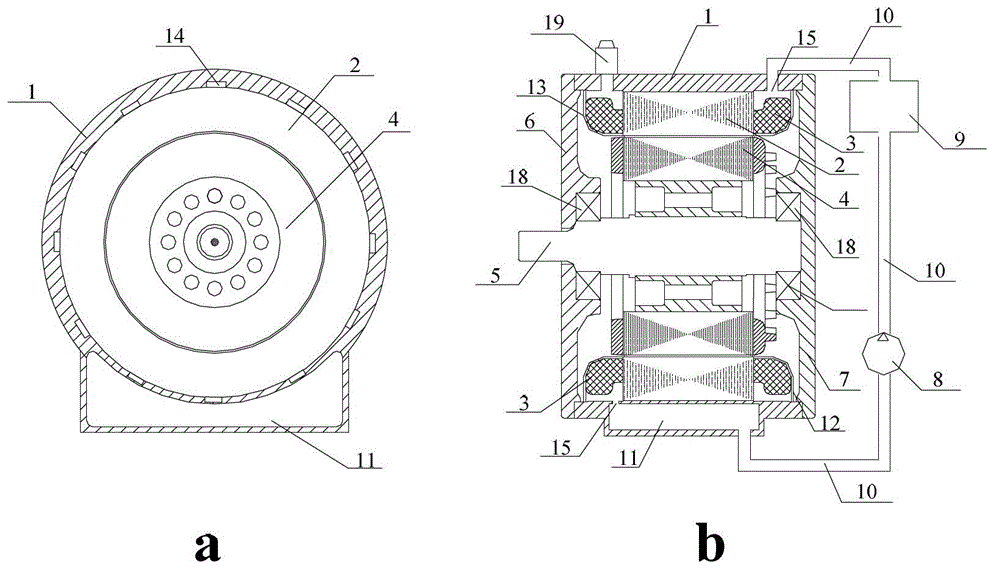

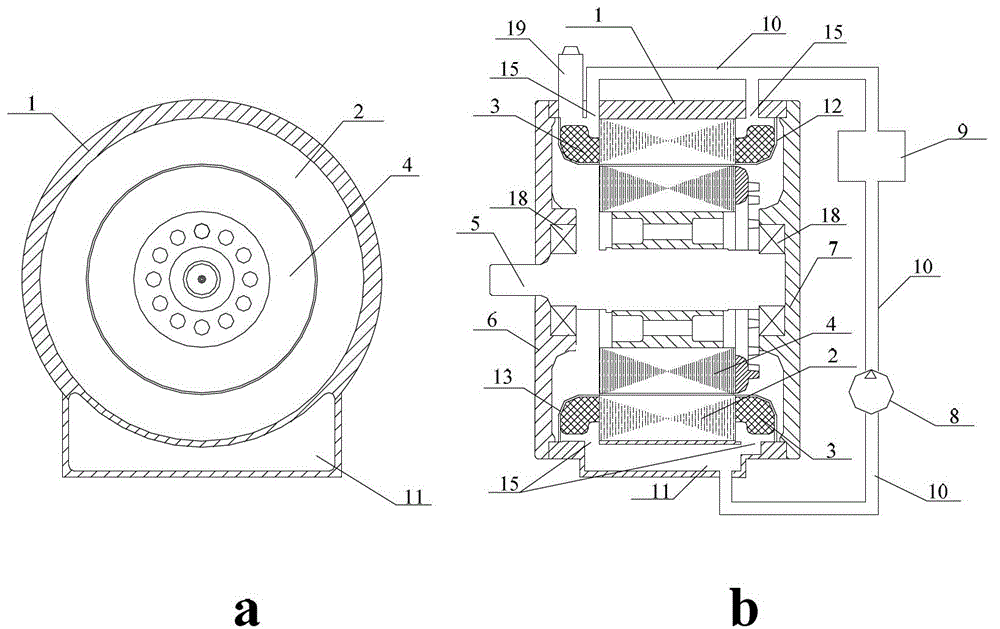

Image

Examples

Embodiment 5

[0037] In Example 5, the second sealing cover (13) has an overflow hole (17) and the corresponding return hole, but the first sealing cover (12) does not have it. In fact, the first sealing cover (12) has an overflow hole (16) Or the second seal cover (13) has an overflow hole (16) or both seal covers have overflow holes (16), and the overflow hole (16) is located on the upper part of the seal cover where it is located and the bearing on its side ( 18) above, the lower part of the motor housing (1) has a return hole (17), the return hole (17) is located under the bearing (18) on the side where it is located, and the return hole (17) communicates with the liquid storage tank (11) . If the first sealing cover (12) or the second sealing cover (13) has an overflow hole (16), the bearing (18) on the side thereof is an open bearing. When the liquid level rises to the height of the overflow hole (16), the coolant (cooling oil at this time) overflows through the overflow hole (16), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com