Illuminator packaging structural capable of preventing electrostatic damaged and manufacturing method therefor

A technology of packaging structure and electrostatic destruction, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of low thermal resistance of metal materials, hindering the output beam, thickness limitation, etc., and achieve the effect of low thermal resistance and excellent heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The technical means and functions used to achieve the purpose of the present invention will be described below with reference to the accompanying drawings, and the embodiments listed below with the accompanying drawings are only for auxiliary illustration, and the technical means of this case are not limited thereto.

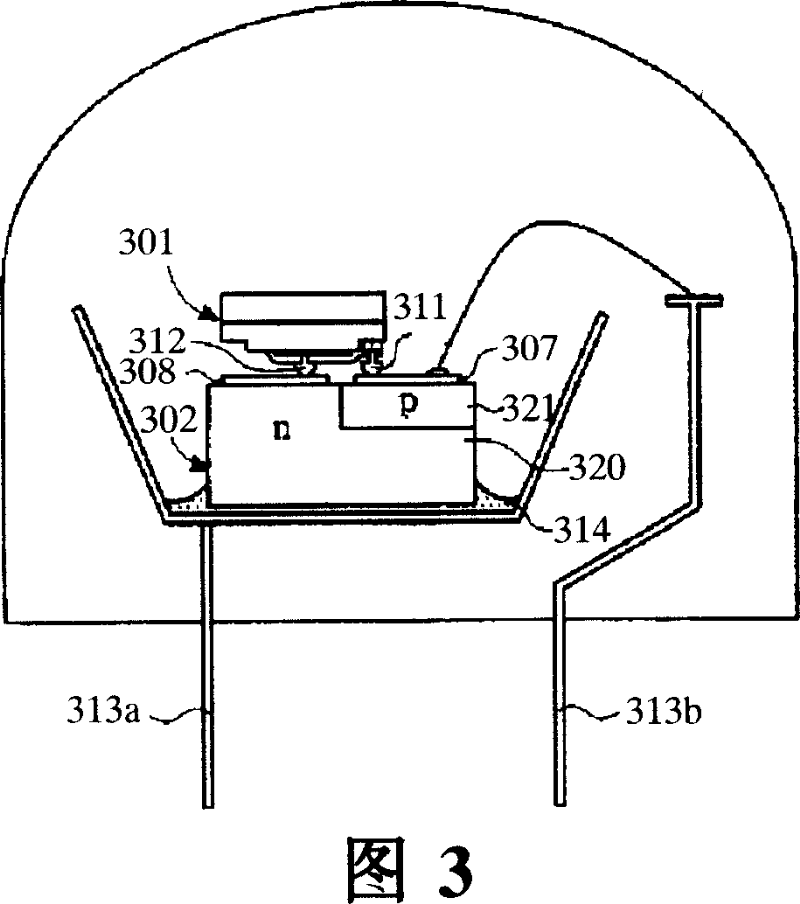

[0079] First please refer to a preferred embodiment of the present invention shown in FIG. 6, the light emitter packaging structure 10 that can prevent electrostatic damage, which is mainly composed of a light emitting diode 2, two carrying bases 3, 4, and an electrostatic protection component 5. .

[0080] The light-emitting diode 2 is a chip-type light-emitting diode with a P-type electrode 21 and an N-type electrode 22 , and is disposed on the two carrying bases 3 , 4 . It must be noted that the light emitting diode 2 can be any other solid-state light source capable of emitting light energy, and is not limited to light emitting diodes.

[0081] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com