Processing technology of high-thermal-conductivity aluminum substrate

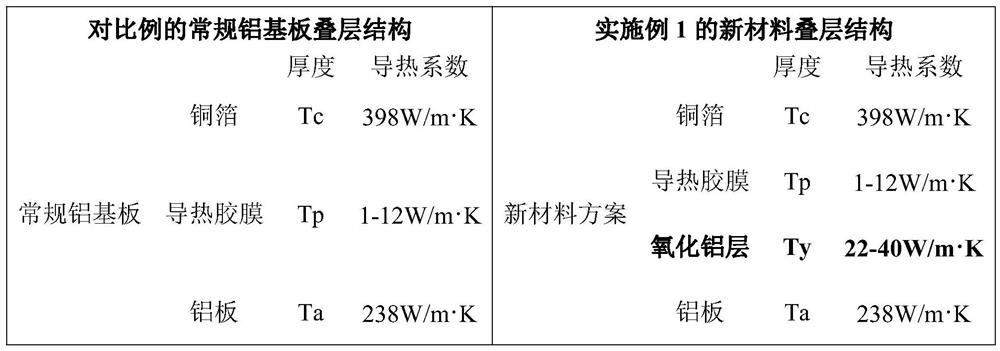

A processing technology and technology of aluminum substrates, applied in circuit substrate materials, circuit thermal devices, electrical components, etc., can solve the problems of inability to meet the heat dissipation requirements of electronic products, thin anode thickness of aluminum substrates, and poor thermal conductivity, etc., to increase the thickness. , The breakdown voltage is stable, the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A processing technology for a high thermal conductivity aluminum substrate, specifically comprising the following steps:

[0029] S1. Choose 1060 series aluminum plate, the thickness of the aluminum plate is 0.5-3.0 mm;

[0030] S2. Anodize the 1060 aluminum plate, the thickness of the anode is 30-120 microns; the oxidation time is 2-20 hours, the voltage is controlled at 14V-22V, and the current is controlled at 3500-4200A;

[0031] S3. Take the pressed steel plate mold and place the steel plate lower mold;

[0032] S4. Tiling the bottom copper foil;

[0033] S5. Place the heat-conducting adhesive film for insulation and heat dissipation flatly, and the thickness of the adhesive film is 25-200 mm;

[0034] S6. Place the thick anode of the aluminum plate downwards, and the anode film is in contact with the heat-conducting adhesive film;

[0035] S7. Place the upper mold of the steel plate, fasten the upper and lower steel plates and push them into the press, and pres...

Embodiment 2

[0051] A process for processing high thermal conductivity aluminum substrates. Compared with Example 1, the anode thickness of the aluminum plate is 20-150 microns; the oxidation time is 5-20 hours, the voltage is controlled at 14V-22V, and the current is controlled at 3500-4200A; other processes Process is the same as embodiment 1.

Embodiment 3

[0053] A processing technology for a high heat-conducting aluminum substrate, compared with Embodiment 1, the thickness of the heat-conducting adhesive film is 50-100 mm; other processes are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com