Apparatus for controlling the temperature of a freezable operating/auxiliary medium

A technology of auxiliary materials and equipment, applied in mechanical equipment, machines/engines, exhaust gas treatment, etc., can solve the problems of delayed de-freezing performance and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

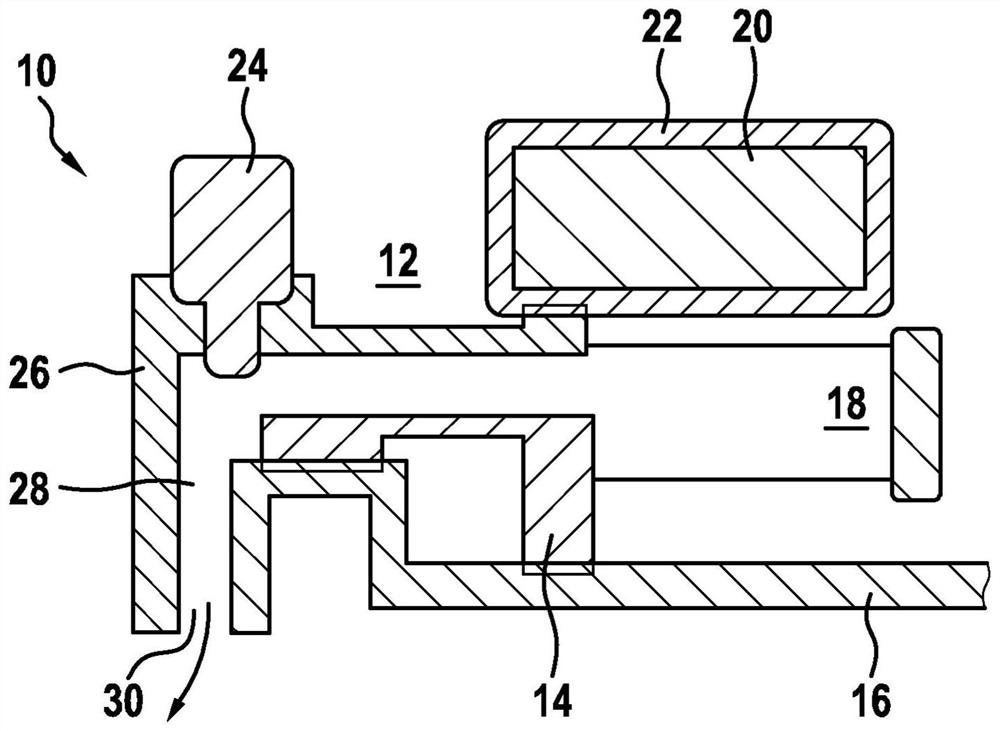

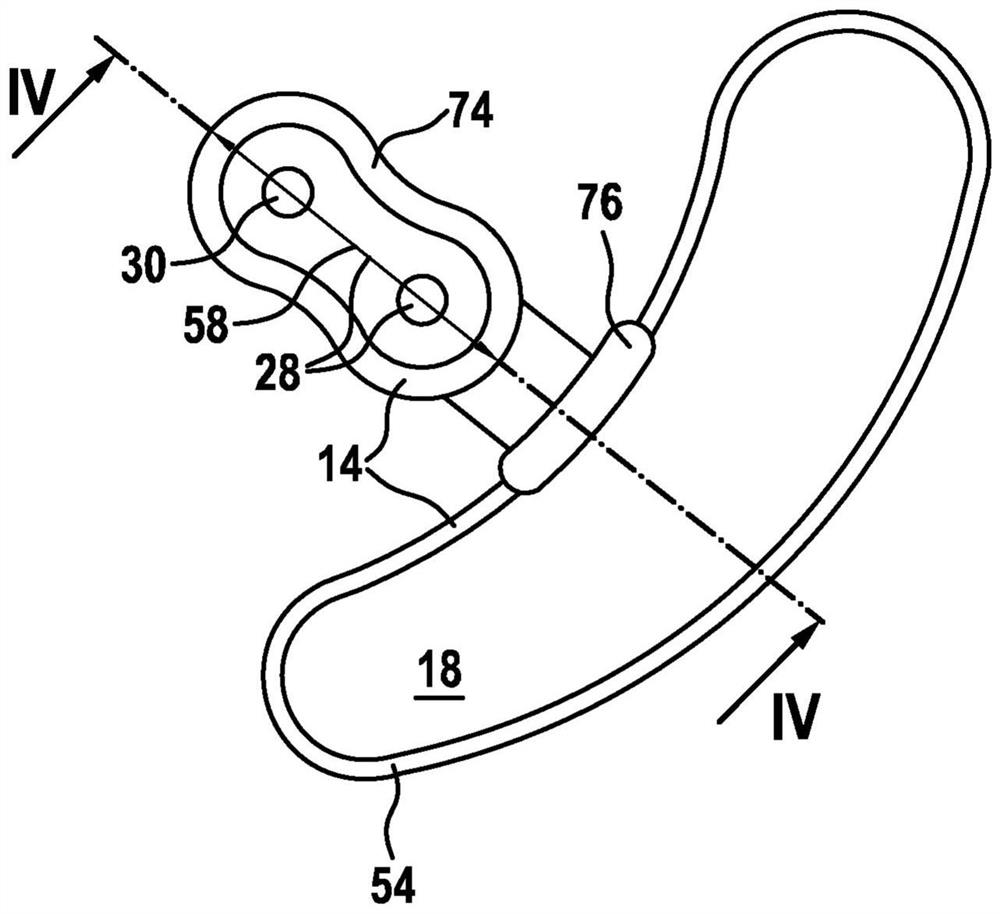

[0025] from according to figure 1 The illustration in FIG. 2 shows a storage tank 10 in which a freezeable operating / auxiliary material 12 , preferably a reducing agent, is received. Freezable operating / auxiliary materials freeze at temperatures below -11°C. Such as figure 1 As shown, a filter 14 is connected upstream of the suction channel 28 . A filter 14 may be received on a carrier 16 and include a filter web 18 . Located above the filter 14 is a heating / cooling body 20 which is surrounded by an injection-molded encapsulation 22 which usually consists of a plastic material. Furthermore, heat conducting pins 24 , for example made of stainless steel, are located in the filter cover 26 . The delivery device inlet 30 extends from the suction channel 28 to the figure 1 Delivery device not shown.

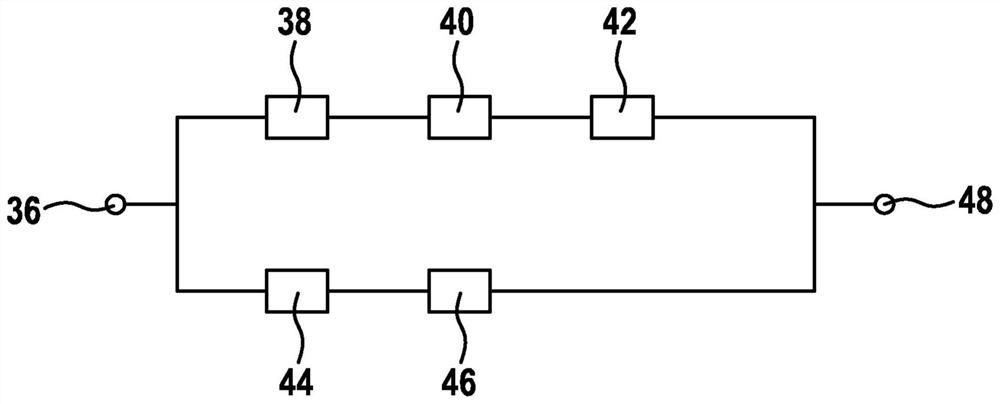

[0026] in accordance with figure 1 appears in the solution of figure 2 The thermal resistance shown in. if based on figure 2 The schematic diagram shows that at T 加热器 ,36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com