Viscous clutch valve assembly

A clutch and valve assembly technology, applied in clutches, friction clutches, fluid clutches, etc., can solve problems such as problems, large electromagnetic coils, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention generally relates to a valve assembly suitable for use with a viscous clutch. For example, the valve assembly of the present invention is suitable for use with PCT Application No. PCT / US2010 / 056659, filed November 15, 2010, and U.S. Provisional Patent Application No. 61, entitled "Integrated viscous clutch," filed November 17, 2009. / 261,965, each of which is hereby incorporated by reference in its entirety. This application claims priority to US Provisional Patent Application No. 61 / 375,173, filed August 19, 2010, entitled "viscous clutch valve assembly," which is hereby incorporated by reference in its entirety.

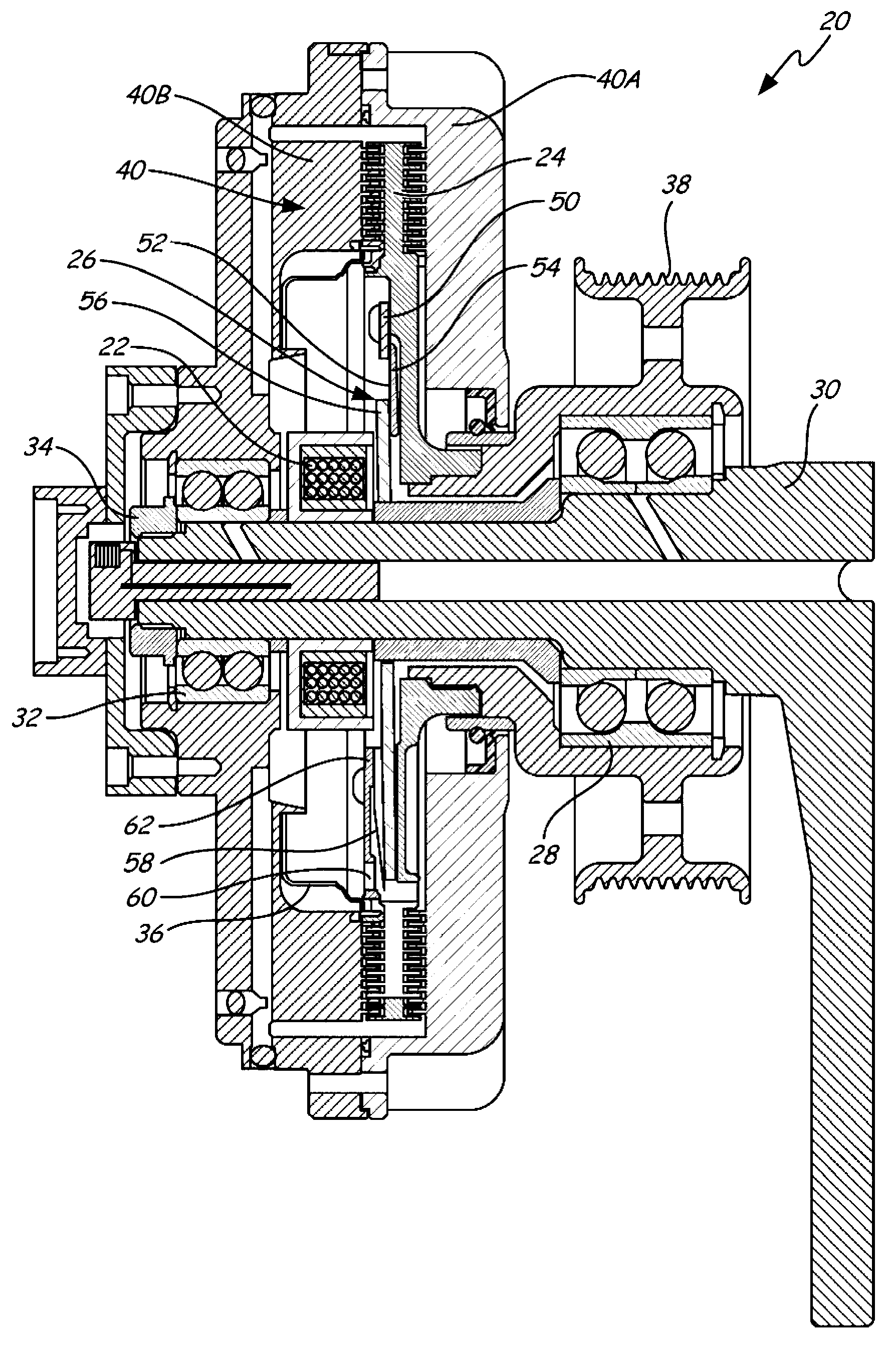

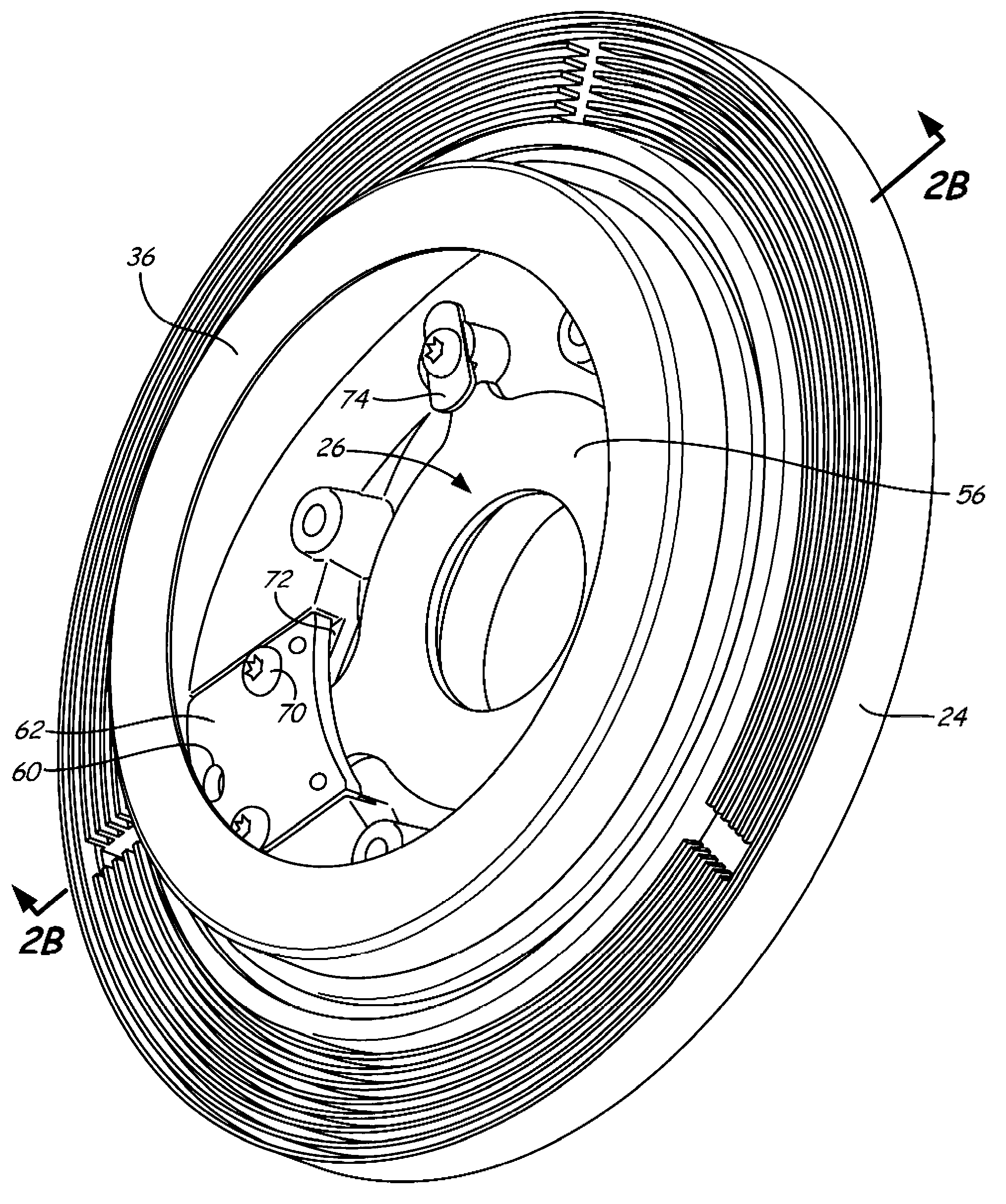

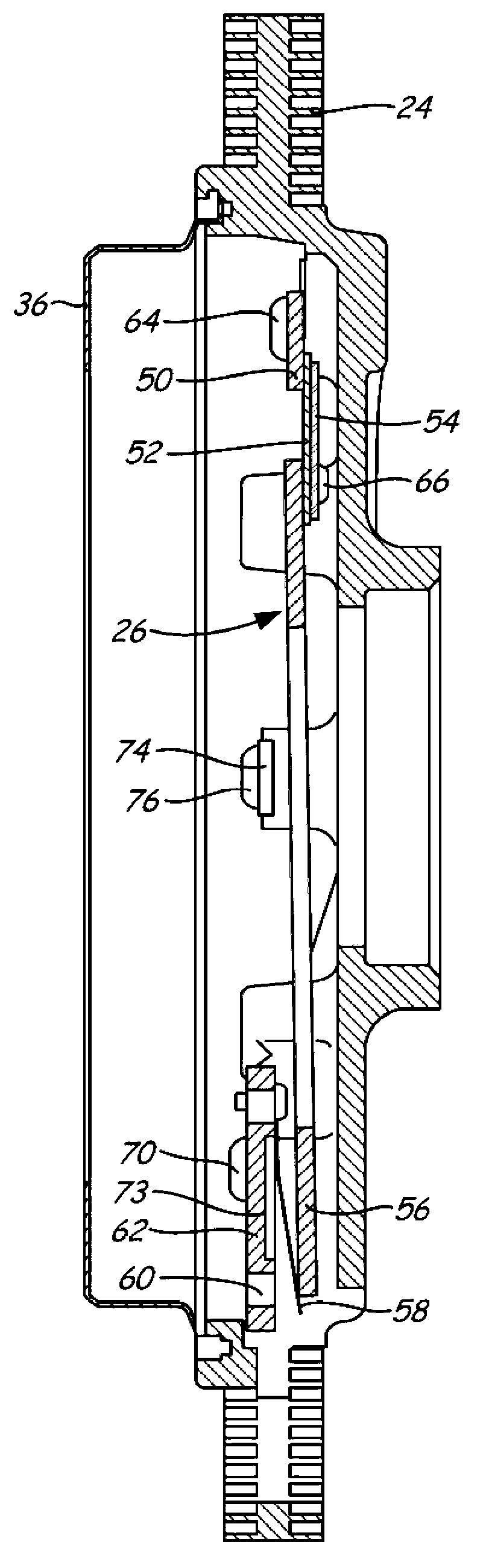

[0015] figure 1 is a cross-sectional view of one embodiment of a viscous clutch 20 comprising a solenoid assembly 22, a rotor 24, a valve assembly 26, a first support device 28, a shaft (or bracket) 30, a second support device 32, a retaining A member 34 , a reservoir 36 , an input member 38 (eg, a sheave), and an output member 40 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com