Flexible ultrasonic phased array transducer and manufacturing method

An ultrasonic phase control and transducer technology, which is applied in the direction of the fluid using vibration, can solve the problem that the medical probe cannot be directly applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

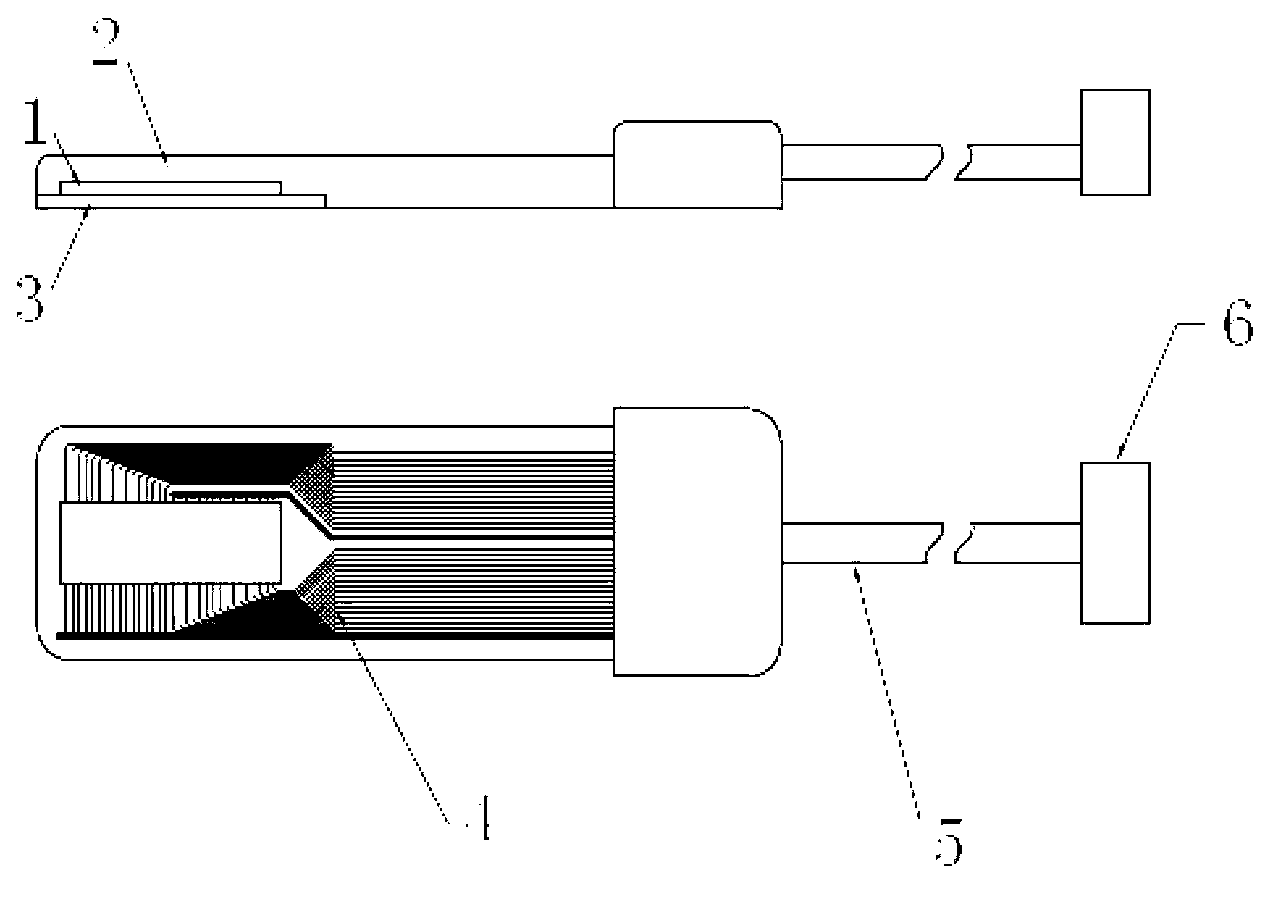

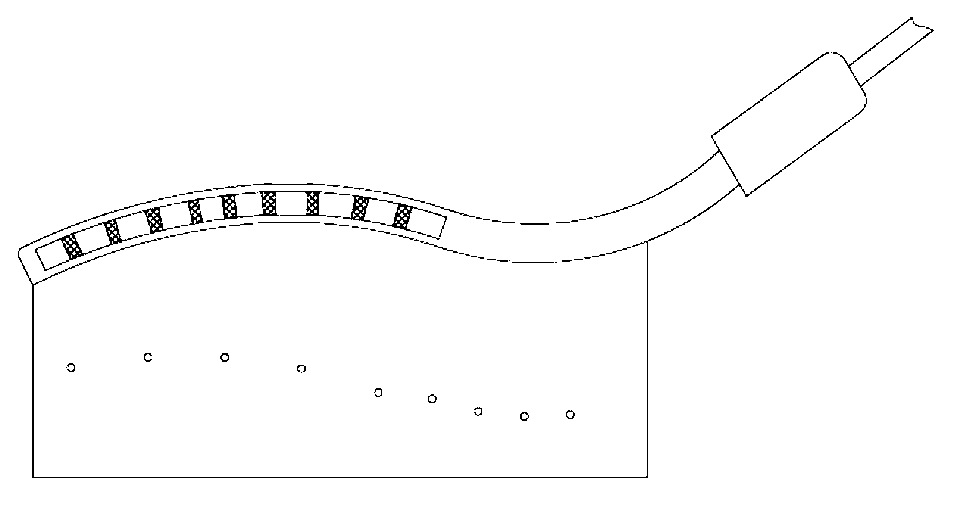

[0028] This embodiment provides a flexible ultrasonic phased array transducer, see figure 1 , is a transducer structure, including a flexible piezoelectric ceramic composite wafer, a damping back material, a matching layer, a flexible circuit board, a coaxial cable and a probe interface; the matching layer, a flexible piezoelectric ceramic composite wafer and a damping back The materials are sequentially bonded together to form an acoustic laminate; the flexible circuit board is connected to the flexible piezoelectric ceramic composite material chip, and a multi-core coaxial cable is drawn from the flexible circuit board to the probe interface.

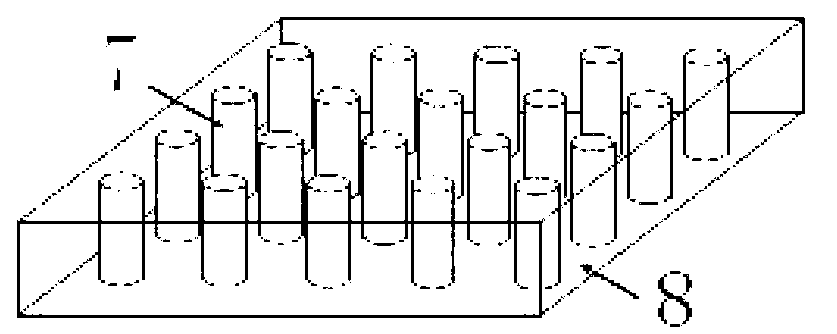

[0029] The flexible piezoelectric ceramic composite material is a piezoelectric ceramic body wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com