Washing machine

A net washing machine and net washing technology, applied in the field of net washing machines, can solve the problems of high net washing cost, limited cleaning capacity of vertical net washing machines, high labor intensity, etc., so as to prevent working environment pollution and avoid secondary manual cleaning. , Improve the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

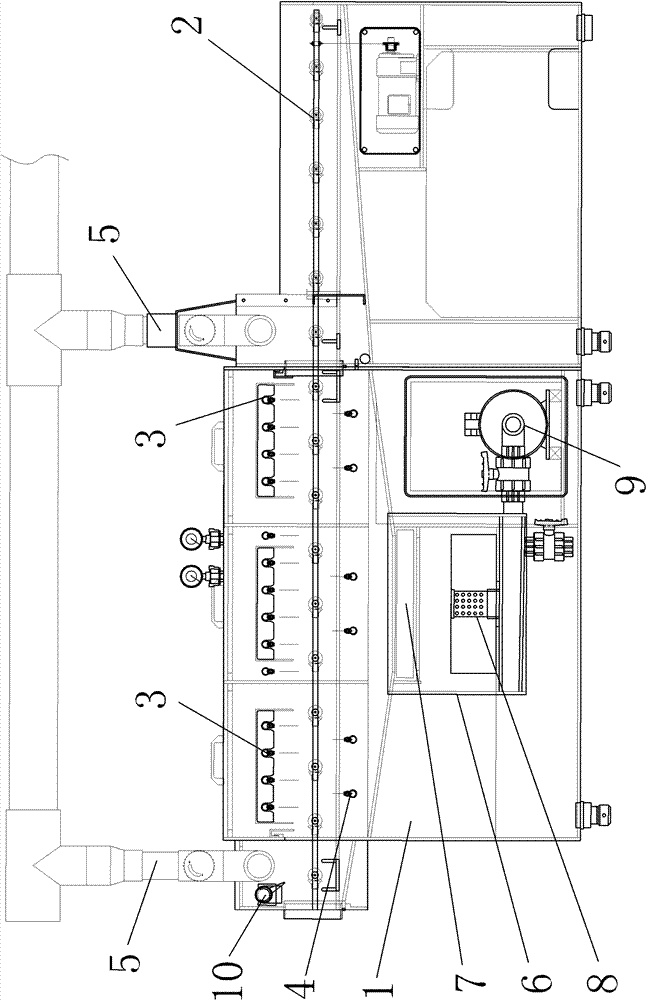

[0015] Such as figure 1 The net washing machine shown in the present invention includes: a closed casing 1, a roller conveying mechanism 2, an upper spray mechanism 3 and a lower spray mechanism 4 for spraying net washing water, and an exhaust pipe 5. Wherein, the roller conveying mechanism 2 , the upper spraying mechanism 3 and the lower spraying mechanism 4 are all arranged inside the casing 1 , and the roller conveying mechanism 2 is used to convey the screen from the inlet end of the casing 1 to the outlet end. The upper spraying mechanism 3 and the lower spraying mechanism 4 are respectively arranged above and below the moving path of the screen plate, and both are composed of a spraying pipe and a plurality of nozzles arranged on the spraying pipe. During specific implementation, the number of nozzles of the upper spray mechanism 3 is greater than the number of nozzles of the lower spray mechanism 4, which can prevent the jamming problem caused by the excessive pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com