Design method for covering tension mechanical device

A technology of a mechanical device and a design method, which is applied in the field of stress skin tensioning of passenger cars, can solve the problems of skin sagging, insufficient skin tension, and difficulty in ensuring the appearance flatness and weldability of the skin, so as to ensure the paint surface. The effect of flatness and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

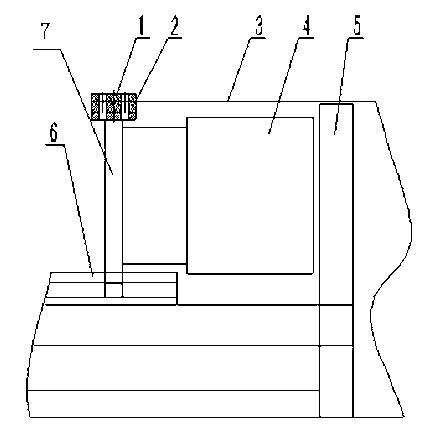

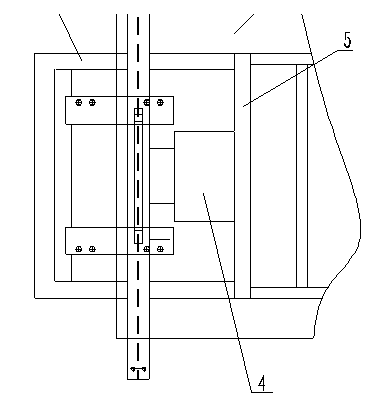

[0014] Such as figure 1 , 2 As shown, a skin tensioning mechanical device includes a punch 1, a female mold 2, a jack 4, a support frame 5, a guide rail 6, a support rod 7, and the convex and concave molds of the male mold 1 and the female mold 2 are connected together by bolts. The bottom of the clamping device is fixedly connected to the top of the support rod 7, the bottom of the support rod 7 is placed on the guide rail 6, and the guide rail 6 is fixedly connected to the base of the support frame 8. The jack 4 is set on the support frame 5 and the support rod 7. between. The jack 4 is a hydraulic jack.

[0015] The free stroke of the hydraulic jack is 100mm, and the guide rail 6 is used to ensure its smooth operation. One end of the stress skin 3 (length up to 13m) is fixed on the clamping device composed of the punch 1 and the die 2. Under the external force of the jack, Move to the left and pull the stress skin 3 so that one end of the stress skin 3 is fixed, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com