Repair welding positioning device for automobile instrument panel bracket

A technology for automobile dashboards and positioning devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the accuracy of welding positions, jumping of workpieces to be processed, and inability to meet precision assembly, so as to ensure accuracy and avoid The workpiece jumps and meets the effect of precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

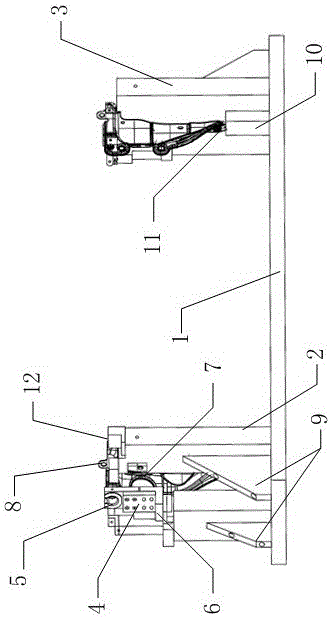

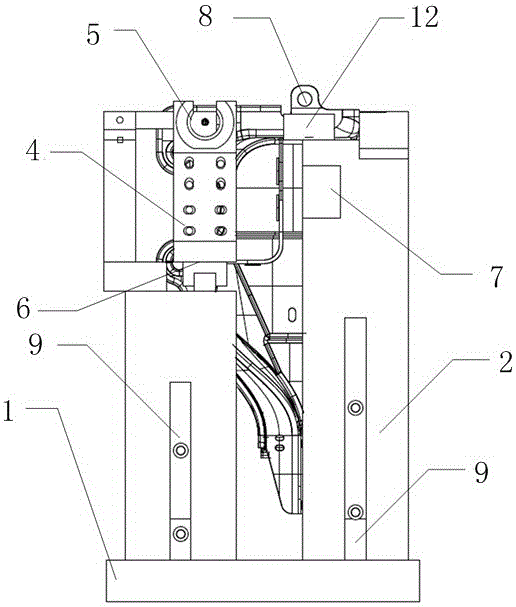

[0014] A kind of repair welding positioning device of automobile instrument panel bracket of the present embodiment, such as Figure 1~Figure 2 As shown, including the base 1, the left and right ends of the base 1 are symmetrically provided with a left support frame 2 and a right support frame 3, and the tops of the left support frame 2 and the right support frame 3 are symmetrically provided with a detection panel 4 and a guide sleeve 5 respectively. , the slide rail assembly 6 and the magnet positioning device 7, the bottom of the detection panel 4 is connected with the left support frame 2 and the right support frame 3 respectively through the slide rail assembly 6, and slides left and right relative to the left support frame 2 and the right support frame 3, and the detection panel The head of 4 is provided with guide sleeve 5; Magnet positioning device 7 is embedded in left support frame 2 and right support frame 3, and the top of left support frame 2 and right support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com