Production line of graph code steel plate integrating spray coating and screen printing

A technology of screen printing and production line, which is applied in the direction of screen printing machines, printing machines, printing machines, etc. It can solve the problems of aggravating the difficulty of printing, restricting the application of screen printing technology, and the steel plate cannot be completely flat, and achieve the effect of reducing the difficulty of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

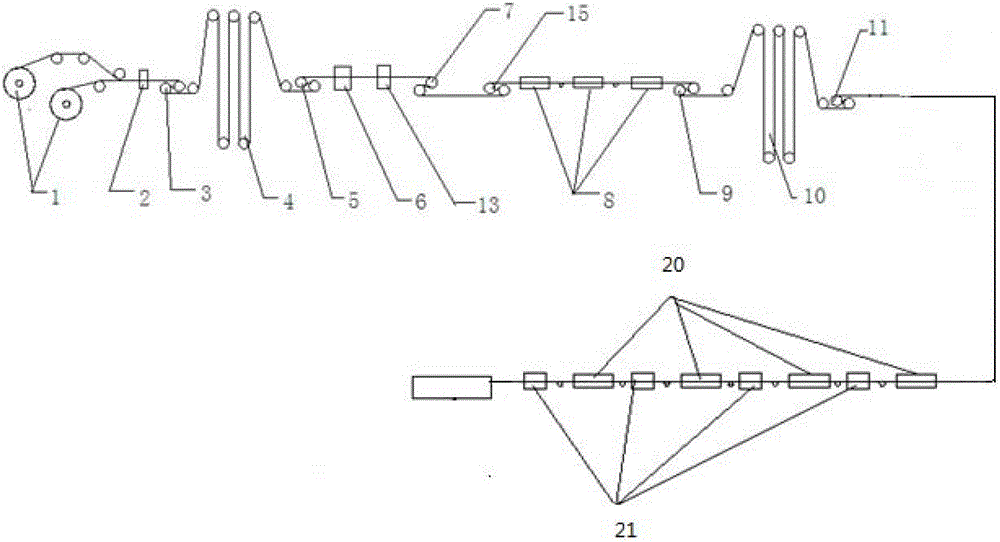

[0024] Such as figure 1 As shown, this embodiment provides a production line for patterned steel plates that integrates spraying and screen printing, including a spraying section for spraying the primer for the steel strip and a steel strip after the spraying section for spraying the primer. With screen printing section for screen printing.

[0025] The spraying section includes the following equipment: an uncoiler 1, which is used to uncoil the crimped steel strip, and trims the steel strip; 1. The front and rear steel strips after uncoiling are connected together to ensure the continuity of the process after replacing the steel coils; the first tension roller 3 is used to make the steel strips stitched by the sewing machine 2 run smoothly ; The entrance looper 4, the entrance looper 4 is wound by steel strips, used to ensure that the process section does not stop when the uncoiler 1 is uncoiled and the sewing machine 2 is stitched; the second tension roller 5, the second T...

Embodiment 2

[0032] This embodiment is an improvement on the basis of the picture code steel plate production line provided in embodiment 1, and the only difference between it and embodiment 1 is that the leveling device is different. In this embodiment, several through holes are provided on the printing platform corresponding to the storage position of the steel strip, and a fan is provided at the bottom of the printing platform, and the fan can pass through the Through hole suction.

[0033] When using this leveling method for leveling, since the printing table is provided with several through holes, and when the steel belt is uneven, there will be a gap between the printing table and the air suction through the fan, and the wind will It can flow to the fan through the through hole, so that a negative pressure zone is generated in the gap between the steel belt and the printing table, so that the steel belt is adsorbed on the printing table, and then leveling is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com