A temperature-adjusting and humidity-adjusting paint and a preparation method thereof

A temperature-adjusting and humidity-regulating coating technology, which is applied in the field of preparation of temperature-humidity-regulating coatings, can solve the problems of excessive harmful components, harmful to human body, and polyvinyl alcohol harmful to human body, and achieve excellent fire prevention and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

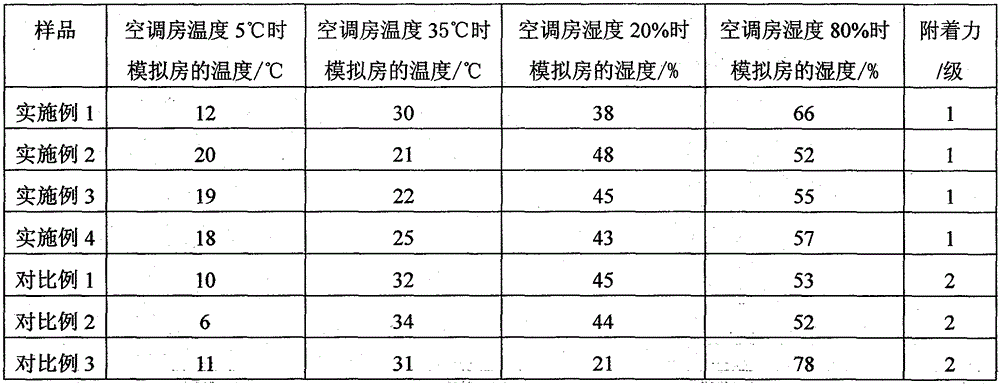

Examples

Embodiment 1

[0029] 1. Preparation of primer: In parts by mass, 100 parts of aluminum dihydrogen phosphate, 10 parts of perlite, 10 parts of calcium carbonate, 0.02 parts of methyl silicone oil, 0.04 parts of sodium tripolyphosphate, 0.04 parts of methyl trimethoxy Silane, 50 parts of deionized water, stir and disperse to obtain thermal insulation primer.

[0030] 2. Preparation of middle paint: in parts by mass, mix 100 parts of aluminum dihydrogen phosphate and 10 parts of Na 2 SO 4 ·10H 2 O, 10 parts of calcium carbonate, 0.02 parts of methyl silicone oil, 0.04 parts of sodium tripolyphosphate, 0.04 parts of methyl trimethoxysilane, 50 parts of deionized water, stirring and dispersing to obtain a phase change energy storage medium paint.

[0031] 3. Preparation of top coat: In parts by mass, mix 100 parts aluminum dihydrogen phosphate, 5 parts graphite flakes, 20 parts diatomaceous earth, 20 parts calcium carbonate, 2 parts zinc powder, 0.02 parts methyl silicone oil, 0.04 parts three Sodium...

Embodiment 2

[0033] 1. Preparation of primer: in parts by mass, mix 100 parts of silica sol, 100 parts of mineral wool, 100 parts of gypsum, 1 part of dimethyl silicone oil, 2 parts of hydroxymethyl cellulose, 2 parts of vinyl dimethyl ethyl Oxysilane, 800 parts of deionized water, stir and disperse to obtain heat insulation primer.

[0034] 2. Preparation of middle paint: in parts by mass, mix 100 parts of silica sol, 100 parts of paraffin, 100 parts of gypsum, 1 part of dimethyl silicone oil, 2 parts of hydroxymethyl cellulose, 2 parts of vinyl dimethyl ethoxylate Base silane, 800 parts deionized water, stir and disperse to obtain phase change energy storage paint.

[0035] 3. Preparation of top coat: in parts by mass, 100 parts of silica sol, 100 parts of pure acrylic emulsion, 100 parts of aluminum nitride, 100 parts of molecular sieve, 100 parts of gypsum, 20 parts of copper chloride, 1 part of dimethyl silicone oil , 2 parts of hydroxymethyl cellulose, 2 parts of vinyl dimethyl ethoxy si...

Embodiment 3

[0037] 1. Preparation of primer: in parts by mass, 100 parts of geopolymer, 50 parts of hollow glass beads, 50 parts of gypsum, 0.5 parts of hydrophilic silicone oil, 1 part of sodium polyacrylate, 1 part of polyacrylic acid, 400 parts Stir and disperse deionized water to obtain thermal insulation primer.

[0038] 2. Preparation of middle paint: in parts by mass, 100 parts of geopolymer, 50 parts of polyol, 50 parts of talc, 0.5 part of hydrophilic silicone oil, 1 part of sodium polyacrylate, 1 part of polyacrylic acid, 400 parts of Ionized water is stirred and dispersed to obtain a phase change energy storage medium paint.

[0039] 3. Preparation of topcoat: In parts by mass, 100 parts of geopolymer, 50 parts of silicone modified pure acrylic emulsion, 50 parts of magnesium oxide, 50 parts of activated carbon, 50 parts of attapulgite, 10 parts of anatase type Titanium oxide, 0.5 parts of hydrophilic silicone oil, 1 part of sodium polyacrylate, 1 part of polyacrylic acid, 400 part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap