Underground outer wall construction joint water-stopping structure and construction method thereof

An underground structure and construction joint technology, which is applied to underwater structures, infrastructure projects, artificial islands, etc., can solve the problems of short water seepage time on the upstream surface, difficult construction quality control, easy water seepage, etc., and achieve wall quality assurance. , The effect of reducing the possibility of water seepage and speeding up the construction and installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

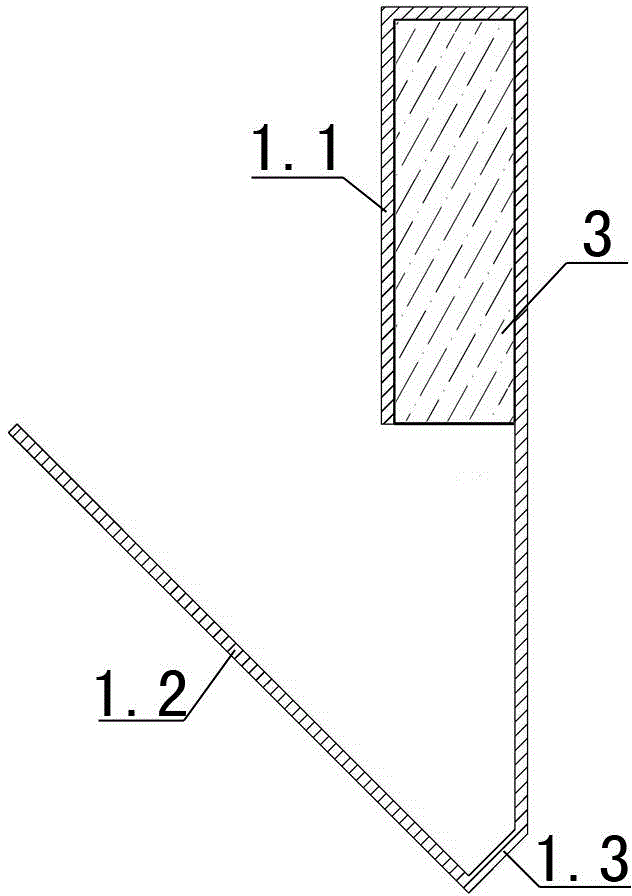

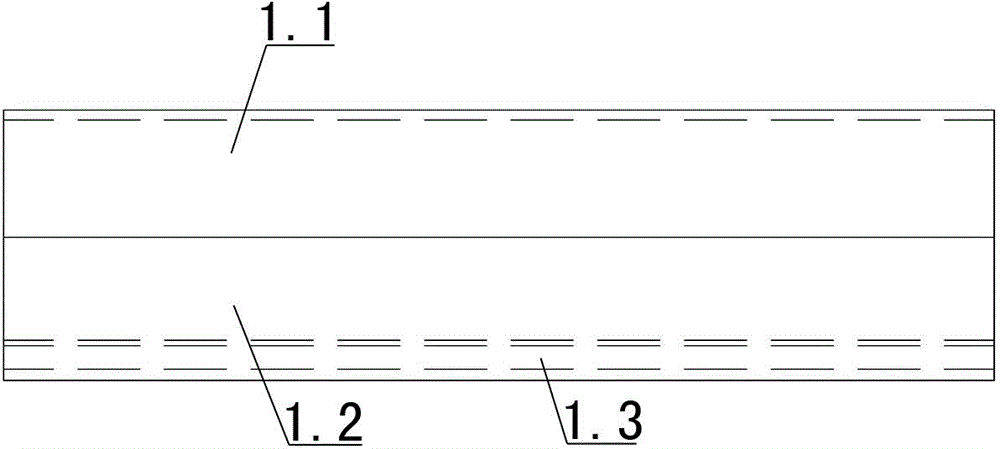

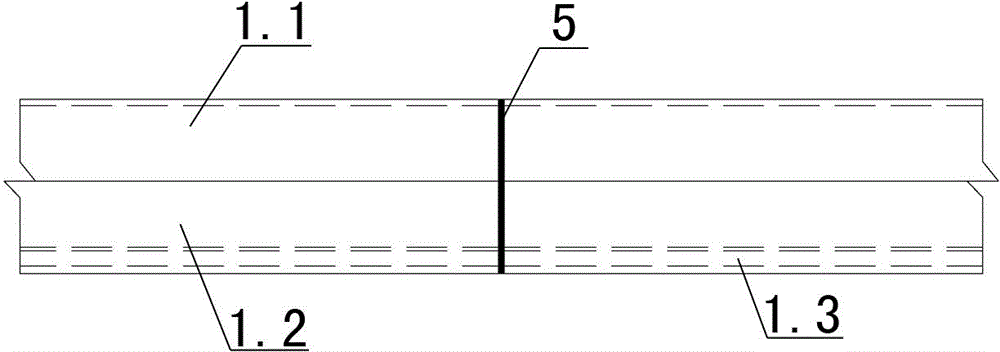

[0035] Examples see Figure 1-2 As shown, a waterproof structure for the construction joints of the exterior wall of an underground structure includes a water-stop steel plate 1, and the water-stop steel plate 1 is vertically buried in the middle of the horizontal construction joint 4 along the length direction of the exterior wall. 1 It is formed by bending a whole steel plate, and is divided into upper and lower parts vertically along the horizontal construction joint 4. The upper part has an inverted U-shaped right-angle hook 1.1 exposed on the upper surface of the horizontal construction joint 4 and bent to the side facing the water , the lower part of which is pre-embedded in the concrete 6 poured on the outer wall and bent to the side facing the water with a bend 1.3 oblique bend 1.2, the right-angle hook 1.1 is filled with a water-swellable water-stop strip 3, the The distance between the end of the right-angle hook 1.1 and the end of the oblique flange 1.2 is not less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com