Location method for nano materials synthesis used catalyst

A technology of nanomaterials and catalysts, which is applied in the field of positioning of catalysts for nanomaterial synthesis, can solve the problems of no deposition, substrate contamination, and no practical value, and achieves improved selectivity, strong practicability, and improved Effect of deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the location of the catalyst for the synthesis of carbon nanotubes

[0037] 1. The positioning of the catalyst

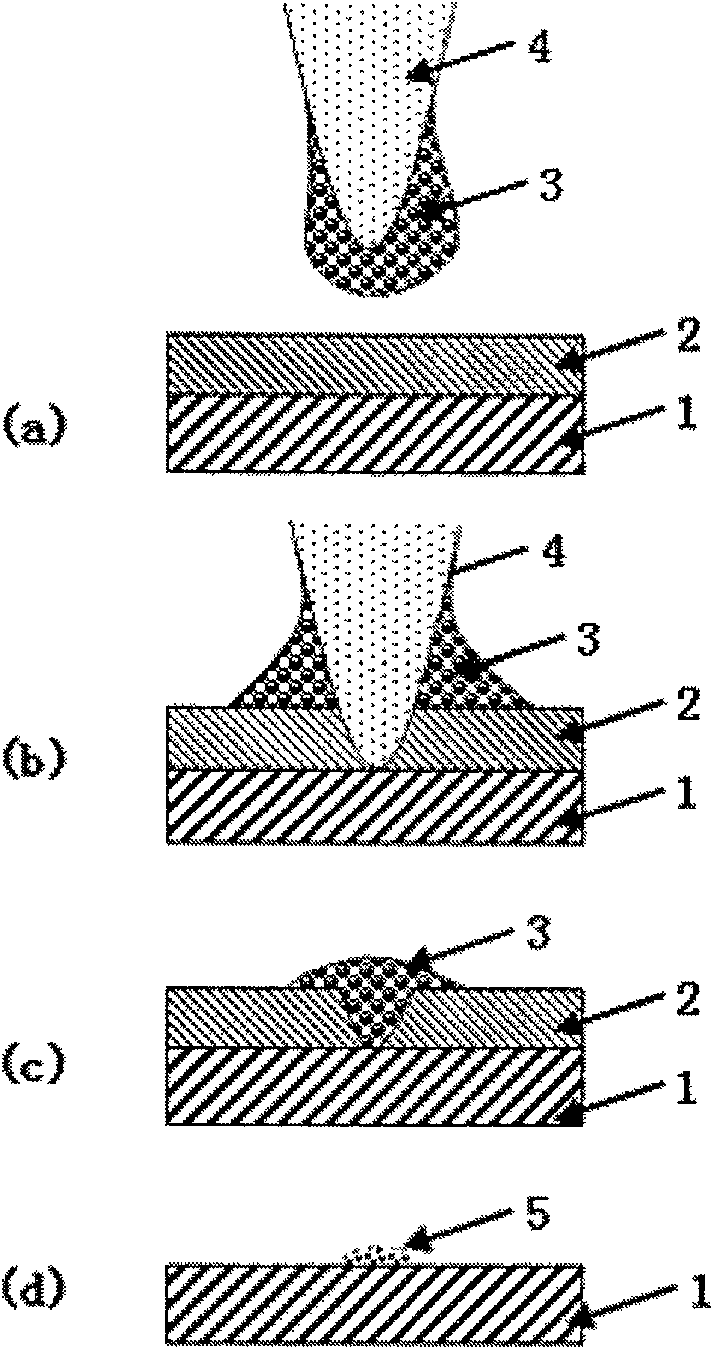

[0038] A schematic diagram of the process flow for positioning a catalyst is shown in figure 1 shown. in figure 1 In (a) the needle tip 4 with the catalyst solution 3 approaches the substrate 1 spin-coated with the photoresist 2; figure 1 In (b), the needle tip 4 with the catalyst solution 3 pierces the photoresist 2, and the catalyst solution 3 contacts the substrate 1; figure 1 In (c) after the tip 4 of the atomic force microscope leaves, the catalyst solution 3 remaining in the groove of the scratched photoresist 2 contacts the substrate 1; figure 1 In (d) is the catalyst 5 positioned on the surface of the substrate 1 obtained after stripping the photoresist and burning.

[0039] The specific steps are as follows:

[0040] 1. Clean the substrate: use quartz as the substrate, cut the quartz into small pieces of 1cm×1cm square, with a thi...

Embodiment 2

[0047] Embodiment 2, the positioning of the catalyst for the synthesis of carbon nanotubes

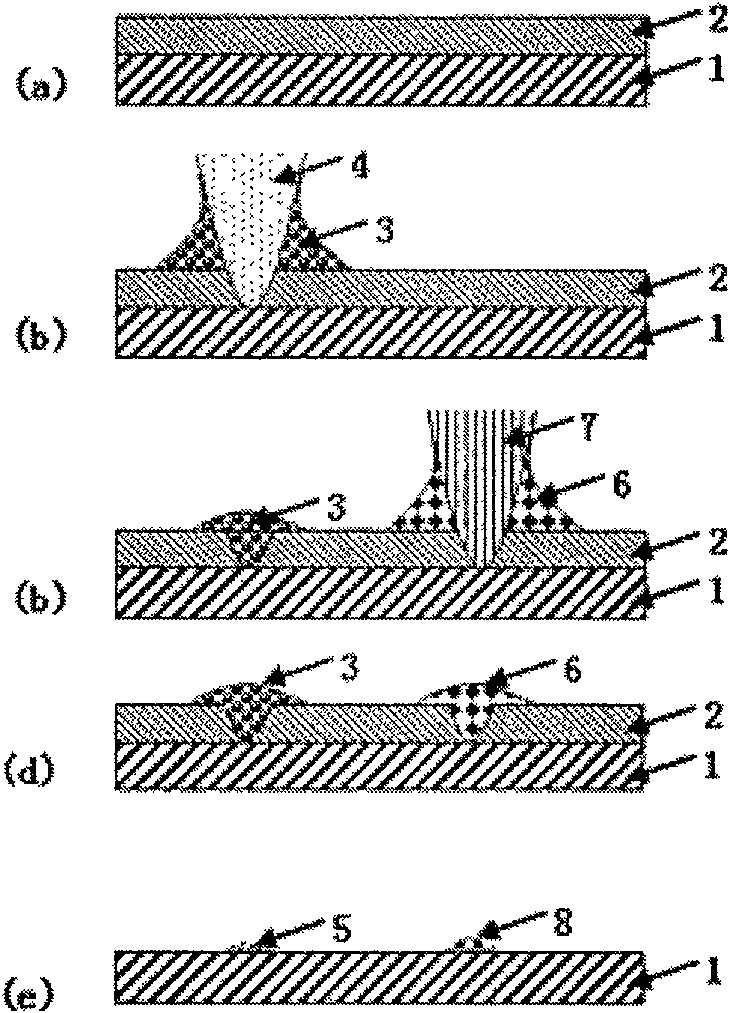

[0048] The process flow diagram of the method for positioning the two catalysts is shown in figure 2 shown. figure 2 Middle (a) is the substrate 1 that is spin-coated with photoresist 2; figure 2 In (b), the needle tip 4 with the first catalyst solution 3 scratches the photoresist 2, and the first catalyst solution 3 contacts the substrate 1; figure 2 In (c) after positioning the first catalyst solution 3, use the needle tip 7 with the second catalyst solution 6 to scratch the photoresist 2, and the second catalyst solution 6 contacts the substrate 1; figure 2 (d) is the first catalyst solution 3 and catalyst solution 6 positioned in the groove of the photoresist 2; figure 2 (e) is catalyst 5 (obtained from catalyst solution 3) and catalyst 8 (obtained from catalyst solution 6) positioned on the surface of substrate 1 after peeling and burning.

[0049] 1. Using quartz as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com