Prefabricated concrete structure architecture electric pre-buried laying method

A concrete structure and building electrical technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problem that the cast-in-place layer of the pipeline cannot cover the intersection of the pipeline, the accurate positioning of the junction box and the box, and the construction quality of the cast-in-place layer. problems such as hidden dangers, to achieve the effect of reducing labor input, improving construction efficiency, and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below with reference to accompanying drawing and embodiment:

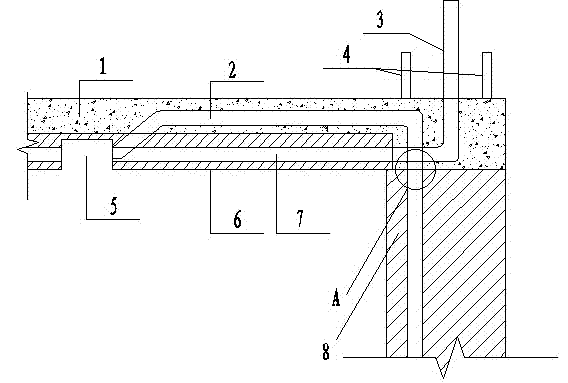

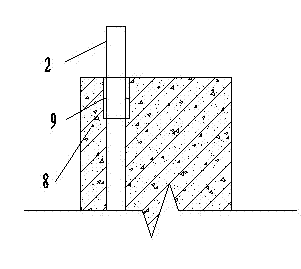

[0021] attached figure 1 , 2 It can be seen that a prefabricated concrete structure building electrical pre-embedded layout method includes the construction of the prefabricated slab 6, the construction of the prefabricated wall 8 and the construction of the roof cast-in-place layer 1, and the prefabricated slab 6 is provided with weak current communication line pipes and sockets Pipeline circuit and air-conditioning socket pipeline circuit 7; the roof cast-in-place layer 1 is provided with a lighting circuit pipe and a main line pipe 2; the prefabricated board 6 is prefabricated with a light box 5 for electric lamps, and the line pipe is reserved in the light box 5 Throw out the surface layer of the prefabricated board 6 and connect it with the lighting circuit in the cast-in-place layer 1; the joints of the prefabricated board 6 are provided with a wire pipe in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com