Method and excavating impulsion shovel used for simultaneously achieving coal breaking and surface cleaning with one time of impulsion

A shovel and surface cleaning technology, applied in the field of mining shovel, can solve the problems of poor operation flexibility, large resistance, short life, etc., and achieve the effects of simple and compact structure, increased impact force, and long impact life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

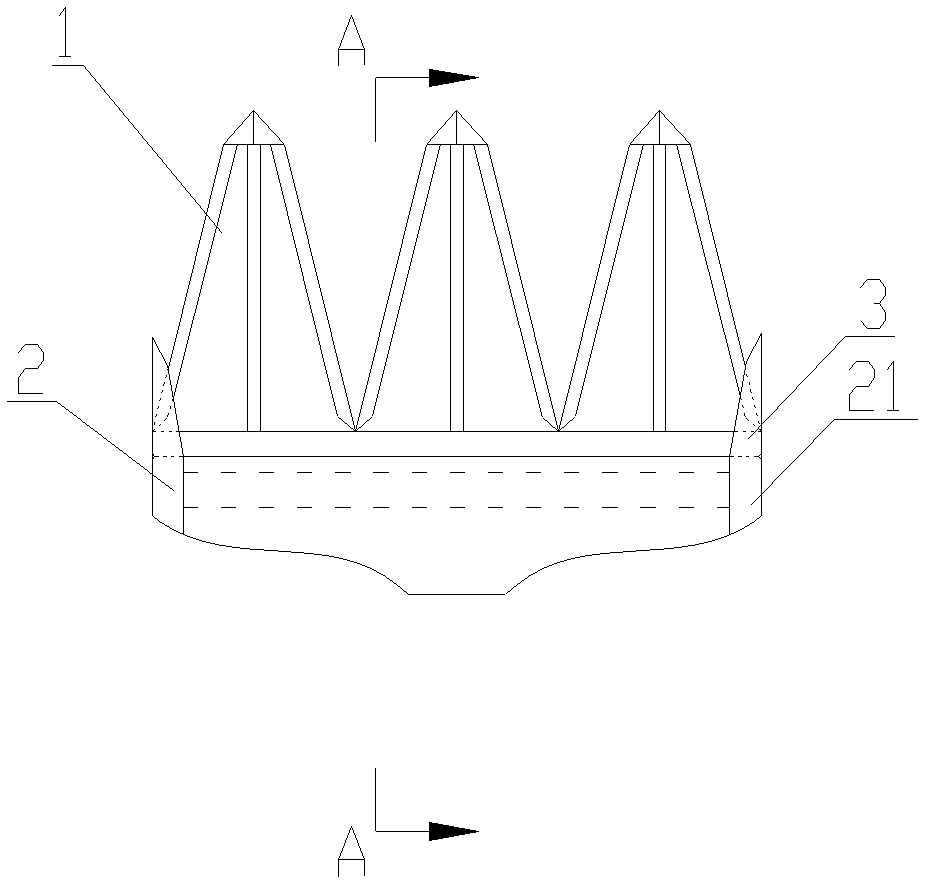

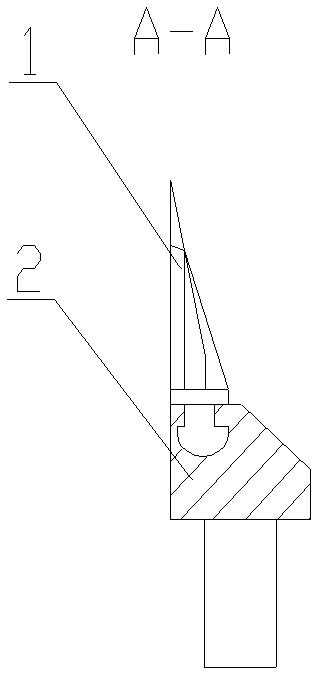

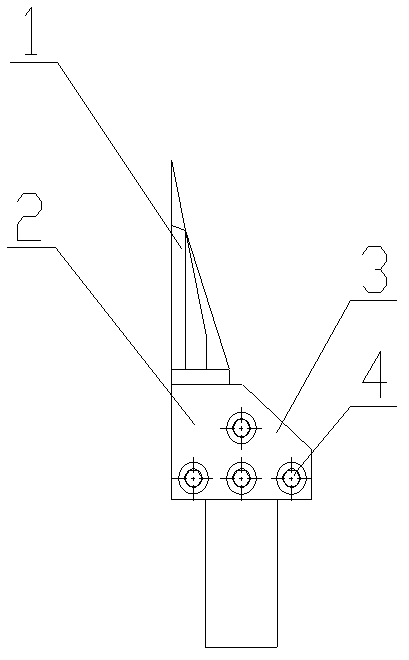

[0075] Figure 1 to Figure 13 It is the mining shovel described in this embodiment. The excavation shovel includes a part for punching and removing coal and a fixed part. The part for punching and dropping coal and clearing the surface is a shovel tooth 1, and the mining shovel is provided with a plurality of shovel teeth 1, and the shovel teeth 1 are located at the front of the mining shovel, and are fixedly connected with the top end surface of the fixed component. The shoveling teeth 1 include a plurality of long shoveling teeth and short shoveling teeth alternately arranged on the fixed part, and each shoveling tooth is located on the same plane. Simultaneously, the left and right sides of the shovel are also respectively fixed with shovel teeth 21, which play the role of cleaning the upper and lower coal surfaces. The side shovel teeth 21 are perpendicular to the shovel or form a certain angle with the shovel. At this time, all the shovel teeth are spaced in the shape o...

Embodiment 2

[0085] Cutting edges are provided on both sides and lower parts of the shovel teeth. When the head of the shovel teeth hits the falling coal, the side cutting edges and the lower side cutting edges complete the cleaning work at the same time.

[0086] Others are with embodiment 1.

Embodiment 3

[0088] Cutting edges are provided on both sides and the bottom of the shovel teeth. When the head of the shovel teeth hits the falling coal, the side cutting edges and the bottom cutting edges complete the cleaning work at the same time.

[0089] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com