Concave cutter of slurry balance tube push bench

A mud-water balance and pipe jacking machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as low cutter head opening ratio, insufficient cutter head rigidity and strength, inability to cut and secondary crushing of rock and soil, etc. Achieve the effect of guaranteeing life and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

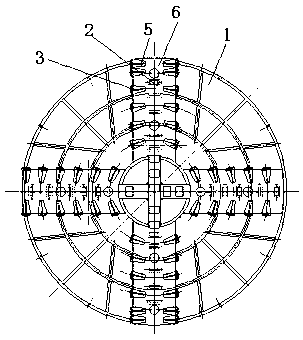

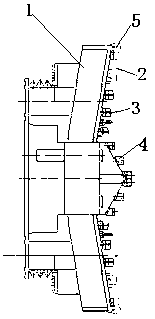

[0022] Such as figure 1 , As shown in 2, the muddy water balance pipe jacking machine of the present invention has a concave cutterhead, including a cutterhead body 1, a main cutting knife 2, a leading knife 3, and the like.

[0023] The cutterhead body 1 is welded by spokes 6, side plates, rib plates, outer edge plates, rear cover plates, wear-resistant alloy strips and support beams. The plate and the outer edge plate are connected into one; each spoke 6 is provided with a main cutting knife 2 and a leading knife 3 .

[0024] 1. The cutter head is in concave form, which can adapt to the excavation requirements of complex soil layers:

[0025] 1) The concave cutter head increases the stability of the balanced support excavation surface.

[0026] 2) It has sufficient rigidity and strength to support the excavation surface and withstand the thrust an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com