Safety type cylinder valve

A gas cylinder valve and safety-type technology, applied in the field of engineering components, can solve the problems of safety hazards for users and nearby personnel, and the lack of gas cylinder valve protection functions, etc., to eliminate safety hazards, prevent gas cylinder impact, and ensure safe use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will further describe the safety gas cylinder valve of the present invention according to specific embodiments of the present invention and accompanying drawings, but the description does not constitute a limitation of the present invention.

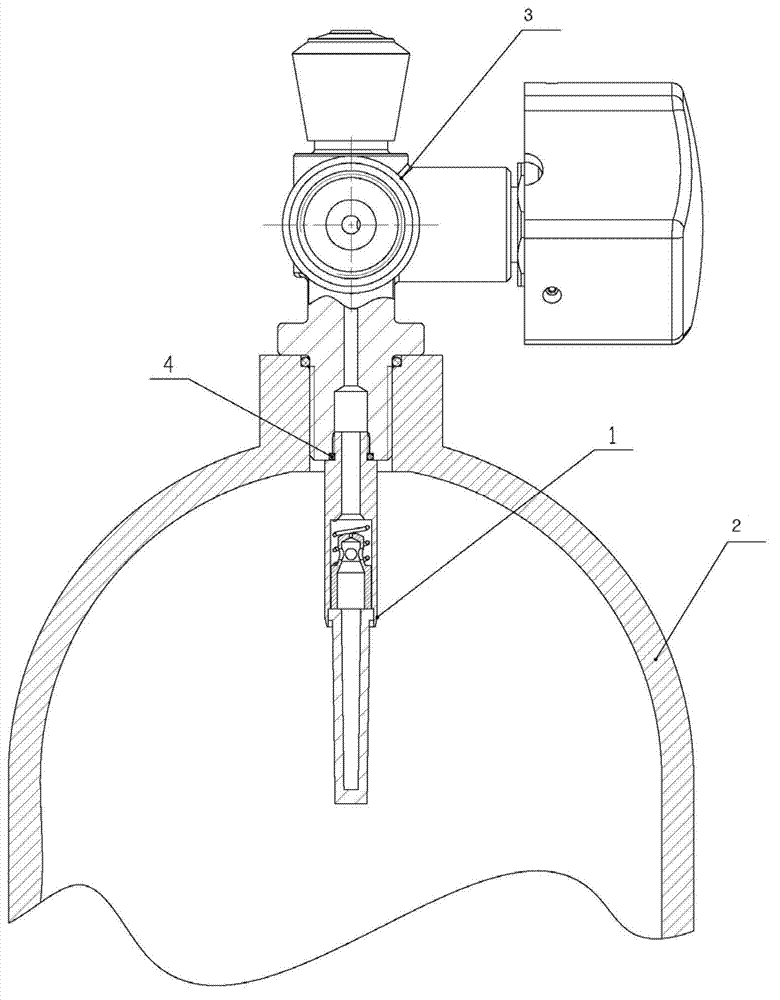

[0023] In this embodiment, an overcurrent protector 1 is installed at the bottom of the connection between the valve body 3 and the gas cylinder 2, and the overcurrent protector 1 and the valve body 3 are connected by threads and sealed with an O-shaped gasket 4, as figure 1 shown.

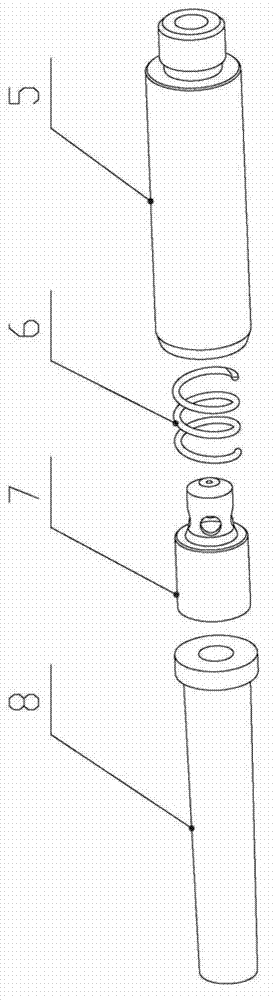

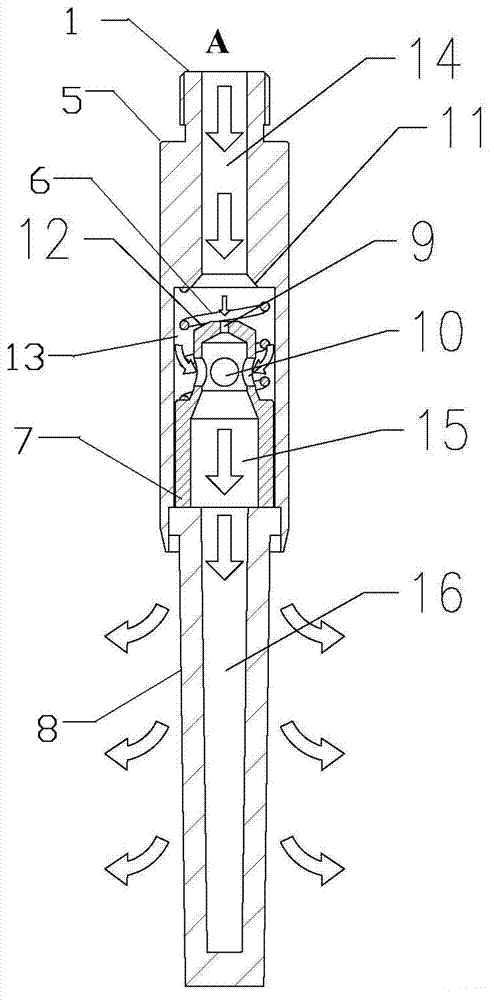

[0024] figure 2 The split structure of the overcurrent protector in this embodiment is shown. image 3 The cross-sectional structure of the overcurrent protector is shown. Such as figure 2 and image 3 As shown, the overcurrent protector 1 in this embodiment includes a restrictor body 5 , a piston limit spring 6 , a hollow restrictor piston 7 and a filter 8 . The flow restrictor main body 5 has a first cavity 14 for gas transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com