A method for preventing and controlling rockburst in filling mining

A technology of rock burst and drilling and mining, which is applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of limited construction space, low filling efficiency, and high filling cost, and achieve the effect of improving the degree of compaction and strong support performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

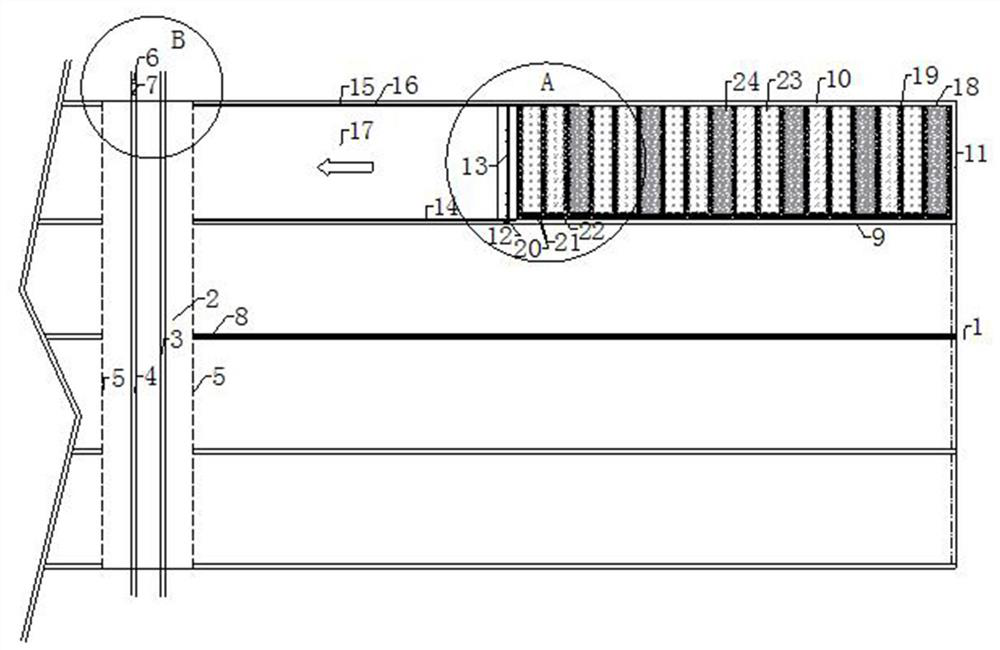

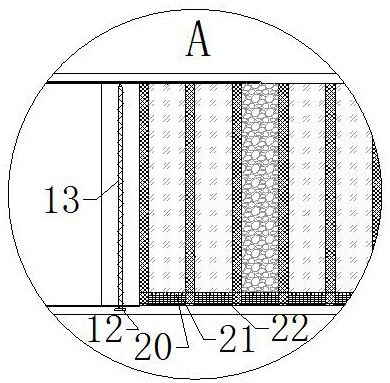

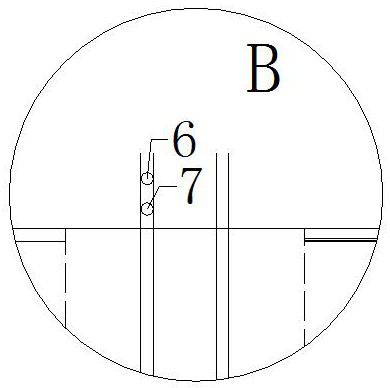

[0031] The technical solutions of the present invention will be described in more detail below in combination with the accompanying drawings in the embodiments of the present invention.

[0032] Such as Figure 1-3 As shown, a method for preventing and controlling rock burst in filling mining is used for preventing and controlling rock burst in thin coal seam mining, which specifically includes the following steps:

[0033] S1, layout mining area 1, using two-wing mining method ( figure 1 The middle mainly indicates the right wing), the uphill coal pillar 2 is located in the middle of the mining area 1, and there is a mining area uphill extending upward along the inclination in the uphill coal pillar 2, the mining area uphill includes transportation uphill 3 and track uphill 4, uphill coal The boundary on both sides of the column 2 is the production stop line 5 of the working faces of the two wings;

[0034] S2, on the upper part of the coal pillar 2 in the mining area, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com