Intelligent antifog resin lenses and preparing method thereof

A technology for resin lenses and a manufacturing method, which is applied to glasses/goggles, photo-engraving process of pattern surface, optics, etc., can solve the problem of not forming long-term stable anti-fog effect, discount of resin lens anti-fog effect, and anti-fog film. layer fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

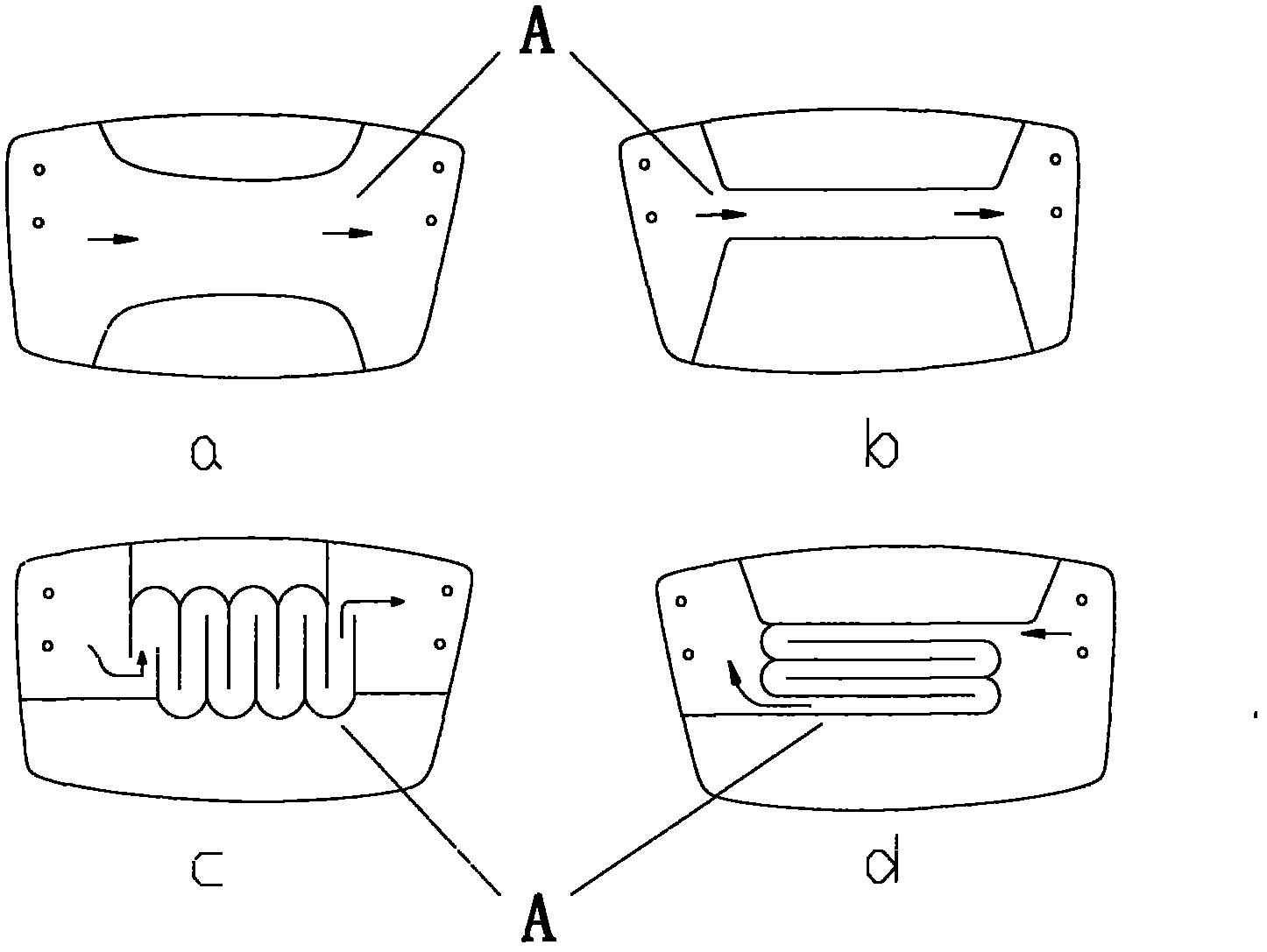

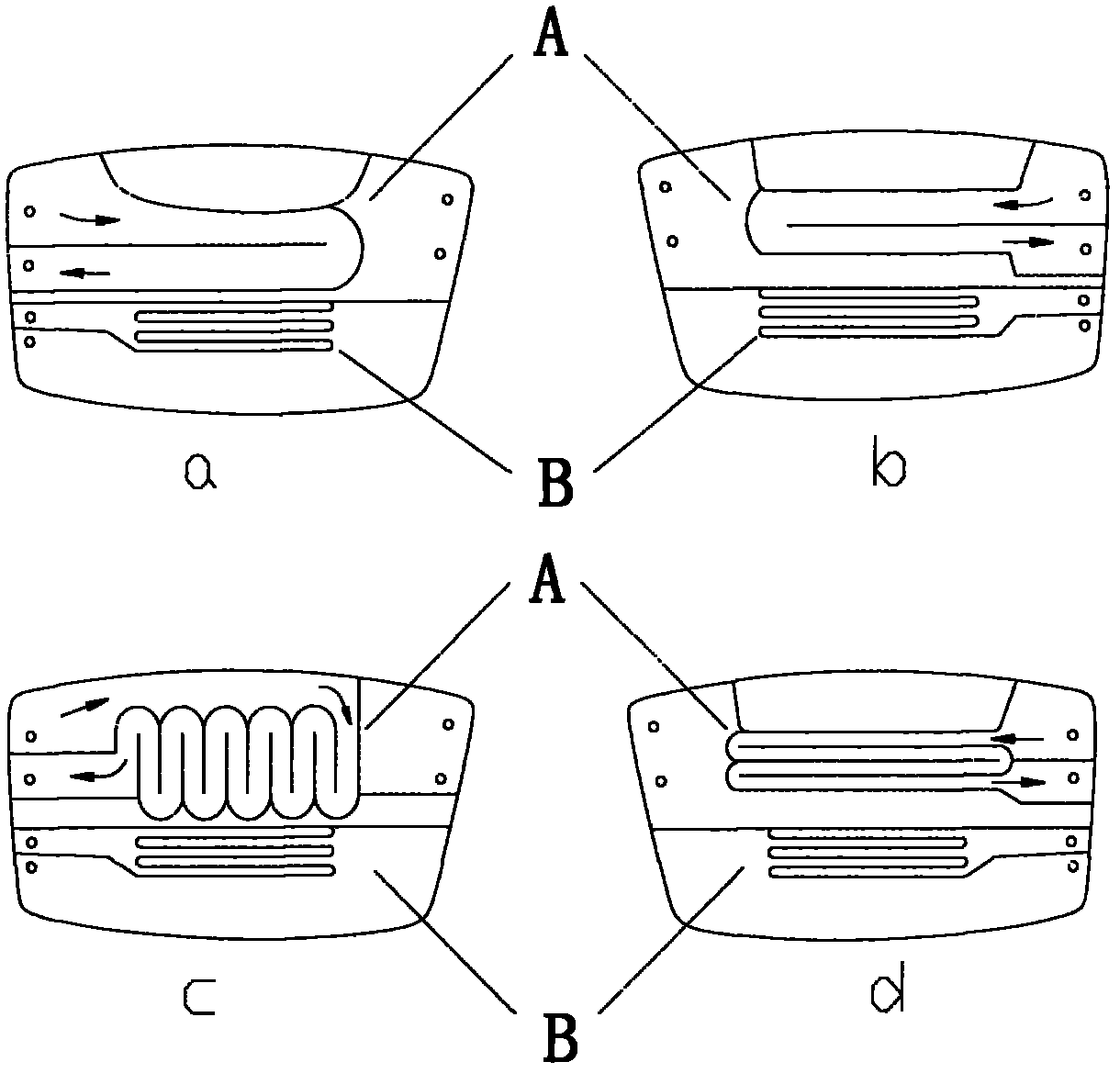

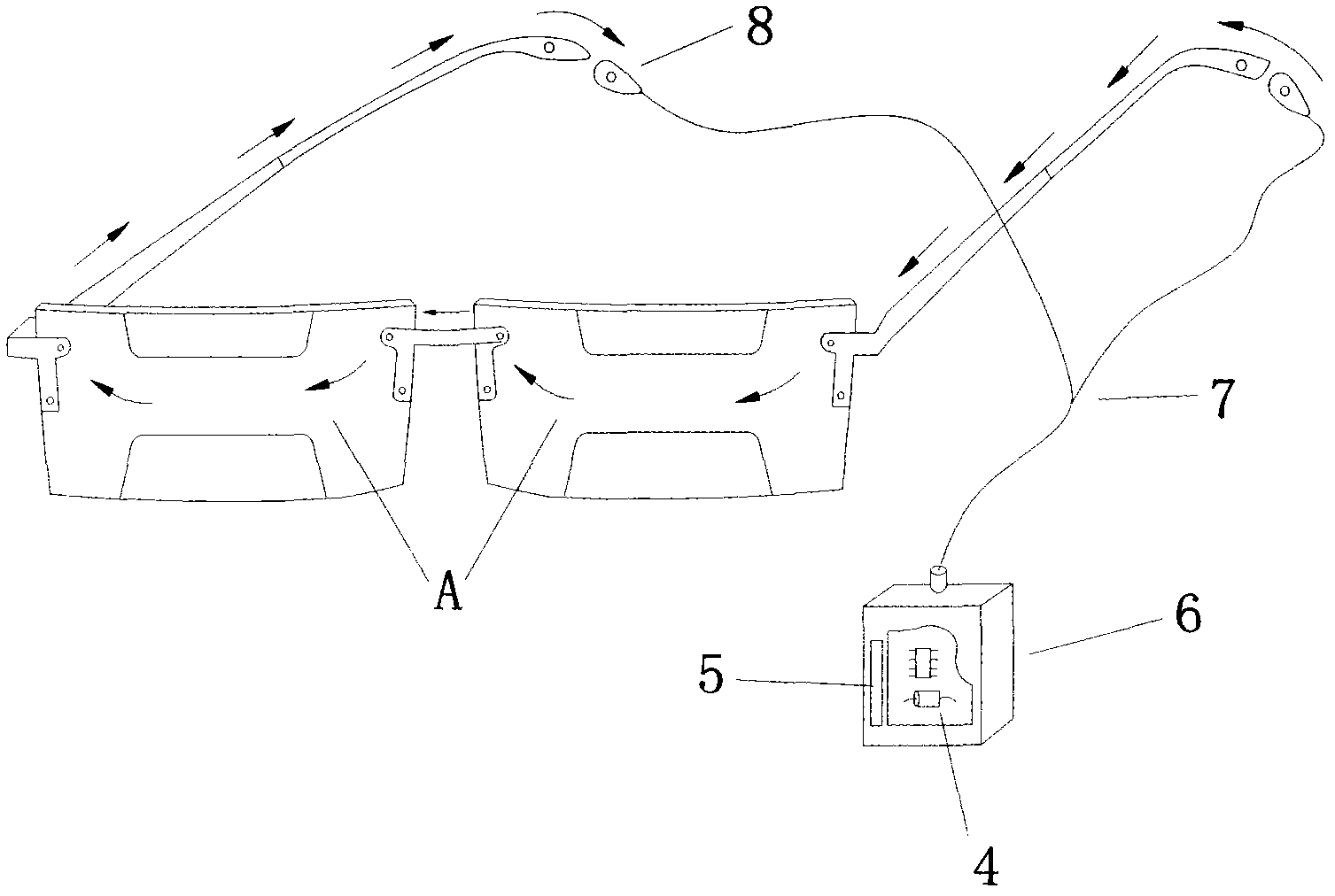

Method used

Image

Examples

Embodiment example 1

[0029] Implementation case 1: Doctors wear non-regulating anti-fog glasses during surgery. Doctors who wear myopia or presbyopic glasses for surgery should wear the anti-fog glasses before the operation. The smart anti-fog lenses are always in the state of heating and defogging during the operation, which can effectively eliminate the water vapor generated by the doctor from wearing a mask to breathe on the lenses The condensed fog keeps the lens clear and transparent, does not affect the doctor's vision, and ensures the smooth completion of the operation.

Embodiment example 2

[0030] Implementation case 2: When a nurse wearing glasses gives a patient an injection in the cold season, a large amount of lens condensation water vapor is produced due to wearing a mask to breathe, which affects the sight of the injection treatment operation. Wearing the above non-regulating anti-fog glasses, the lens will not condense water vapor, The field of vision is clear, avoiding the reduction of work efficiency or mistakes caused by unclear sight.

Embodiment example 3

[0031] Implementation case 3: In summer, when the outdoor temperature is high, and the air conditioner is turned on indoors or in the car, the temperature is low. People can't see what's in front of them. Wearing intelligent control anti-fog glasses can quickly provide heating energy in a short period of 2-3 seconds to drive away the fog on the surface of the lens and restore the transparency of the lens, which provides convenience for people's work and life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com