Optical coupling module and manufacturing method thereof

An optical coupling and optical module technology, which is applied in the coupling of optical waveguides and other directions, can solve problems such as affecting the coupling effect and the position of the optical module is prone to deviation, and achieves the effect of increasing the light-receiving range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

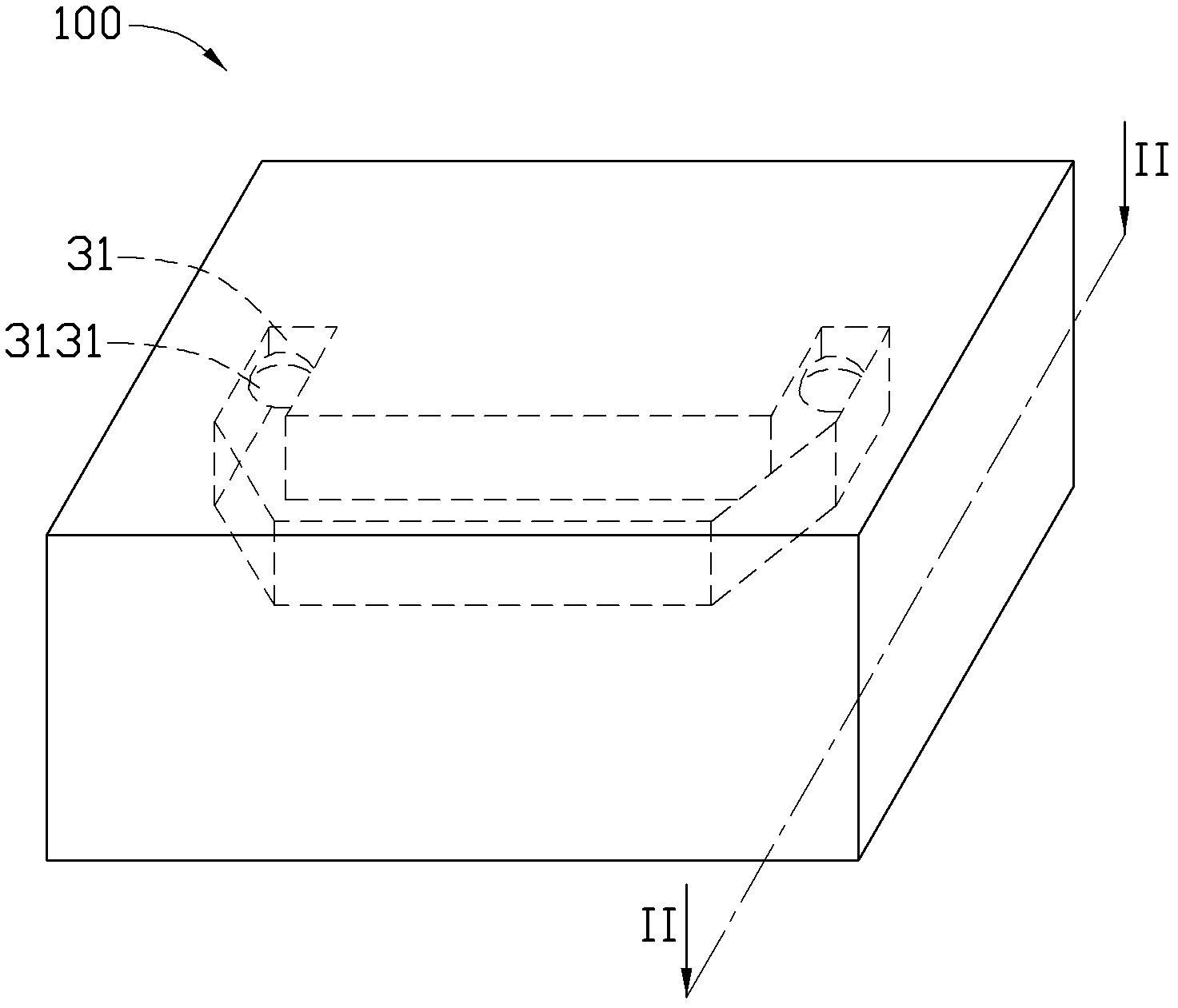

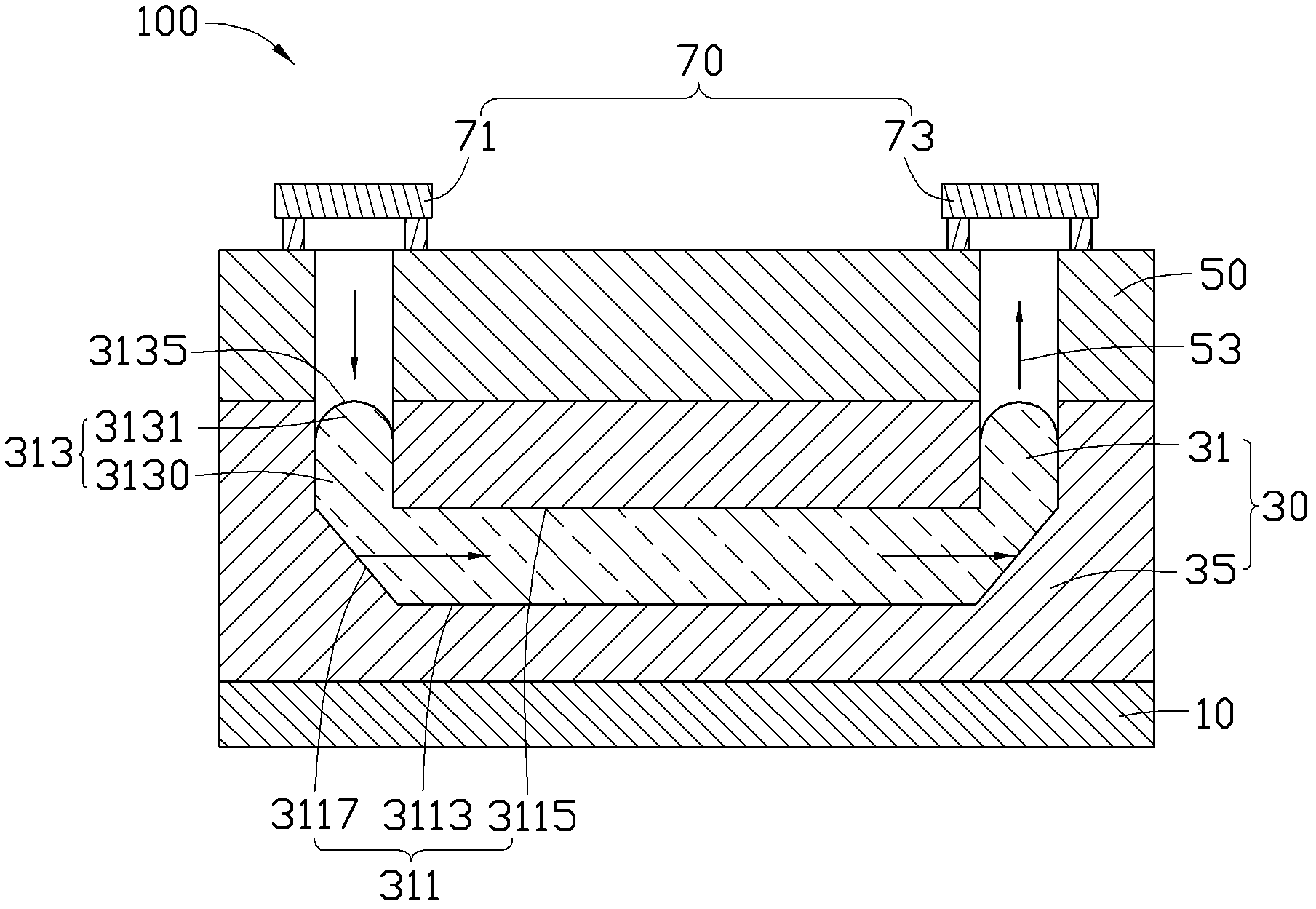

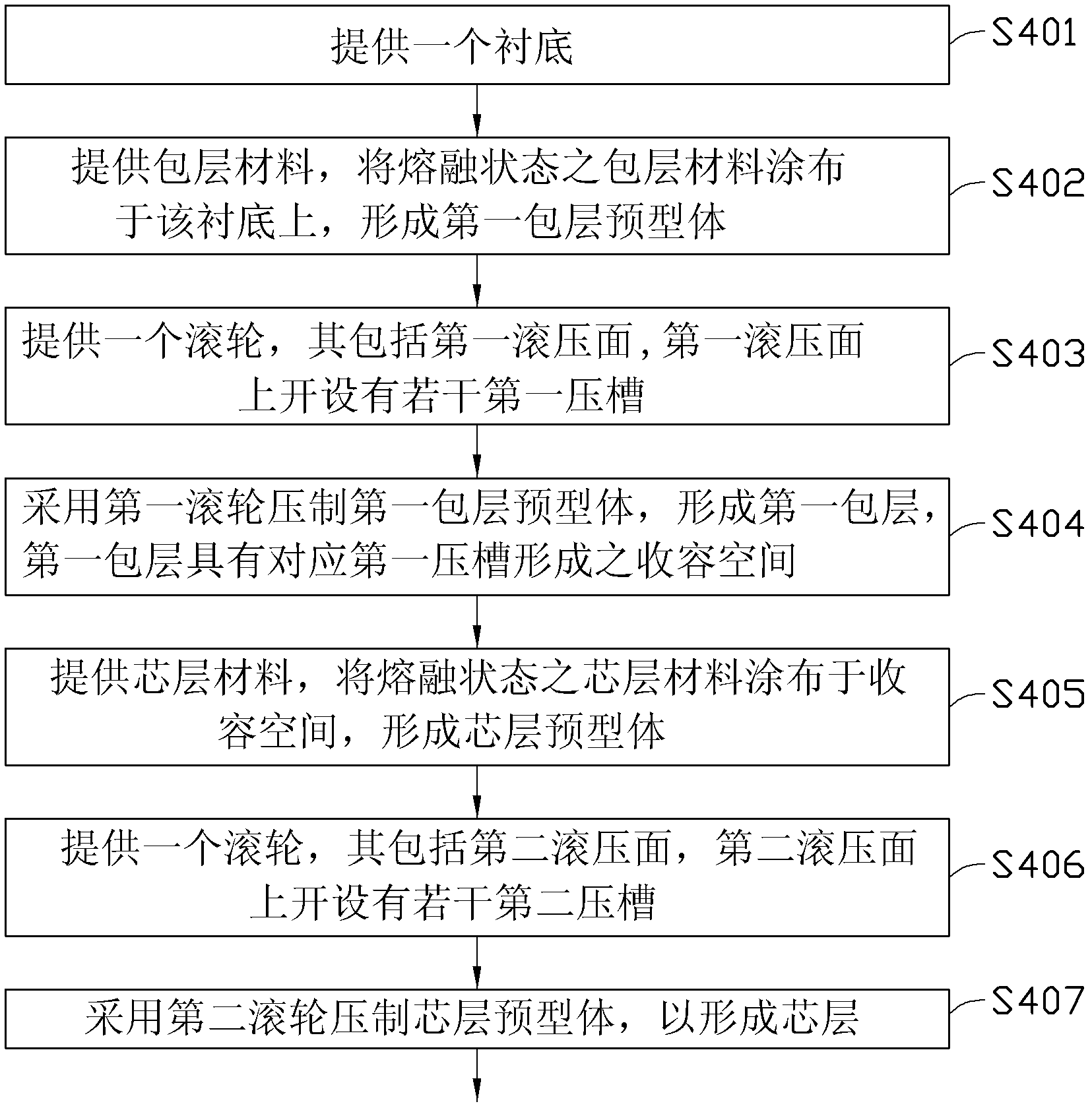

[0019] see figure 1 and figure 2 Yes, the optical coupling module 100 of this embodiment includes a substrate 10 , an optical waveguide 30 , a circuit substrate 50 and an optical module 70 . The optical waveguide 30 is located between the substrate 10 and the circuit substrate 50 , and the optical module 70 is installed on the circuit substrate 50 .

[0020] The substrate 10 may be formed of an insulating material such as resin, glass, or ceramics. The substrate 10 may also be formed of a conductive material such as metal. In this case, an insulating film needs to be formed on the mounting surface on which the integrated circuit chip is mounted. Preferably, the substrate 10 has high thermal conductivity. Circuits can also be laid on the substrate 10 for driving and controlling the operation of the optical module 70 or other components.

[0021] The optical waveguide 30 is formed on the substrate 10 for transmitting optical signals. The optical waveguide 30 includes a cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com