battery module unit

A technology for battery modules and battery cells, applied in electrical components, battery pack components, circuits, etc., can solve problems such as reduced operability, battery module deviation, and overall length of battery module units, and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

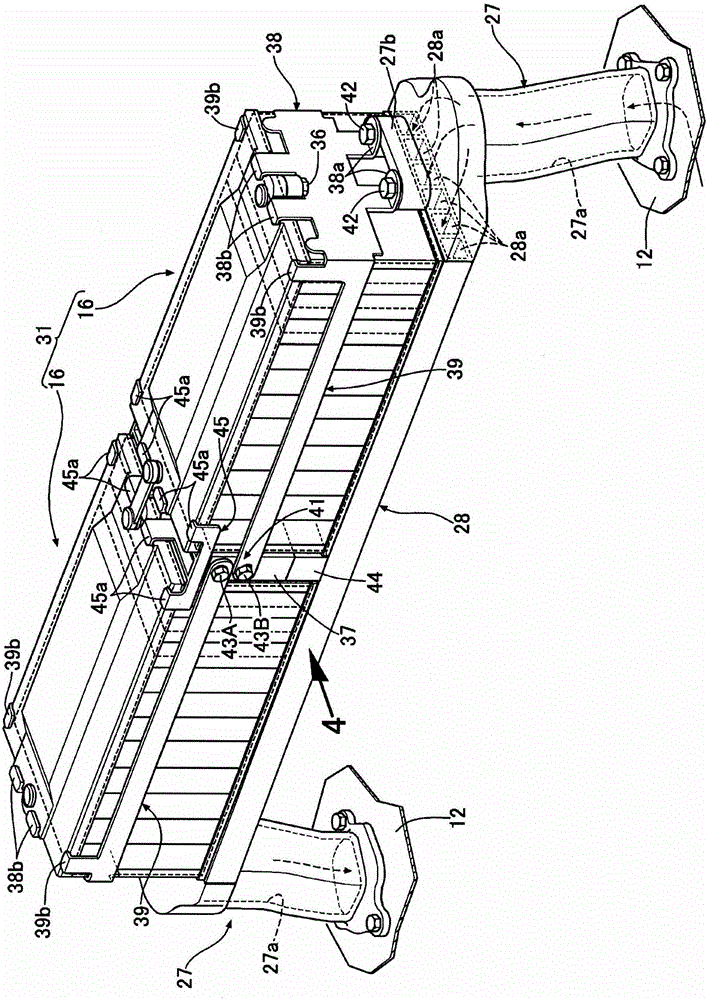

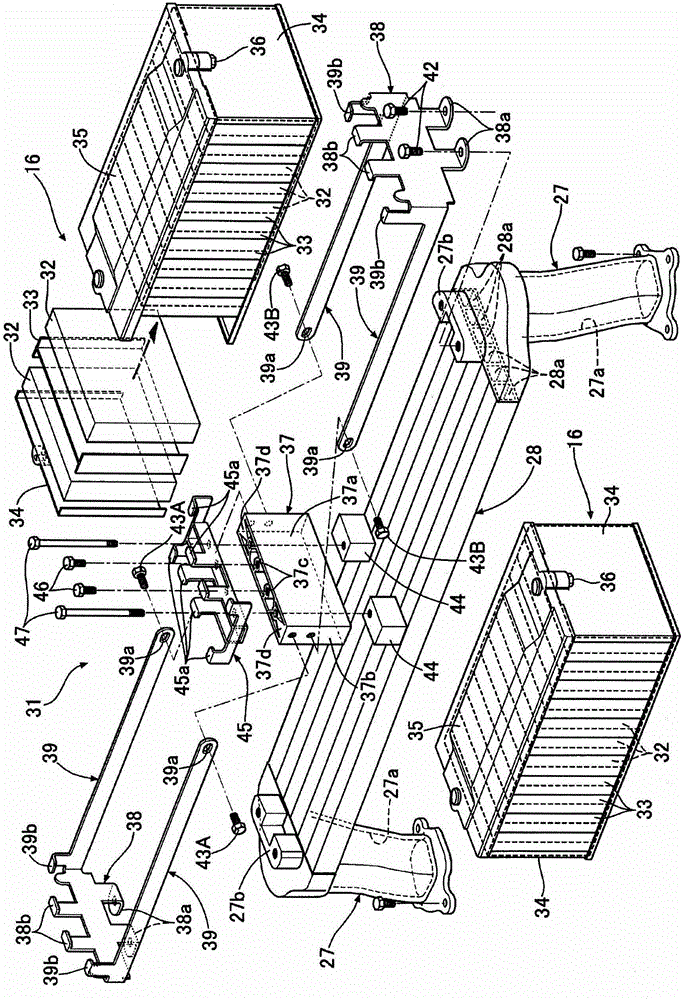

[0038] Below, based on Figure 1 to Figure 6 , the embodiment of the present invention will be described.

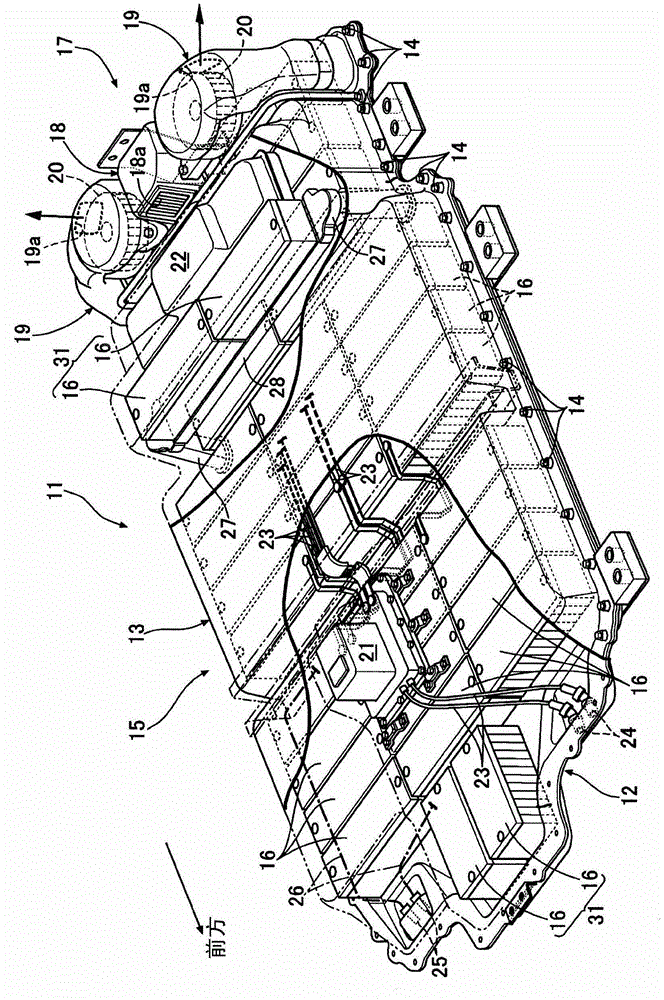

[0039] Such as figure 1 As shown, the battery pack 11 of an electric vehicle has a battery case 15 obtained by bonding a synthetic resin battery cover 13 to the upper surface of a metal battery tray 12 and fastening it with bolts 14 . . . A plurality of battery modules 16 . . . are mounted on the surface.

[0040] A cooling device 17 provided at the rear of the battery pack 11 includes a suction duct 18 disposed in the center in the vehicle width direction, and a pair of left and right discharge ducts 19 disposed on both sides of the suction duct 18 in the vehicle width direction. A cooling air inlet 18 a for sucking air outside the battery pack 11 into the inlet duct 18 is opened toward the front on the upper front surface of the inlet duct 18 . In addition, electric cooling fans 20 and 20 are respectively accommodated inside the discharge ducts 19 and 19, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com