Rolling-up mechanism of aluminum strip leftover material

A technology of rewinding mechanism and scraps, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high labor intensity, occupation of metal scraps, disorganized production site, etc., so as to reduce labor intensity and save cleaning costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

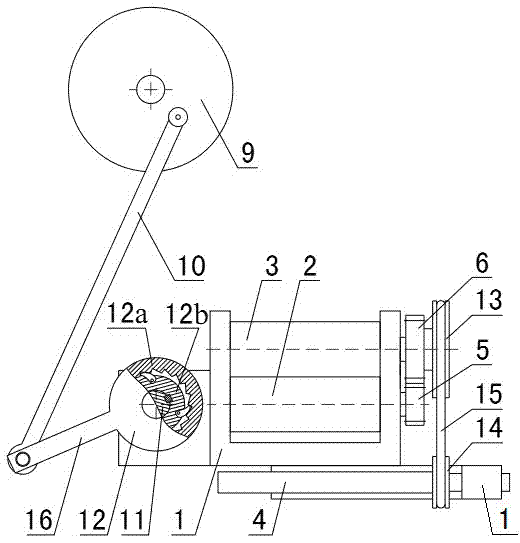

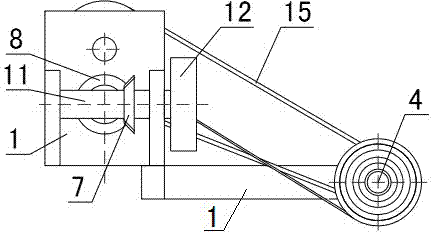

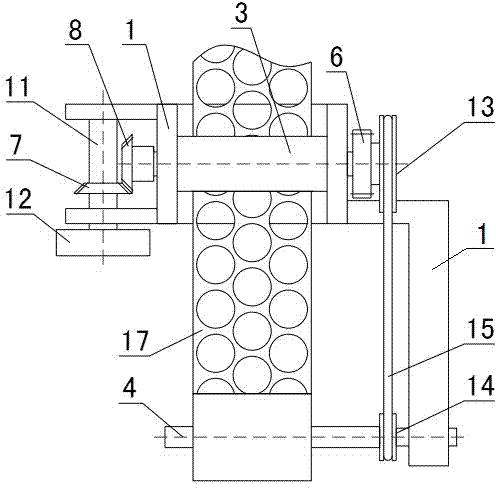

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

[0018] Such as figure 1 , figure 2 , image 3 The shown aluminum strip scrap winding mechanism includes a one-way intermittent drive mechanism, a base 1, a winding shaft 4, and driving and driven guide rollers 2 and 3, and the driving and driven guide rollers 2 and 3 are installed on the base in parallel up and down. On the seat 1, it can rotate around its axis relative to the base, and one end of the roller shaft of the driving guide roller 2 and the driven guide roller 3 is respectively fixed with a driving gear 5 and a driven gear 6 meshing with the driving gear 5. The other end of the roller shaft of the driving guide roller 2 is fixed with a driven bevel gear 8; the one-way intermittent drive mechanism includes a drive turntable 9, a connecting rod 10, an output shaft 11 and a ratchet assembly 12, and the output shaft 11 is installed on the base 1 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com