Energy-absorbing type front subframe

A front subframe and front section technology, which is applied in the field of energy-absorbing front subframe, can solve the problems of little contribution to collision safety, no energy-absorbing design, and inability to ensure the structural integrity of the passenger compartment, etc. The effect of occupant life safety, maintaining integrity, and preventing occupant living space from being damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

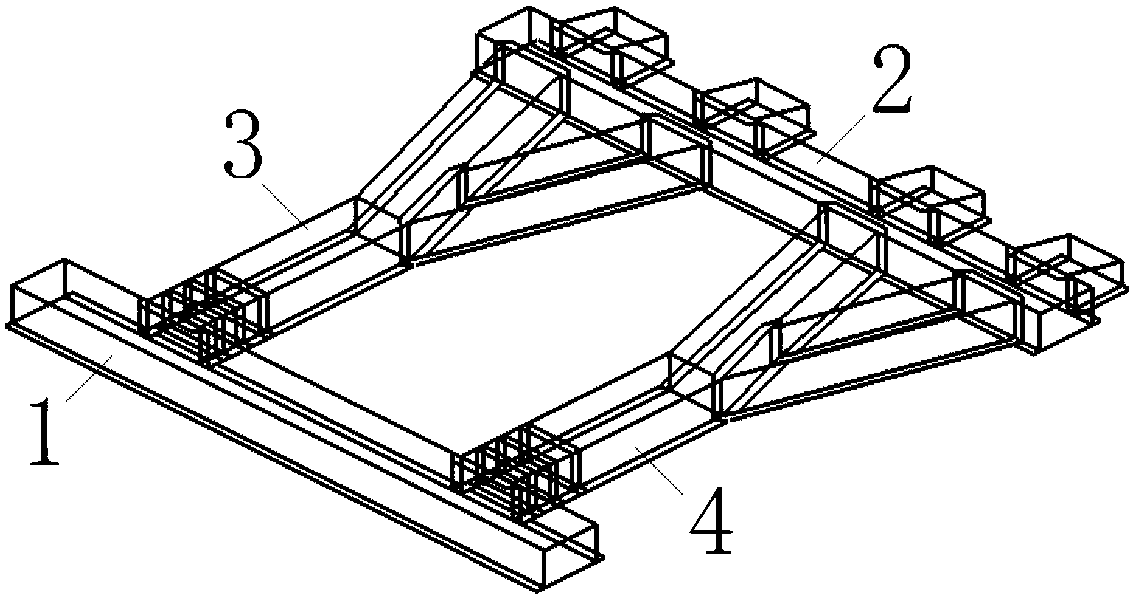

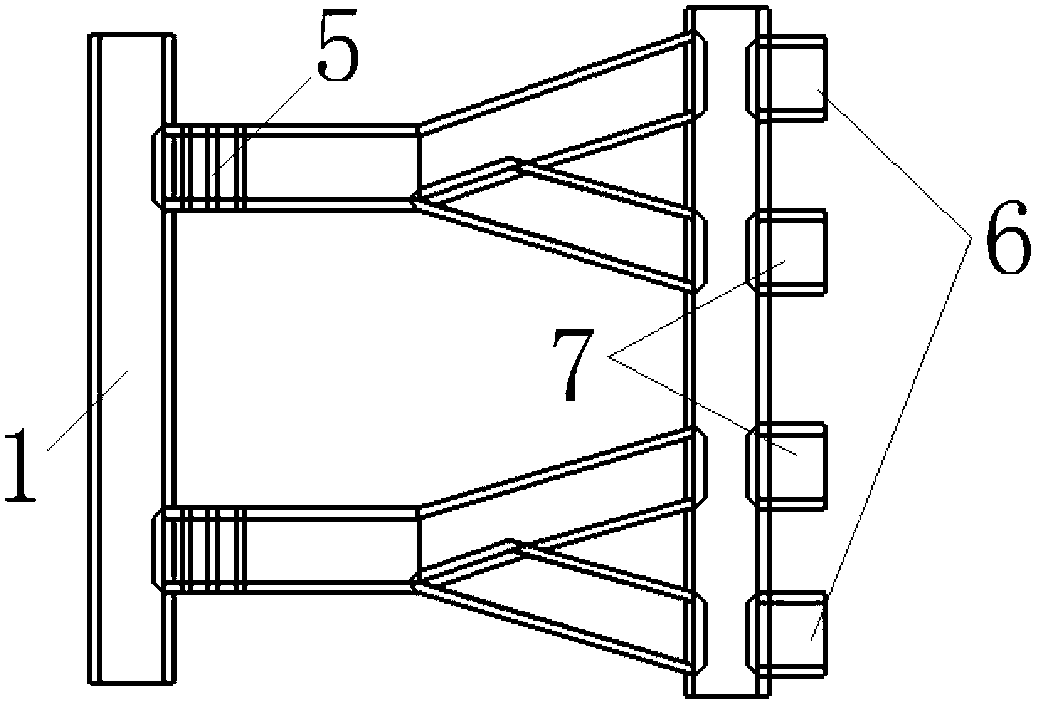

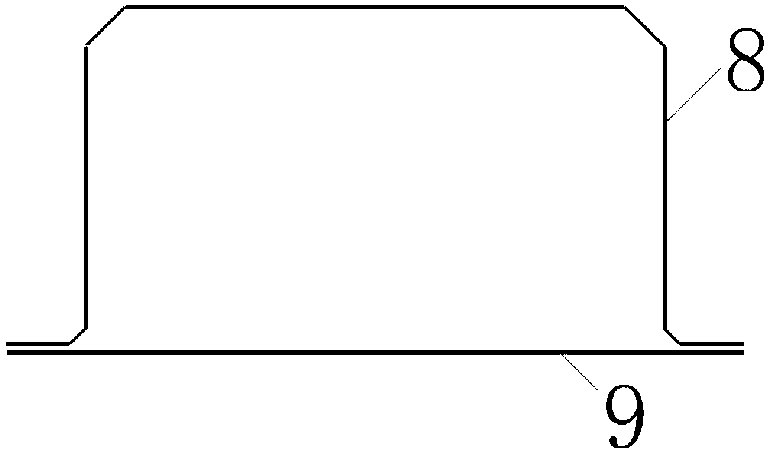

[0021] like Figure 1 to Figure 4 As shown, an energy-absorbing front sub-frame is a double "Y"-shaped frame-type front sub-frame. On the basis of not affecting the loading and installation requirements of the front sub- The front section of the longitudinal beam assembly on the left and right sides of the subframe is equipped with energy-absorbing grooves to fully absorb energy, and the rear section is designed with a bifurcated structure, which can transmit loads stably on the basis of ensuring the energy absorption of the front section.

[0022] The specific structure of the energy-absorbing front sub-frame is as follows: it includes the front beam assembly 1, the rear beam assembly 2, the right longitudinal beam assembly 3 and the left longitudinal beam assembly 4; among them, the right lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com