Device capable of reducing adhesion of volatile matters on window of reflecting screen of sapphire single crystal furnace

A sapphire single crystal furnace and viewing window technology, which is applied in the direction of single crystal growth, single crystal growth, post-processing equipment, etc., can solve the problems of narrowing of the viewing window, difficulty in cleaning, and reduction of observation range, etc., and achieves simple structure and easy installation. Easy to disassemble, easy to clean or replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

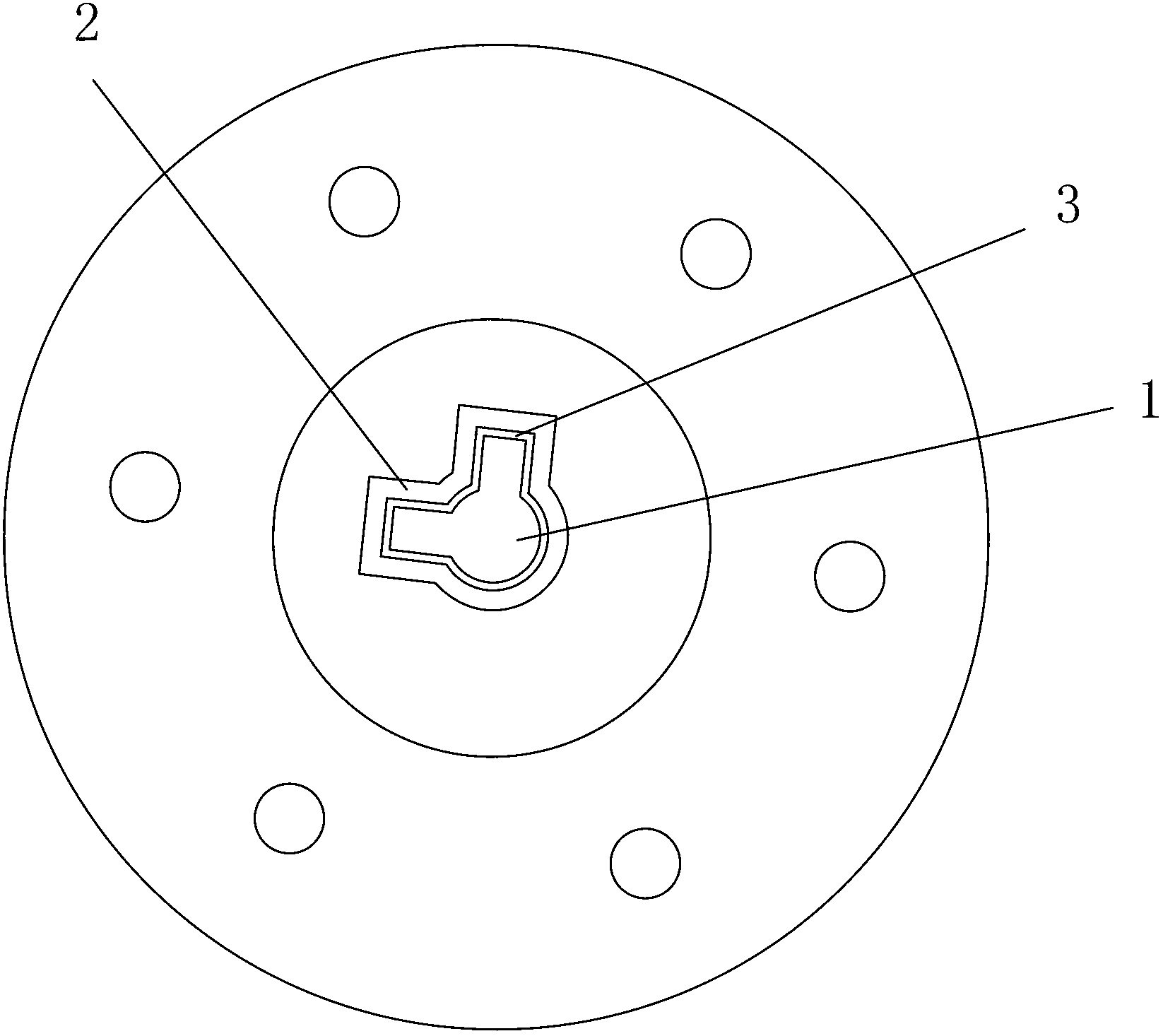

[0012] Such as figure 1 As shown, a device that can reduce the adhesion of volatiles on the viewing window of the sapphire single crystal furnace reflective screen includes being arranged in the viewing window 1 of the sapphire single crystal furnace reflective screen to prevent the volatiles from adhering to the viewing window 1 and The molybdenum tank body 2 that can be disassembled and cleaned is provided with a high temperature resistant self-cleaning non-stick coating layer 3 on the molybdenum tank body 2 .

[0013] The shape of the molybdenum tank body 2 in the present invention is the same as that of the viewing window 1 . The high-temperature-resistant self-cleaning non-stick coating layer 3 is ZS-522 high-temperature-resistant self-cleaning non-stick coating layer.

[0014] In the present invention, when the reflective screen i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com