Multifunctional hoisting support frame

A multi-functional, pole-tower technology, applied in the field of hoisting brackets, can solve the problems of complex and time-consuming installation of the new type of swallow-wing cross arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

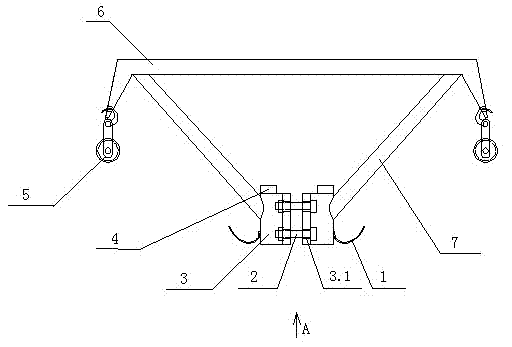

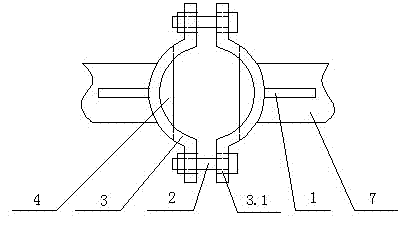

[0011] A multifunctional hoisting bracket installed on a power transmission line tower, which is composed of a horizontal beam 6 and two oblique rods 7 to form an approximately isosceles triangle frame, and the upper end of each oblique rod 7 is welded to the upper and lower ends of the horizontal beam 6 The hoop 3 is approximately semicircular, and the two ends of the hoop 3 are bent outwards to form an assembly part on which an assembly hole 3.1 is provided. Horizontal spacer plate 4 is installed above hoop 3. Hook 1 is installed on the outer surface of hoop 3, and fixed pulley 5 is installed respectively at the two ends of crossbeam 6. The height of hoop 3 is 200MM.

[0012] When the multifunctional hoisting bracket is installed on the tower, the limit plate 4 is just stuck on the top of the tower to ensure that the hoop 3 is always on the top of the tower.

[0013] When using the multi-functional hoisting bracket, an operator first climbs to the top of the tower, lifts t...

Embodiment 2

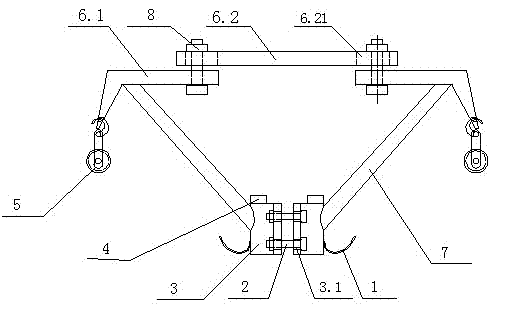

[0015] Since the beam in Embodiment 1 is a whole plate, when the space between the two hoops 3 does not completely coincide with the top of the tower, it will be very difficult to install the multifunctional hoisting bracket and tighten the first bolt 2. Can't even install. Therefore, Example 2 is proposed. It differs from Embodiment 1 in that the crossbeam 6 is changed into a telescopic structure, that is, the crossbeam 6 is composed of a middle crossbeam 6.2 and two side crossbeams 6.1. There are two rectangular holes 6.21 on the middle beam 6.2, and a through hole on the side beam 6.1. The middle beam 6.2 overlaps with the two side beams 6.1, and the second bolt 8 passes through the rectangular holes 6.21 and the two side beams 6.2. The through holes on the side beams 6.1 connect the middle beam 6.2 and the side beams 6.1 into one body. Between middle crossbeam 6.2 and two side crossbeams 6.1, can move relatively along rectangular hole 6.21, the length of promptly crossbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com