Pipeline built-in sealing device

A sealing device and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of complex construction, high construction cost, waste of materials, etc., to reduce construction cost, good sealing effect, loading and unloading handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

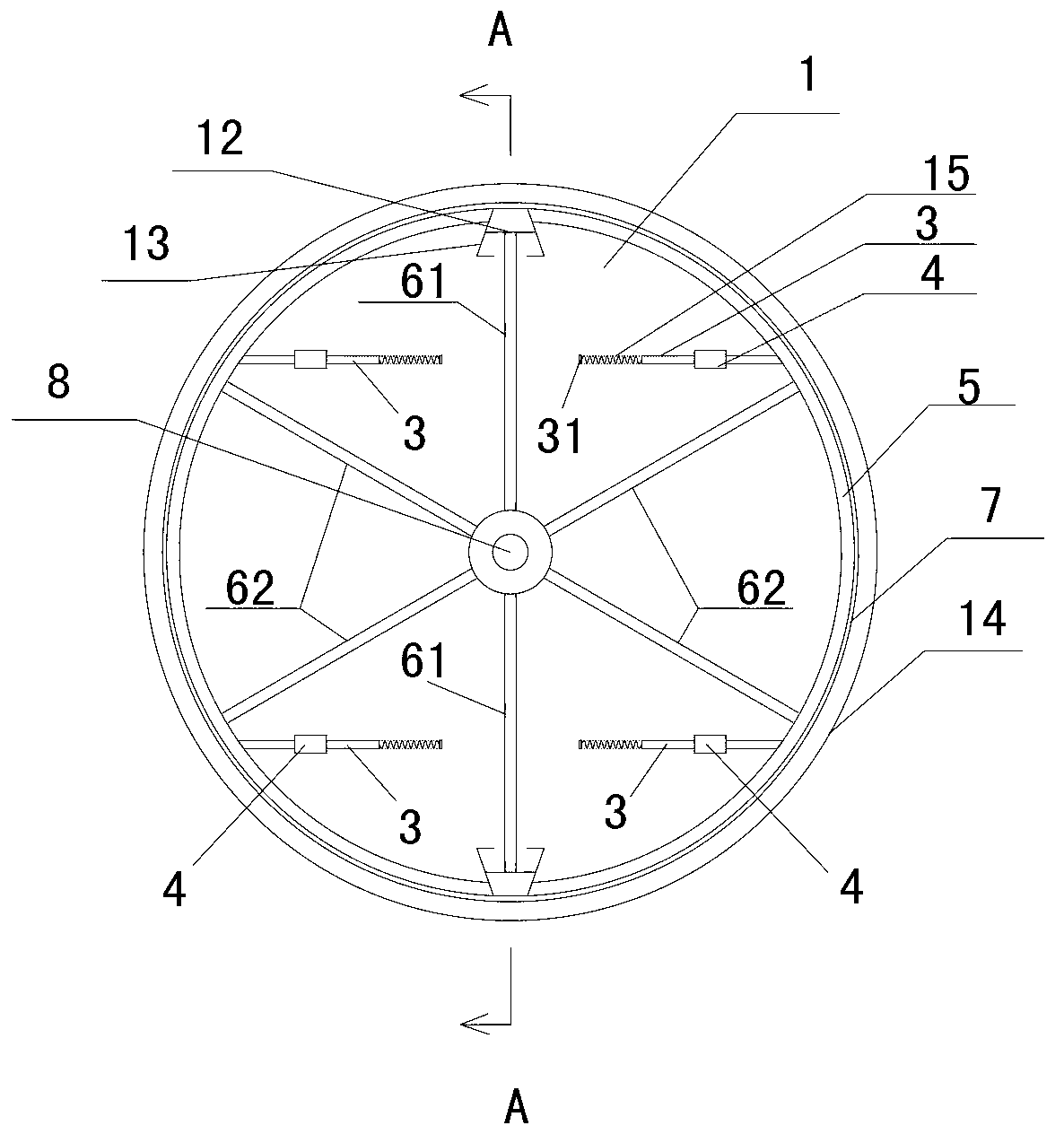

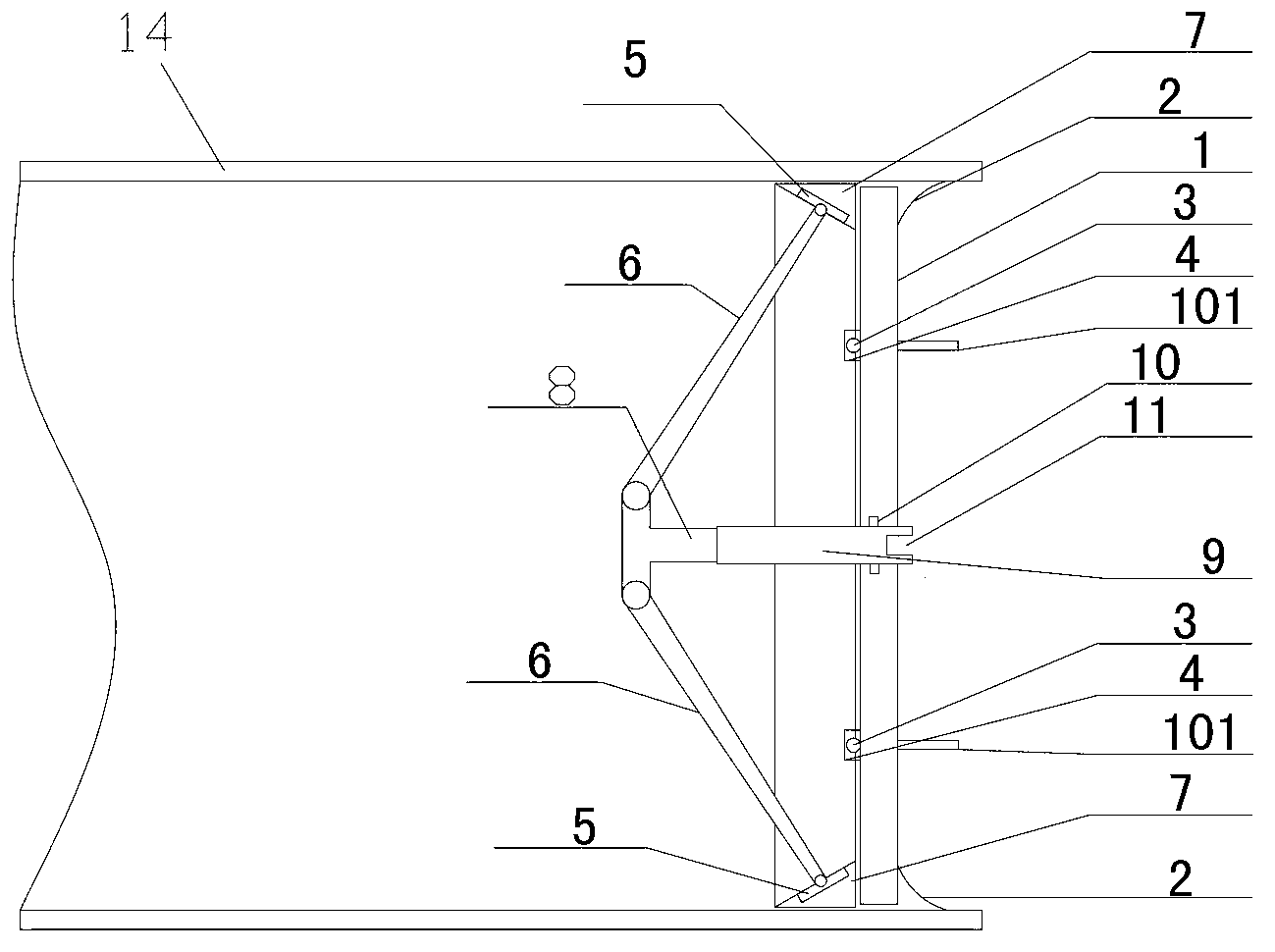

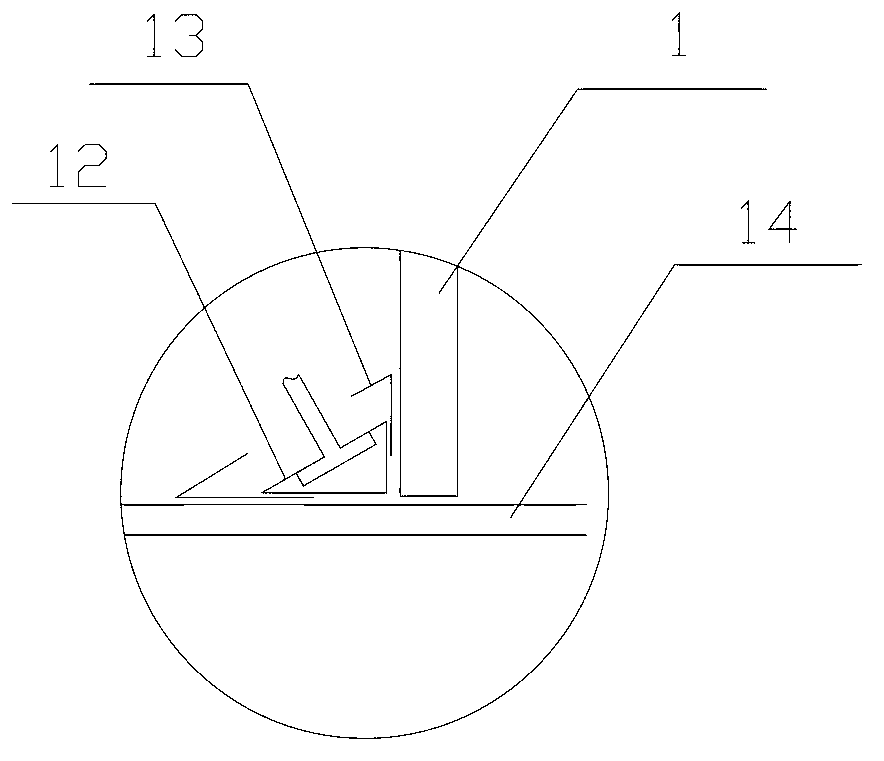

[0030] like figure 1 and figure 2 As shown, the pipeline built-in sealing device of the present invention includes a sealing plate 1, whose diameter is slightly smaller than that of the laid pipeline, and has a hole in the center, and a rolling bearing 10 is arranged in the hole, and the internal thread sleeve 9 is installed through the rolling bearing 10. On the blocking plate 1; one end of the internally threaded sleeve 9 is provided with a rotating device. In this embodiment, the rotating device is preferably an inner hexagonal head 11, which can prevent theft. The other end of the internally threaded sleeve 9 is mated with one end of the externally threaded center rod 8 , and when the internally threaded sleeve 9 rotates, the externally threaded central rod 8 can move in the internally threaded sleeve 9 along its axial direction. The other end of external thread central rod 8 is hinged with one end of connecting rod II62.

[0031] One end of the connecting rod II62 is h...

Embodiment 2

[0036] like figure 1 and figure 2 As shown, the pipeline built-in sealing device of the present invention includes a sealing plate 1, whose diameter is slightly smaller than that of the laid pipeline, and has a hole in the center, and a rolling bearing 10 is arranged in the hole, and the internal thread sleeve 9 is installed through the rolling bearing 10. On the blocking plate 1; one end of the internally threaded sleeve 9 is provided with a rotating device. In this embodiment, the rotating device is preferably an inner hexagonal head 11, which can prevent theft. The other end of the internally threaded sleeve 9 is mated with one end of the externally threaded center rod 8 , and when the internally threaded sleeve 9 rotates, the externally threaded central rod 8 can move in the internally threaded sleeve 9 along its axial direction. The other end of external thread central rod 8 is hinged with one end of connecting rod II62.

[0037] One end of the connecting rod II62 is h...

Embodiment 3

[0043] Such as figure 1 with figure 2 As shown, the pipeline built-in sealing device of the present invention includes a sealing plate 1, whose diameter is slightly smaller than that of the laid pipeline, and has a hole in the center, and a rolling bearing 10 is arranged in the hole, and the internal thread sleeve 9 is installed through the rolling bearing 10. On the blocking plate 1; one end of the internally threaded sleeve 9 is provided with a rotating device. In this embodiment, the rotating device is preferably an inner hexagonal head 11, which can prevent theft. The other end of the internally threaded sleeve 9 is mated with one end of the externally threaded center rod 8 , and when the internally threaded sleeve 9 rotates, the externally threaded central rod 8 can move in the internally threaded sleeve 9 along its axial direction. The other end of external thread central rod 8 is hinged with one end of connecting rod II62.

[0044] One end of the connecting rod II62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com