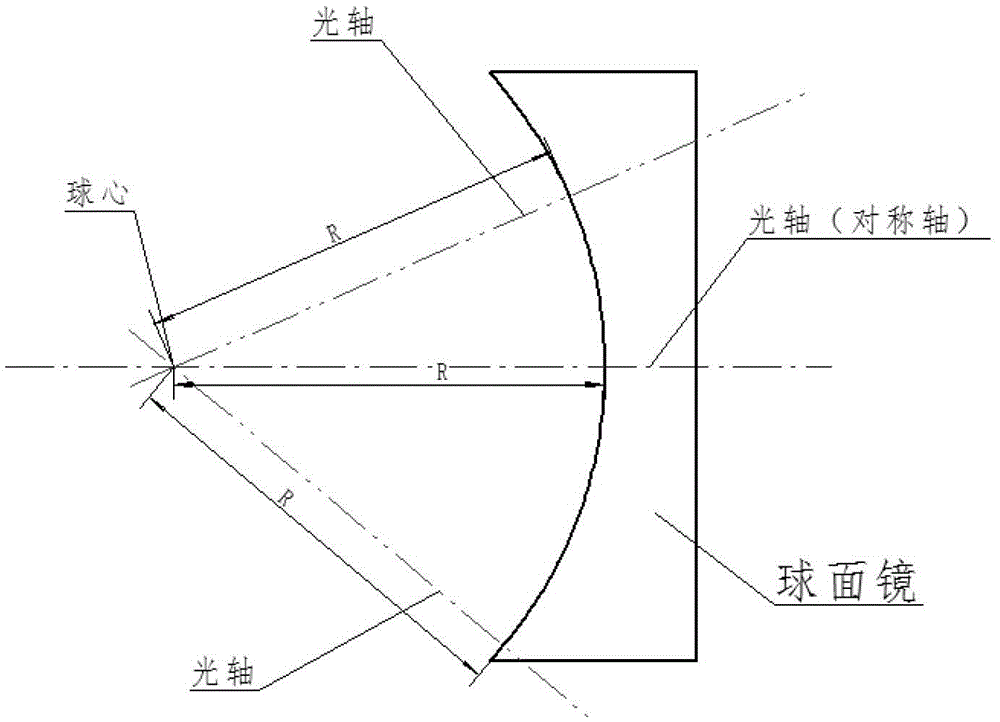

Method and device for measuring vertex radius of off-axis optical aspheric mirror

An off-axis aspheric and aspheric mirror technology, applied in the field of optical detection, can solve the problems of low accuracy of measurement methods, inaccurate measurement of vertex radius, scratches on the mirror surface, etc., and achieves the effects of convenient calculation, reduction of measurement errors, and improvement of precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

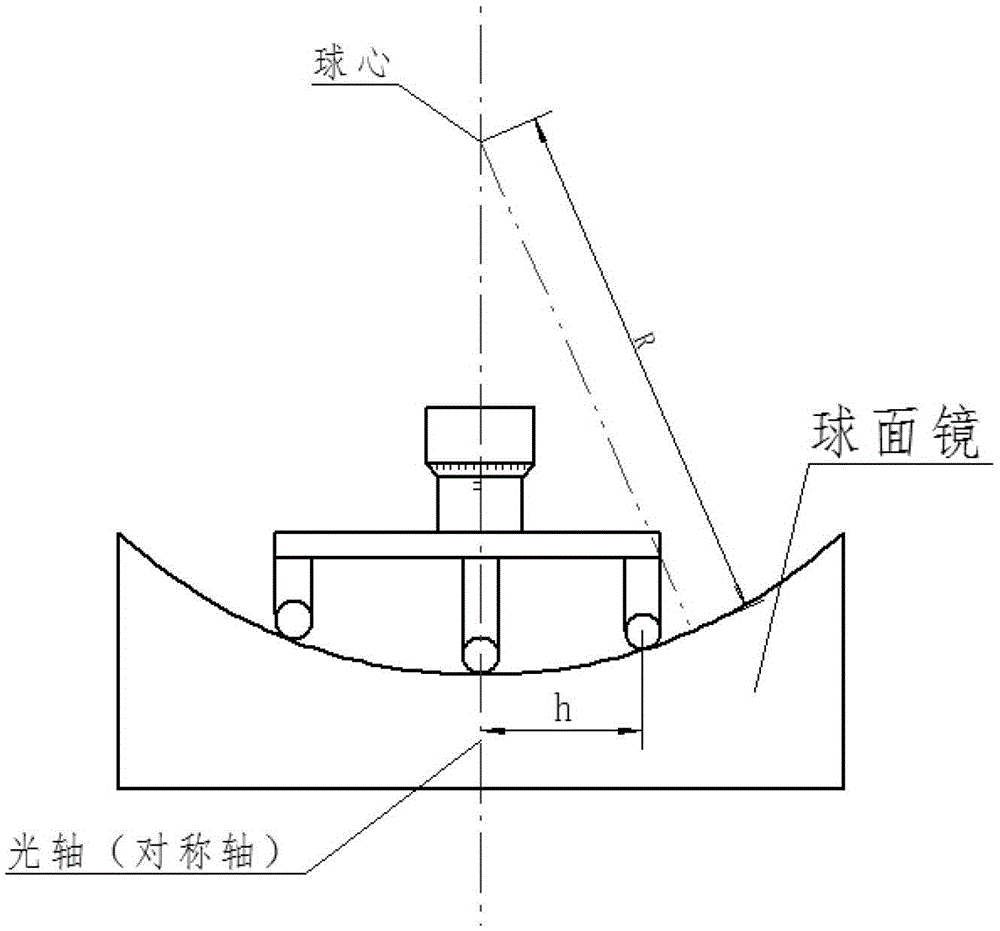

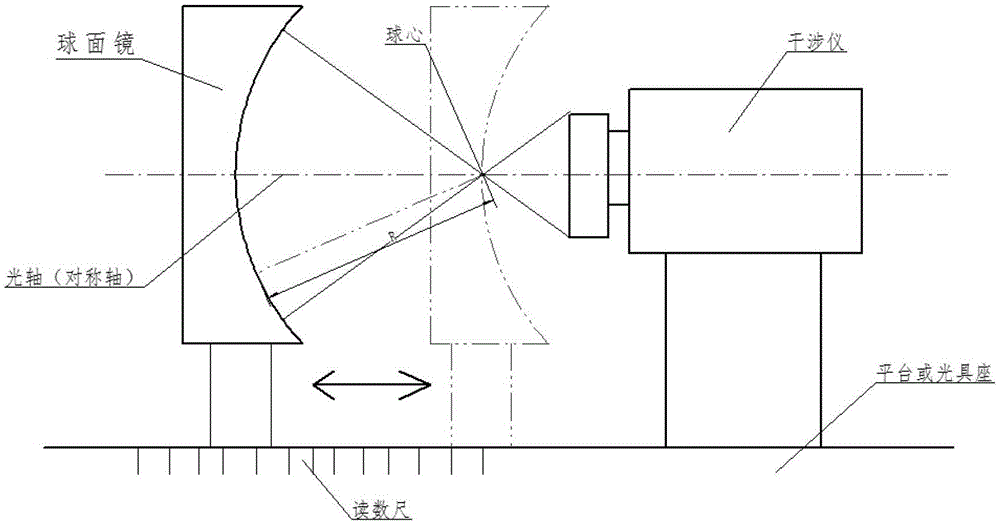

[0037] Invention idea of the present invention is:

[0038] The present invention uses the off-axis aspheric surface detection compensator to determine the optical axis of the off-axis aspheric mirror, and according to the different characteristics of the intersection point of the normal line and the optical axis at different points on the off-axis aspheric surface, the optical axis determined by the aspheric surface detection compensator is fixed. On the tooling, install the thin beam transmitter and receiver, combine the light reflection law, use the encoder to measure the angle between the transmitter, the receiver and the optical axis, and measure the axial distance between the transmitter and the receiver, and calculate the distance between the beam and the optical axis. The angle between the normal line and the optical axis of the intersection point of the aspheric surface is combined with the law of thin beam mirrors to measure the angle between the normal line at any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com