PM1 (Particulate Matter) jointed multi-level cutting sampling head

A sampling head and conjoined technology, which is applied in the field of PM1 conjoined multi-stage cutting sampling head, can solve the problems of inability to achieve graded collection of particulate matter, small size, limited range, etc., and achieve safety and aesthetics, cutting particle size Accurate, collection efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

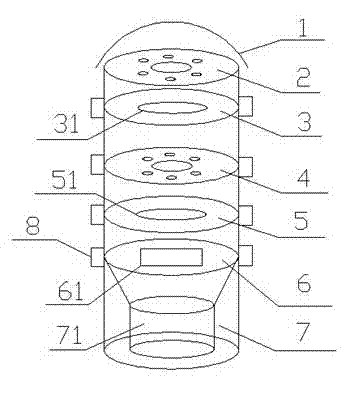

[0035] Such as Figure 1-Figure 4 As shown, a PM1 conjoined multi-stage cutting sampling head, the PM1 conjoined multi-stage cutting sampling head is a layered combination structure, mainly composed of cutting mouth cover 1, PM2.5 impact nozzle layer 2, PM2 from top to bottom .5 impact plate layer 3, PM1 impact nozzle layer 4, PM1 impact plate layer 5, filter membrane collection layer 6, PUF collection layer composition 7,

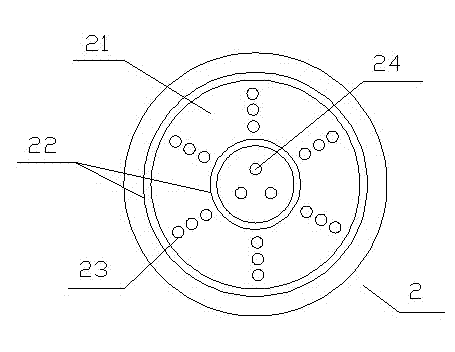

[0036] The PM2.5 impact nozzle layer 2 and the PM1 impact nozzle layer 4 both include an impact nozzle plate and at least one group of impact nozzles 23 arranged in an equidistant circular arrangement on different diameters on the impact nozzle plate;

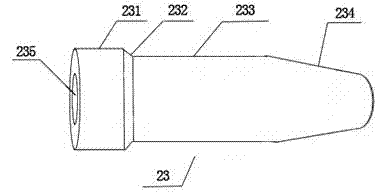

[0037] The upper end of the impact nozzle 23 is a first cylinder 231; the middle part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com