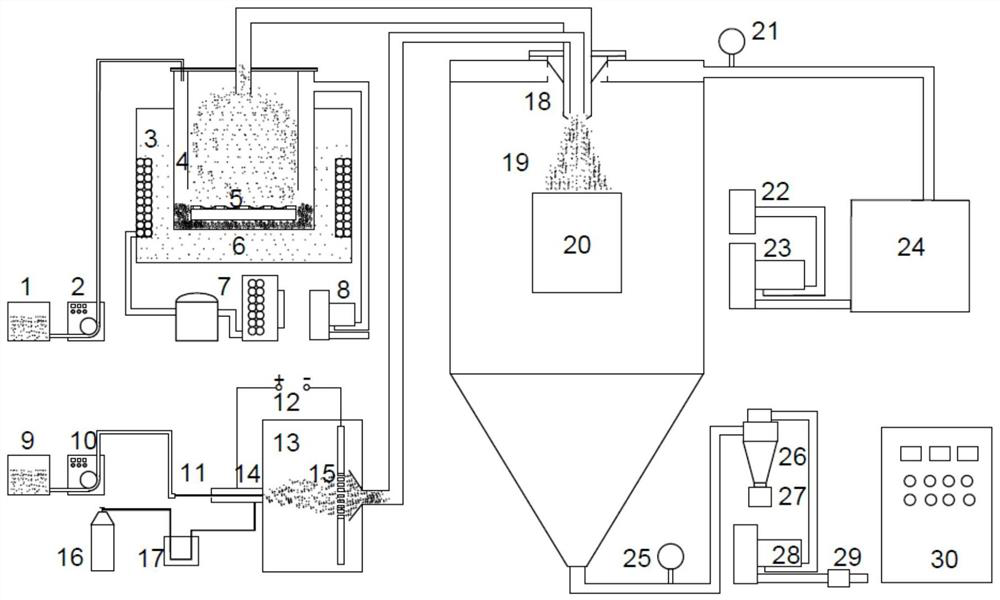

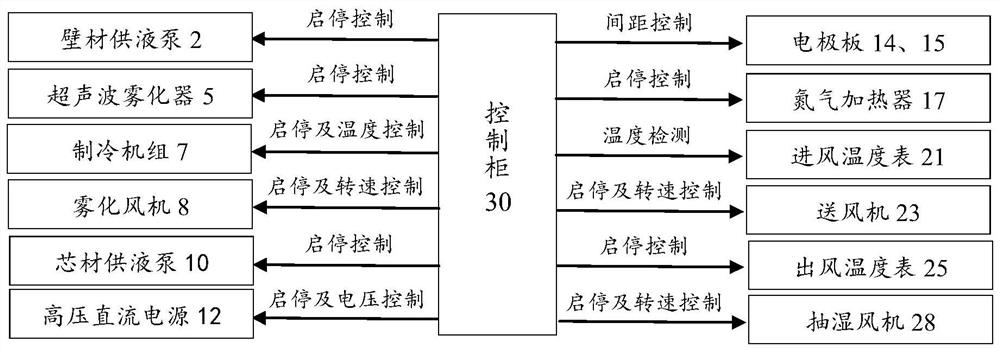

A drying device for electrospray ionization coupled with ultrasonic atomization and method for preparing microcapsules

A technology of electrospray ionization and drying device, which is used in microcapsule preparation, spray evaporation, microsphere preparation and other directions to achieve the effect of reducing production energy consumption, reducing addition amount, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0048] Example 2, the method for preparing vitamin C microcapsules by electrospray ionization coupling ultrasonic atomization

[0049] Prepare 500mL, 5% mass fraction of vitamin C aqueous solution and 2000mL, 0.2% mass fraction of sodium alginate aqueous solution respectively. 0.5% ethanol was added to the aqueous solution of sodium alginate to improve the atomization efficiency. Then slowly add 1M HCL / NaOH respectively to adjust the pH of the core material and wall material solutions to 7.0±0.2. After fully dissolving and mixing at room temperature (25±3°C), put the sodium alginate aqueous solution into the wall material liquid container 1, and put the vitamin C aqueous solution into the core material liquid container 9. All the sample solutions configured above should be used up on the same day, and the remaining samples can be temporarily stored at 4°C for 1-5 days after adding 0.05% NaCN by mass fraction.

[0050] When preparing the microcapsules, turn on the wall materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com