Method for enriching and recovering zinc-rich dust in zinc-containing gas

A technology for coal gas and dust, applied in the field of enrichment and recovery of zinc-rich dust in zinc-containing gas, can solve the problems of low dust collection efficiency, inability to provide reliable guarantee for precise dust removal and enrichment of zinc-containing dust, and achieve stable operation, collection, The effect of high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

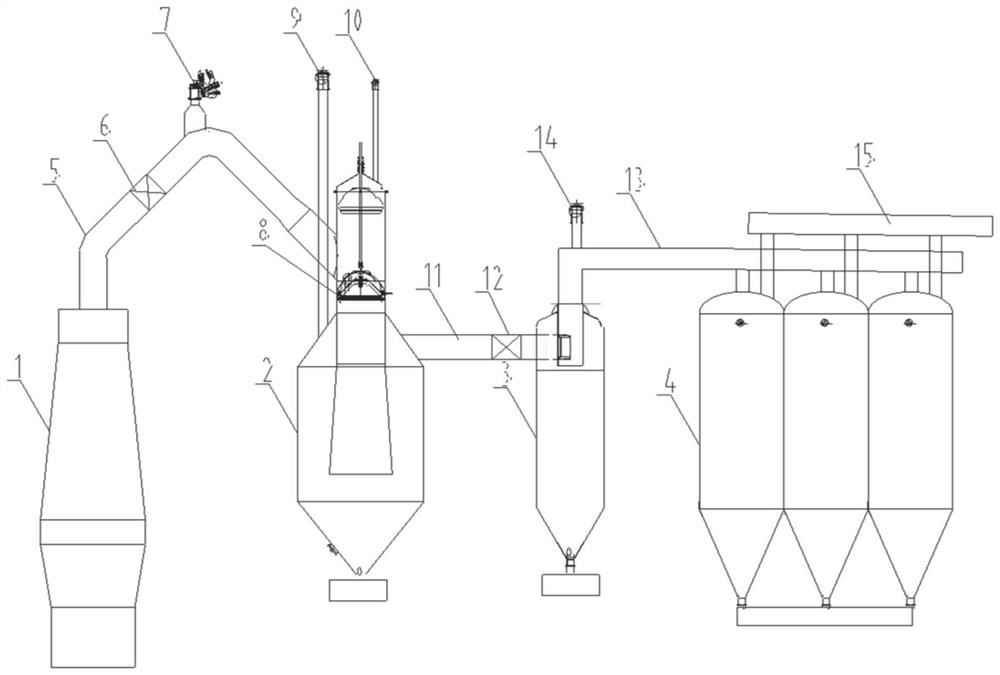

[0094] The present embodiment provides a dust removal system for enriching and recovering zinc-rich dust in zinc-containing gas, the schematic diagram of which is as follows: figure 1 shown, from figure 1 It can be seen that the system includes:

[0095]Solid waste treatment furnace 1, primary coarse dust removal device 2, secondary dust removal device 3 and fine dust removal device 4, the gas outlet of the solid waste treatment furnace 1 is communicated with the inlet of the primary coarse dust removal device 2 through a gas outlet pipe 5, The gas outlet at the upper part of the side wall of the primary coarse dust removal device 2 is communicated with the inlet of the secondary dust removal device 3 through the gas pipeline 11, and the gas outlet at the top of the secondary dust removal device 3 passes through the semi-clean gas The pipeline 13 is communicated with the inlet of the fine dust removal device 4 at the top thereof, and the gas outlet of the fine dust removal de...

Embodiment 2

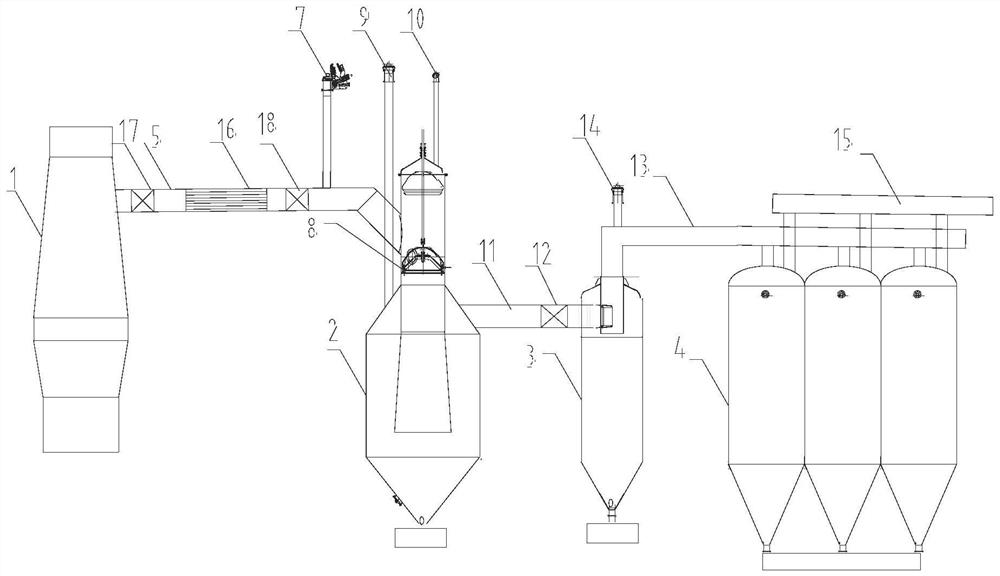

[0107] The present embodiment provides a dust removal system for enriching and recovering zinc-rich dust in zinc-containing gas, the schematic diagram of which is as follows: figure 2 shown, from figure 2 It can be seen that the system includes:

[0108] Solid waste treatment furnace 1, primary coarse dust removal device 2, secondary dust removal device 3 and fine dust removal device 4, the gas outlet of the solid waste treatment furnace 1 is communicated with the inlet of the primary coarse dust removal device 2 through a gas outlet pipe 5, The gas outlet at the upper part of the side wall of the primary coarse dust removal device 2 is communicated with the inlet of the secondary dust removal device 3 through the gas pipeline 11, and the gas outlet at the top of the secondary dust removal device 3 passes through the semi-clean gas The pipeline 13 is communicated with the inlet of the fine dust removal device 4 at the top thereof, and the gas outlet of the fine dust removal...

Embodiment 3

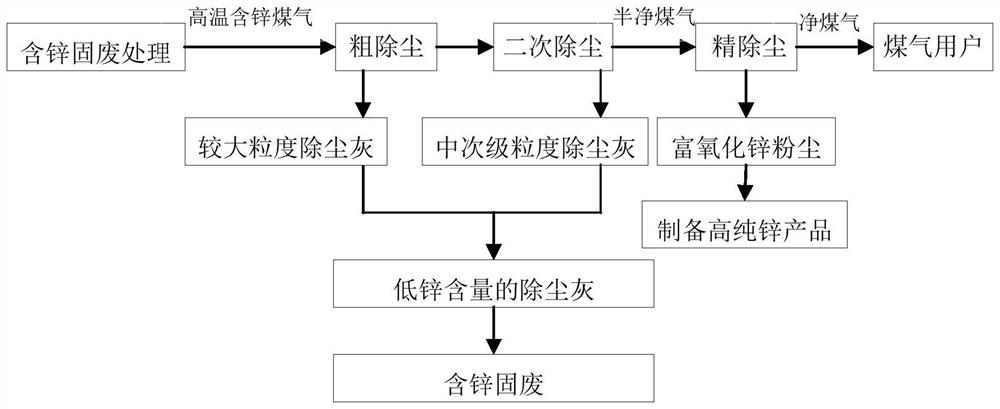

[0121] This embodiment provides a method for enriching and recovering zinc-rich dust in zinc-containing gas, which is realized by using the dust removal system for enriching and recovering zinc-rich dust in zinc-containing gas provided in Example 2. The specific process flow diagram of the method is like image 3 shown, from image 3 It can be seen that it includes the following specific steps:

[0122] (1) Make the zinc-containing solid waste enter the solid waste treatment furnace through the feeding system, and reduce and extract the zinc in the zinc-containing solid waste in the solid waste treatment furnace, so that the reduced zinc enters the high-temperature zinc-containing gas;

[0123] Wherein, the zinc-containing solid waste includes zinc-containing blocks obtained after being processed by hot agglomeration process and cold-solid pelletizing process, such as sintered ash, blast furnace ash, converter ash, electric furnace ash, etc. of iron and steel plants, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com