High-efficiency and pollution-free spray-suction underwater sediment classification collection device

A technology for collecting device and sediment, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., which can solve the problem of expensive equipment, high energy consumption, pollution of surrounding environment and underwater environment and other issues to achieve the effect of ensuring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

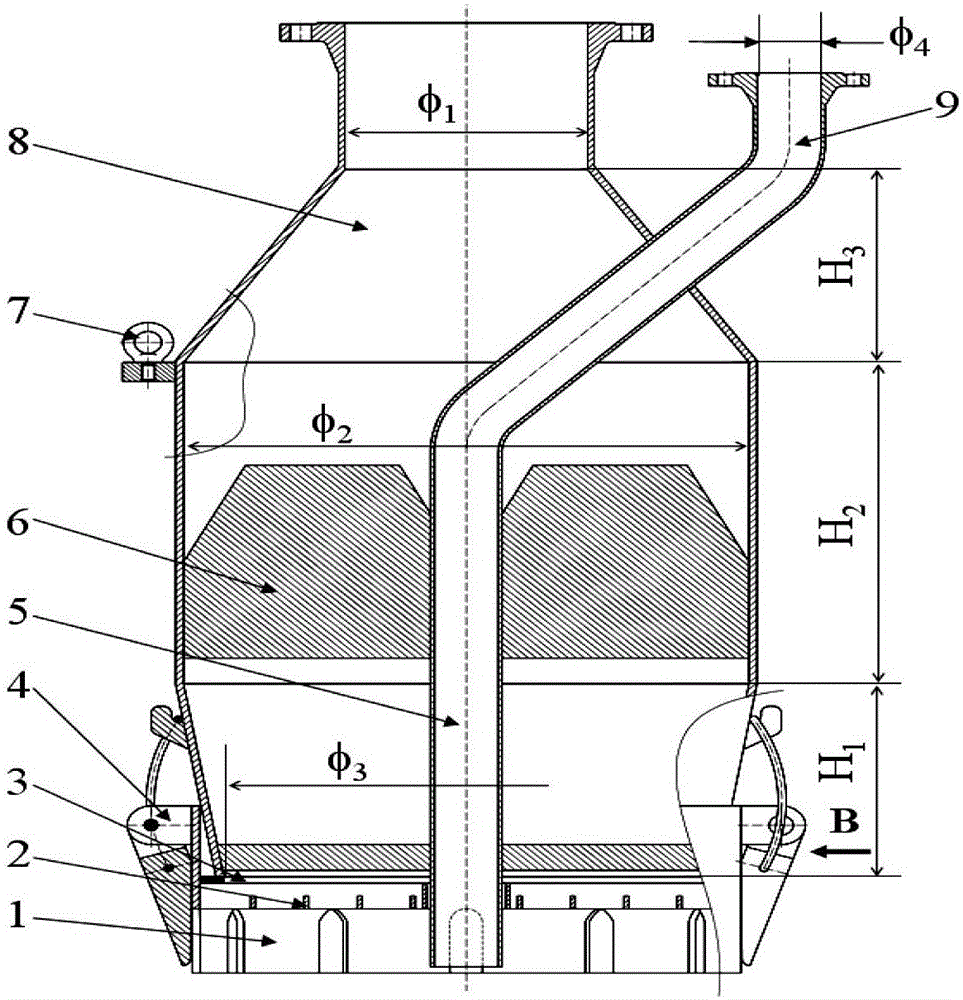

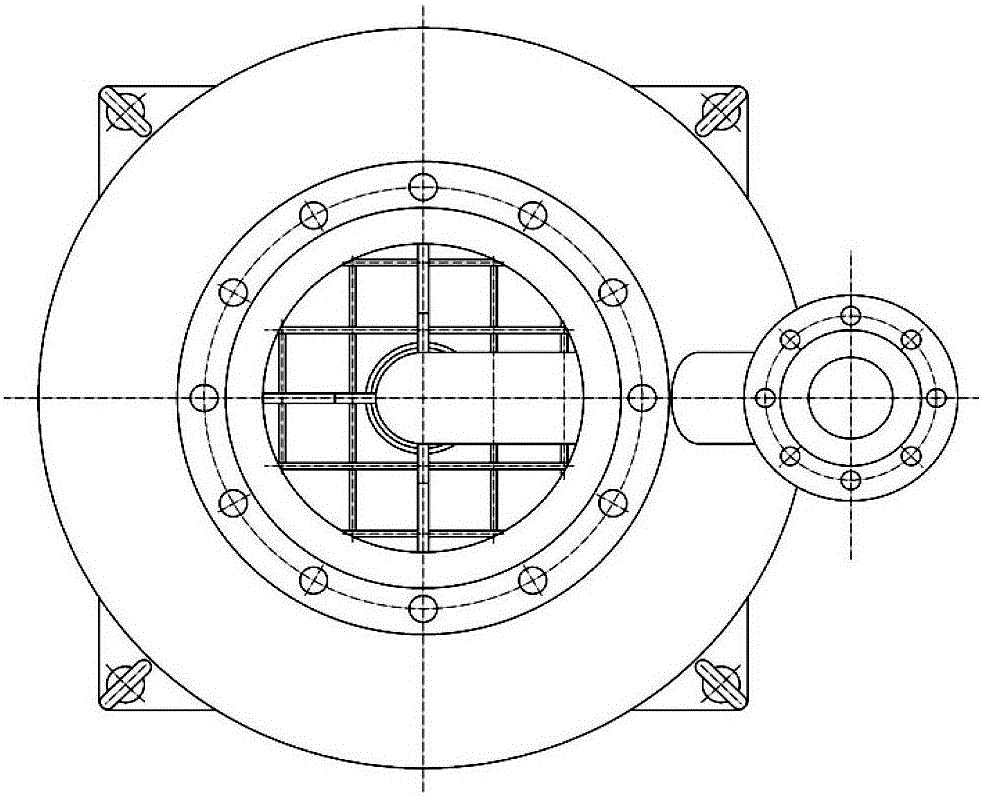

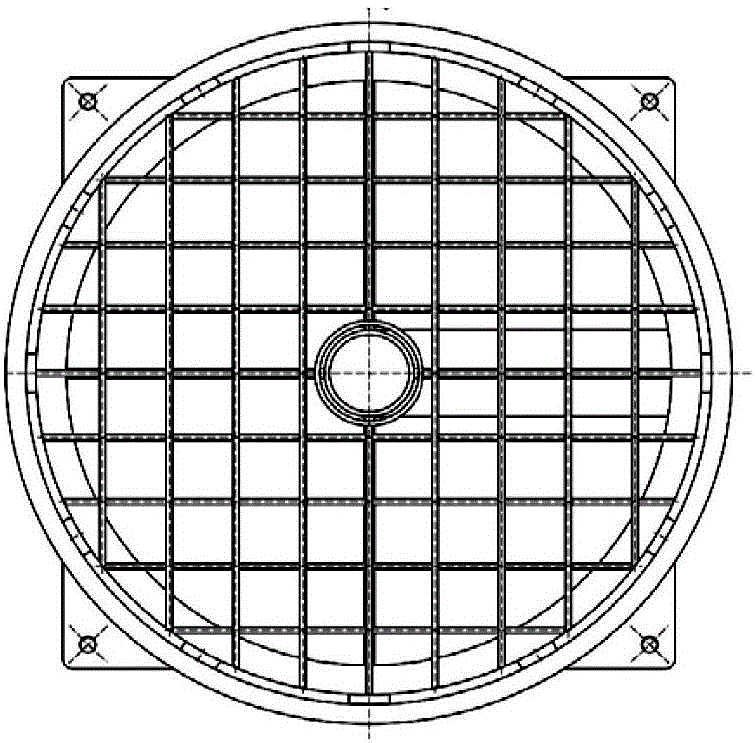

[0024] figure 1 It is a front sectional view of the acquisition device structure of the present invention, figure 2 for figure 1 top view of image 3 It is a partial cross-sectional view of the acquisition device structure of the present invention, Figure 4 for figure 1 B direction partial view, Figure 5 It is a schematic diagram of the sediment classification collection process of the present invention.

[0025] figure 1 Among them, 1 is the sand suction port, where sediment particles of different particle sizes enter the collector; 2 is the suction grille cover, which is used to filter out non-sediment substances with large area and light specific gravity, such as plastic cloth; 3 is a rubber gasket, which is used to realize the mutual sealing between the suction grille cover and the lower opening of the suction cavity; 4 is a quick buckle, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com