Automatic warehouse audit system

An automatic and warehouse technology, applied in the field of warehouse management systems, can solve problems such as low efficiency, large manpower consumption, and missing items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

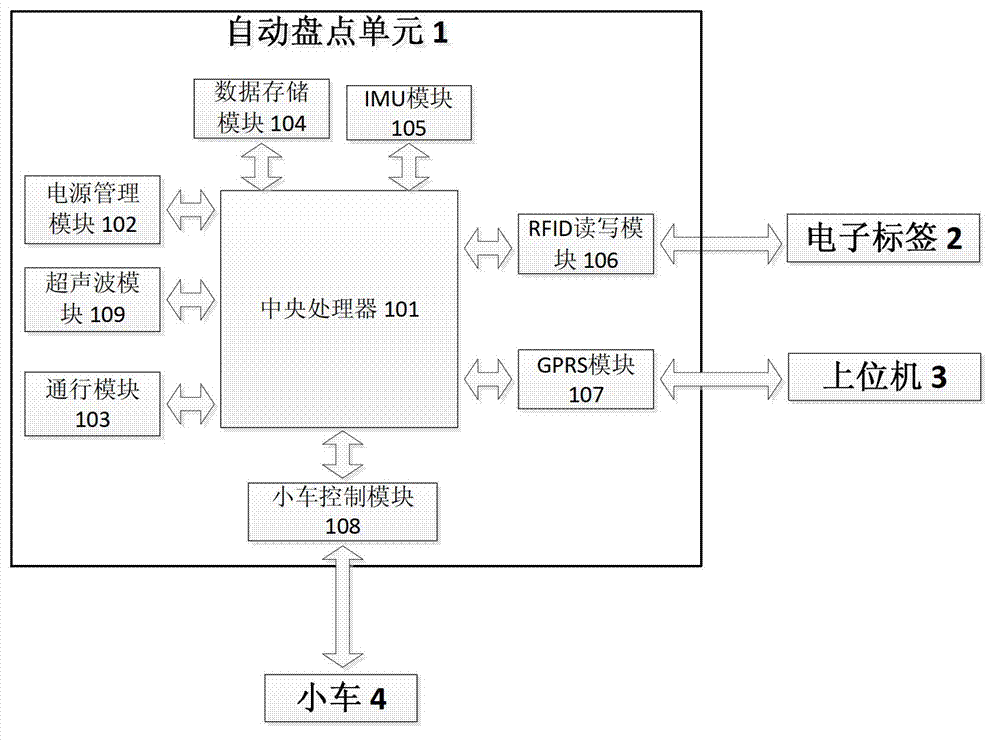

[0019] like figure 2 As shown, a warehouse automatic inventory system includes an automatic inventory unit 1, an electronic label 2, a host computer 3, a trolley 4 and a reference label carrying position information. The automatic inventory unit 1 is located on the trolley 4 and includes a central processing Device 101 and power management module 102, communication module 103, data storage module 104, ultrasonic module 109, IMU module 105, RFID read-write module 106, GPRS module 107 and car control module 108 respectively connected with central processing unit 101, car control The module 108 is connected to the trolley 4, and the reference tag is placed on the aisle of the warehouse.

[0020] The electronic label 2 is attached to the outside of the goods package and faces the warehouse aisle.

[0021] The GPRS module 107 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com