Calibrating method for two-dimensional laser and camera without overlapped viewing fields

A two-dimensional laser and calibration method technology, applied in image data processing, instruments, calculations, etc., can solve problems such as low precision, limited placement of cameras and laser scanners, and high cost of manual selection, etc., to achieve high Calibration accuracy, large field of view, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the drawings.

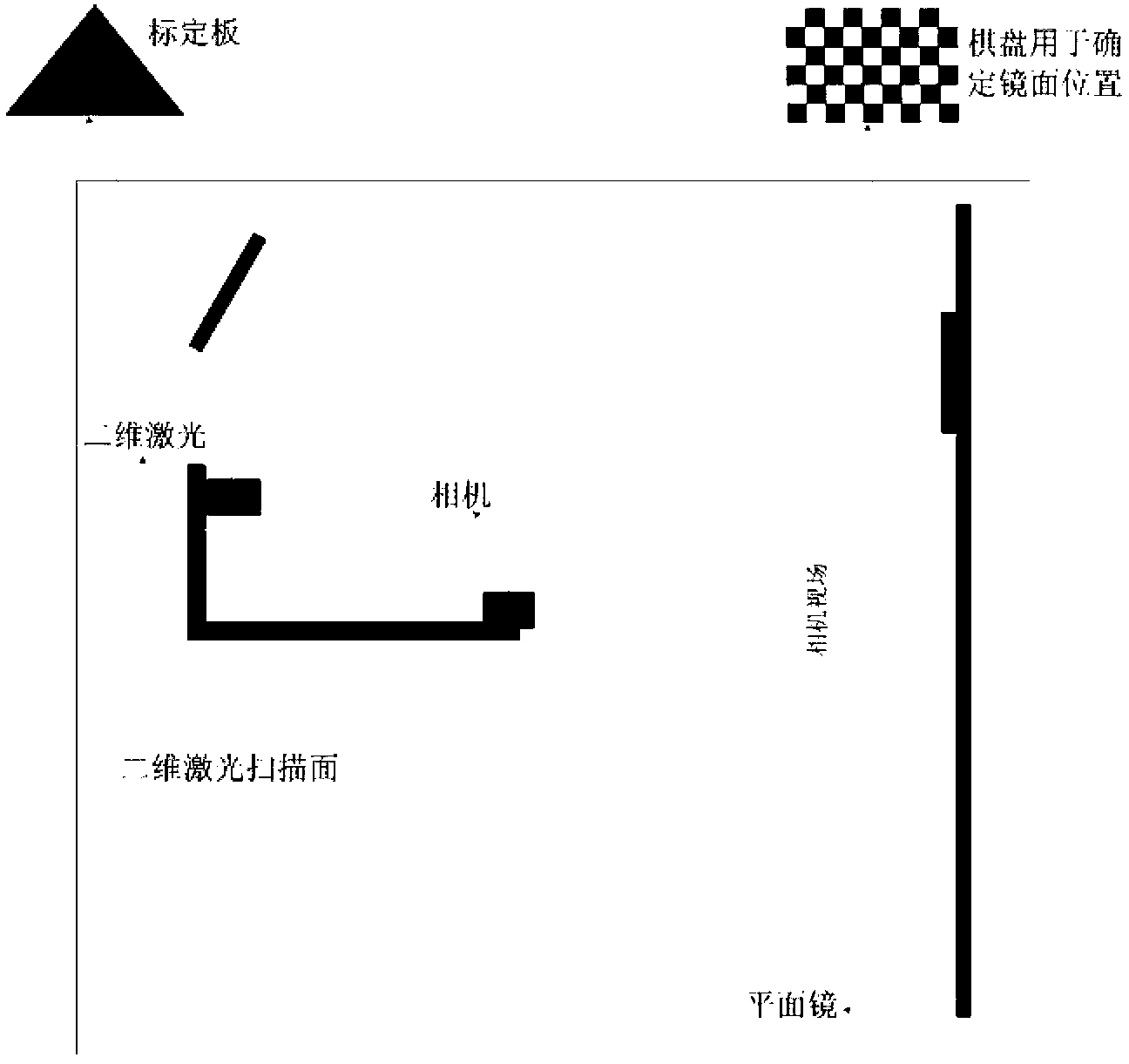

[0032] Such as figure 1 Shown is the composition diagram of the camera and two-dimensional laser calibration system of the present invention. The system mainly includes: two-dimensional laser scanner, camera, plane mirror, etc.

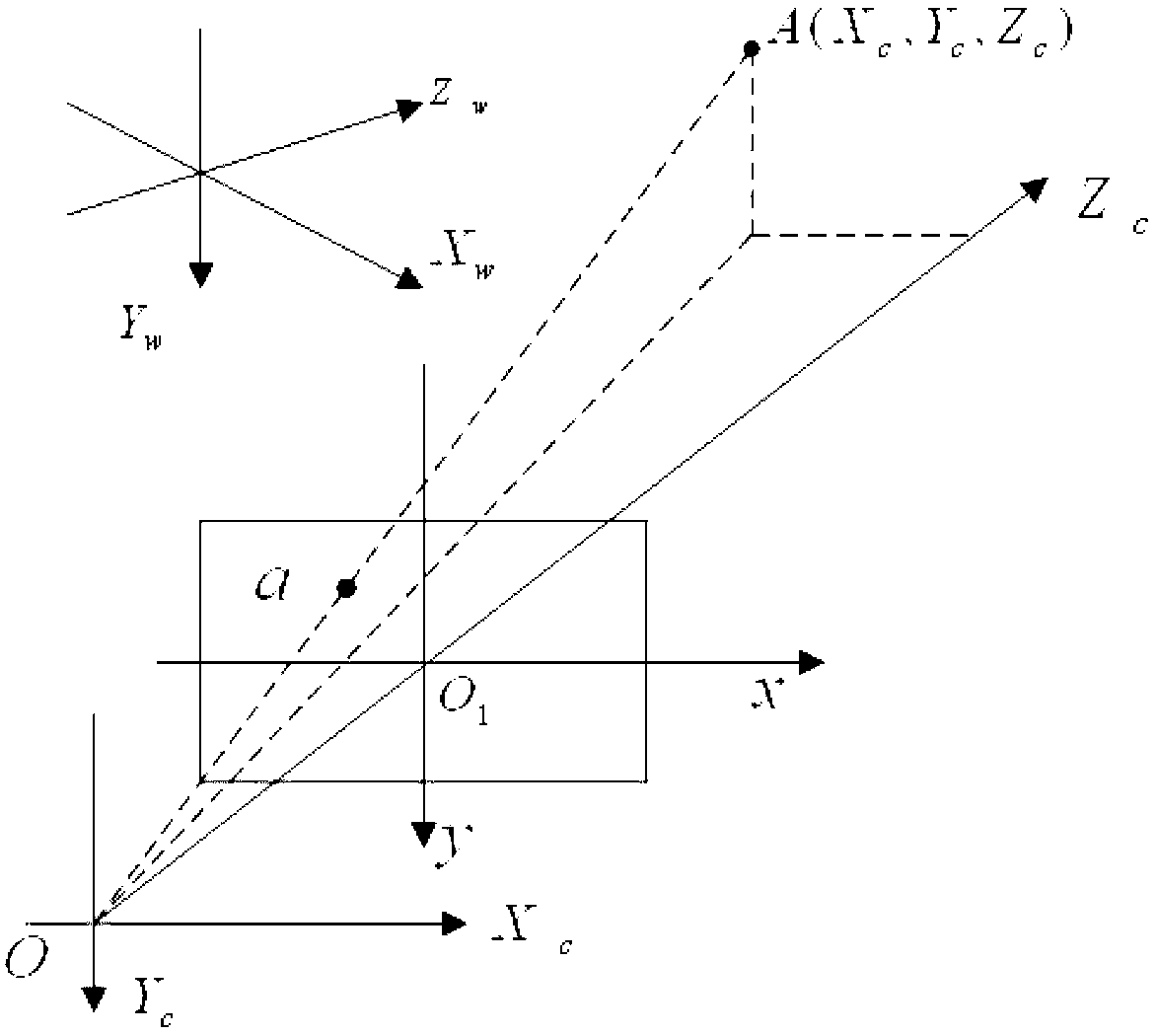

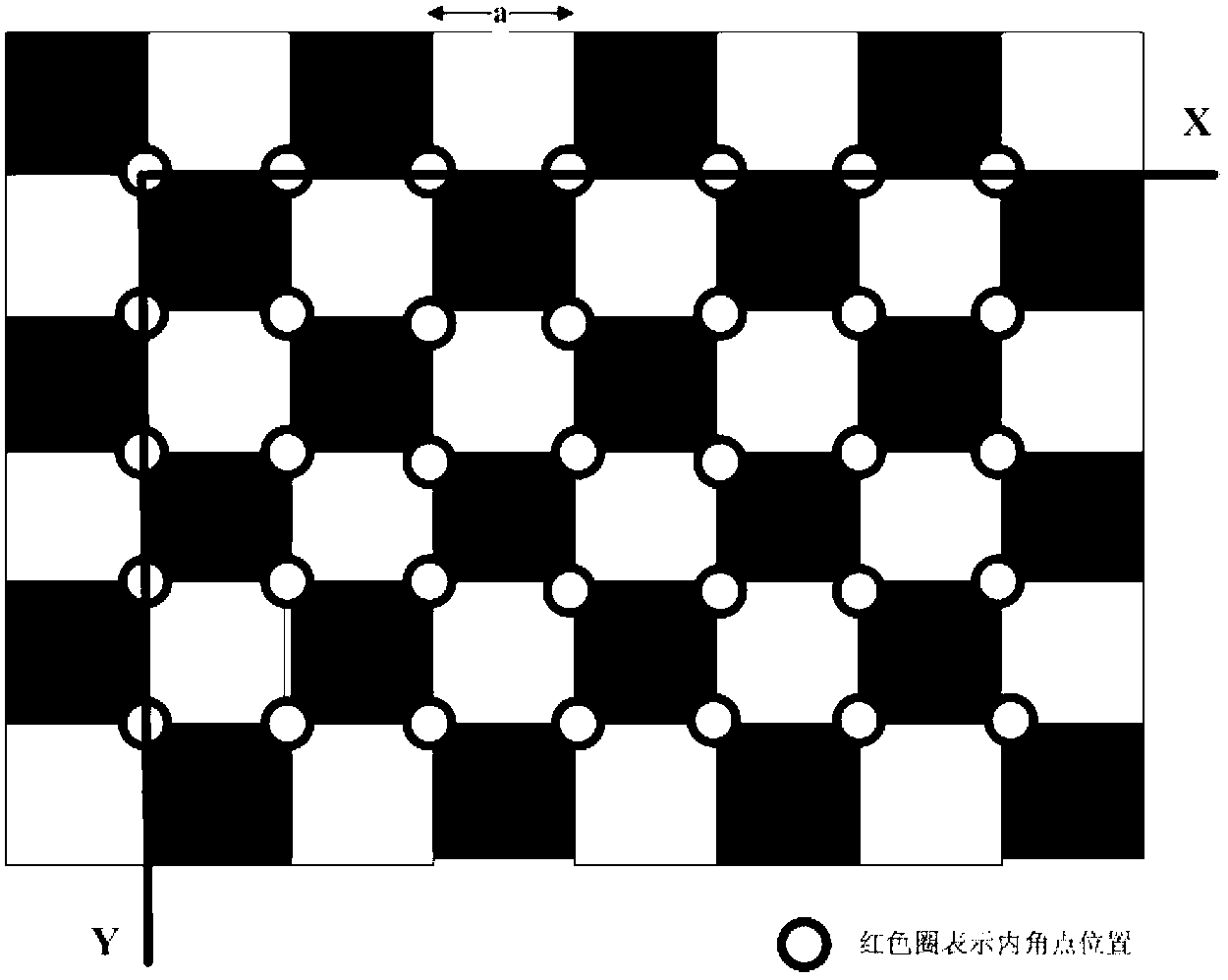

[0033] Step 1: Use the pinhole camera model to consider the lens distortion factor, and use the traditional checkerboard table to calibrate the camera's internal parameters. In the image plane, the upper left corner is the coordinate origin, the horizontal direction is the u axis, the vertical direction is the v axis, and the unit is pixel. Since the rectangular coordinate system uv only represents the number of rows and columns of pixels in the digital image, However, the position of the pixel in the image is not expressed in physical units, and a coordinate system xy expressed in physical units needs to be established. (x, y) represents the coordinates of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com