Automobile roof part drawing die

A technology for drawing dies and automobile top covers, applied in the field of automobile parts dies, can solve the problems of roughening at the feeding place, high scrap rate, dark cracks, etc., to reduce the normal wear speed, improve the hardness and finish, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

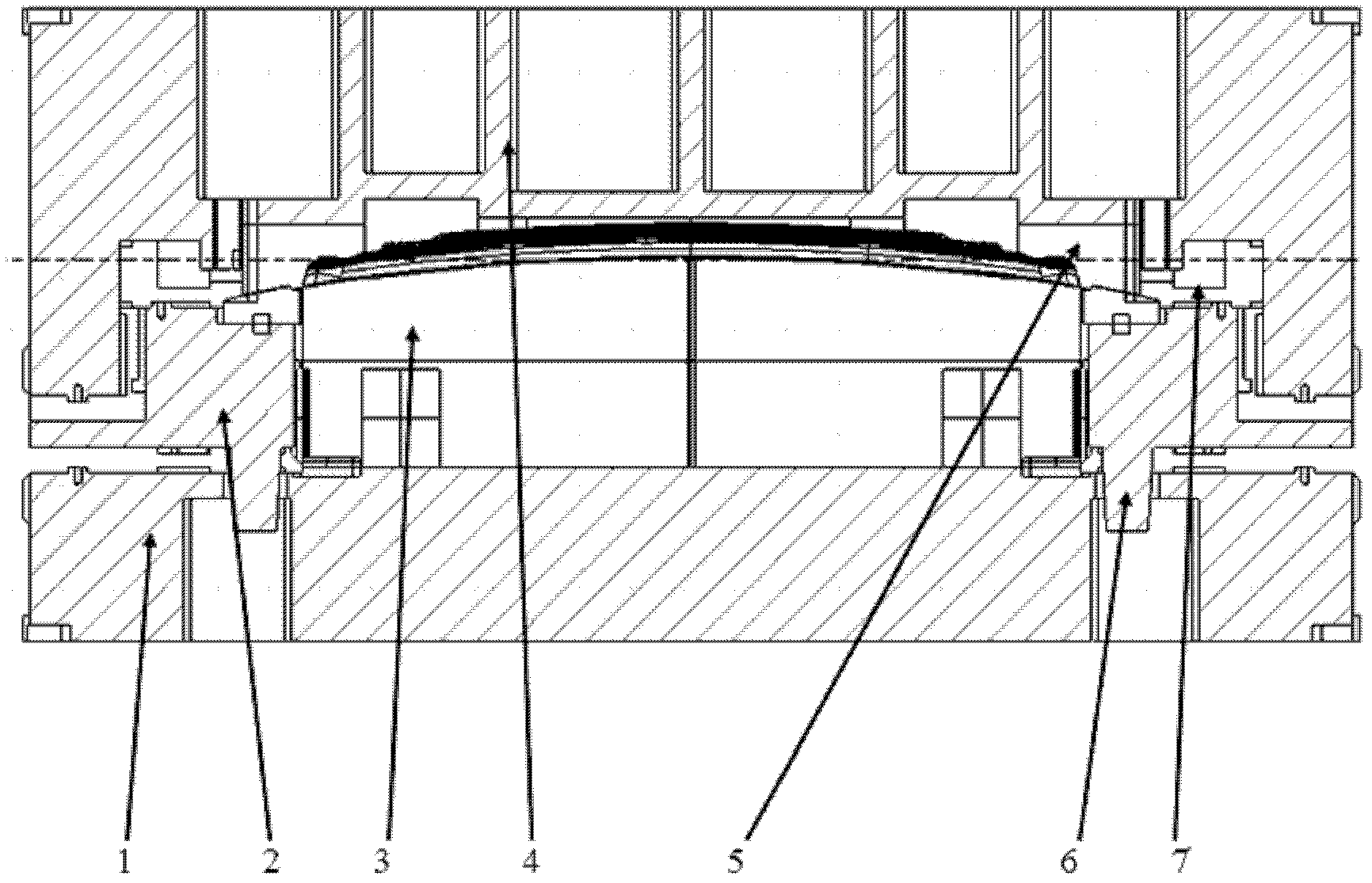

[0016] Such as figure 1 As shown, a drawing die for automobile roof parts includes three parts: a lower die assembly, a blanking plate, and an upper die assembly. The blanking plate is located between the lower die assembly and the upper die assembly.

[0017] The lower mold assembly includes a lower mold base 1 and a lower mold core 3, a guide plate, a guide pillar, and an ejector rod set on the lower mold base 1. The lower mold core 3 is set above the lower mold base 1, and the lower mold core 3 is provided Drawing punch with top cover;

[0018] The upper mold assembly includes an upper mold base 4, an upper mold core 5 and a guide plate guide sleeve set on the upper mold base 4. The upper mold core 5 is set below the upper mold base 4, and the upper mold core 5 is provided with a top Cover drawing die.

[0019] The pressing plate includes a pressing plate body 2, a pressing plate balance block 7 and a top rod cushion block 6. The top rod cushion block 6 is arranged between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com