A feed mechanism for an optoelectronic component testing machine

A technology for testing machines and feeding mechanisms, applied in the directions of conveyor objects, transportation and packaging, etc., can solve the problems of material jamming, narrow space for maintenance personnel activities, and restrictions, and achieve the problem of not easy material jamming and multi-design space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

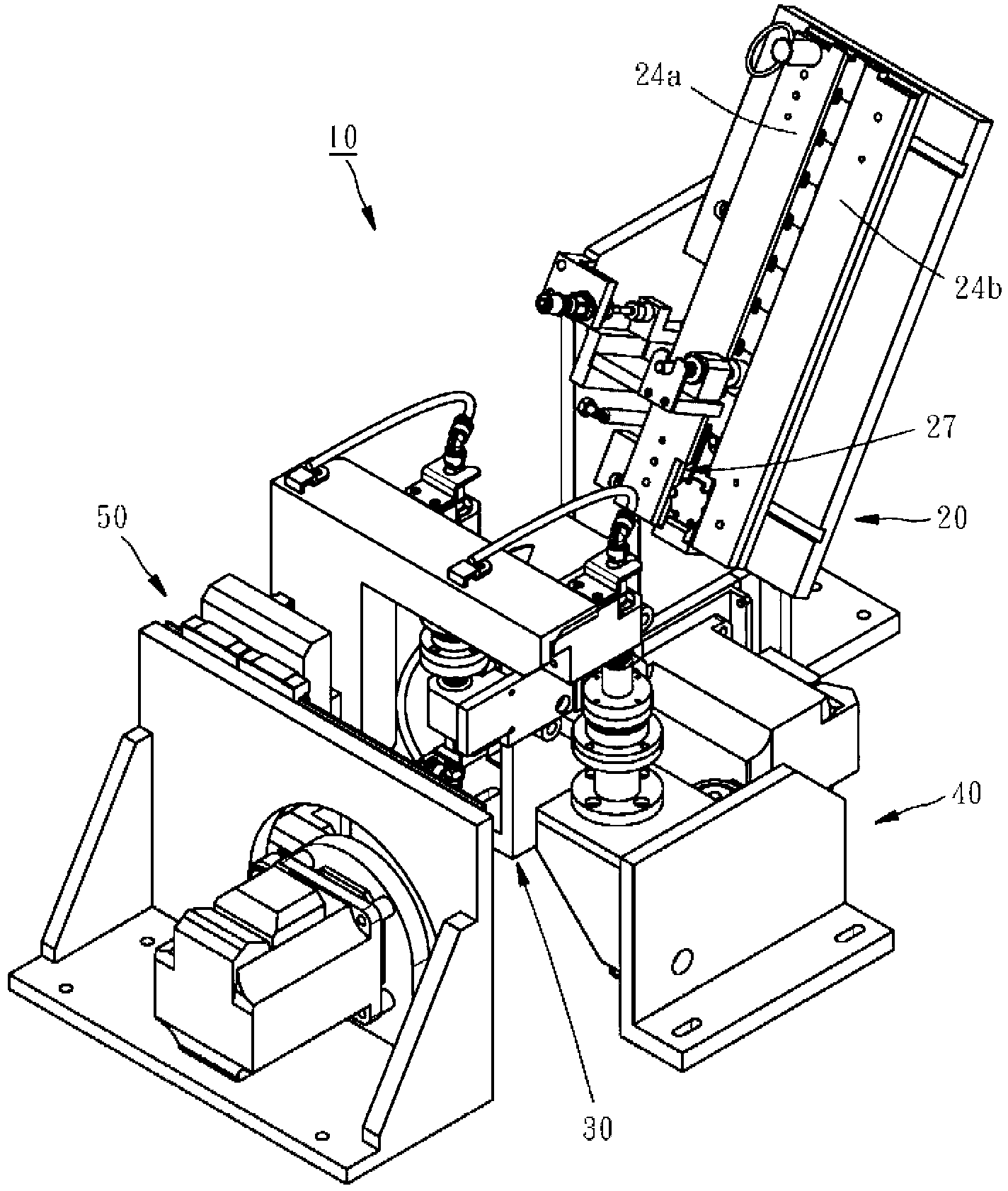

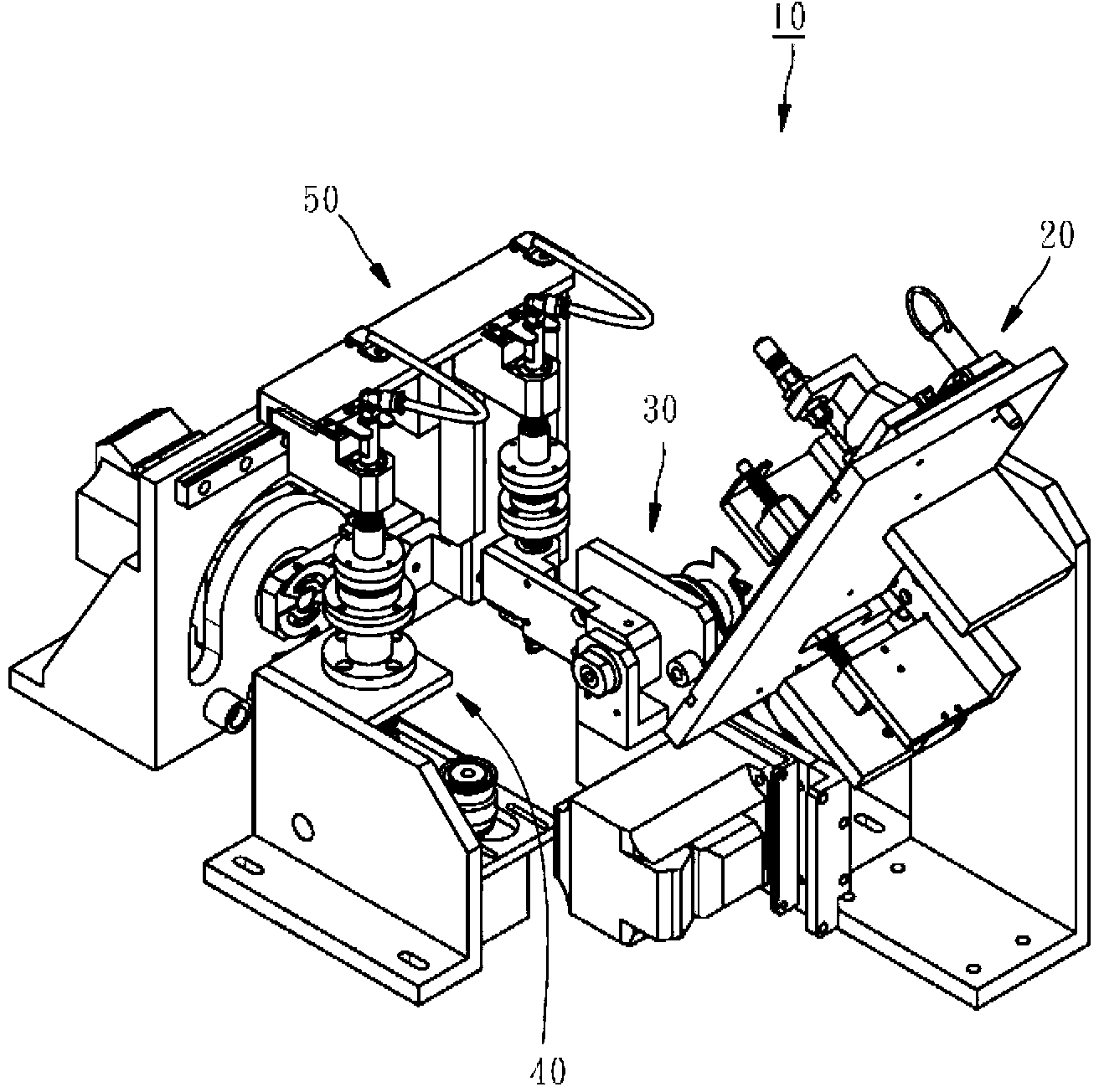

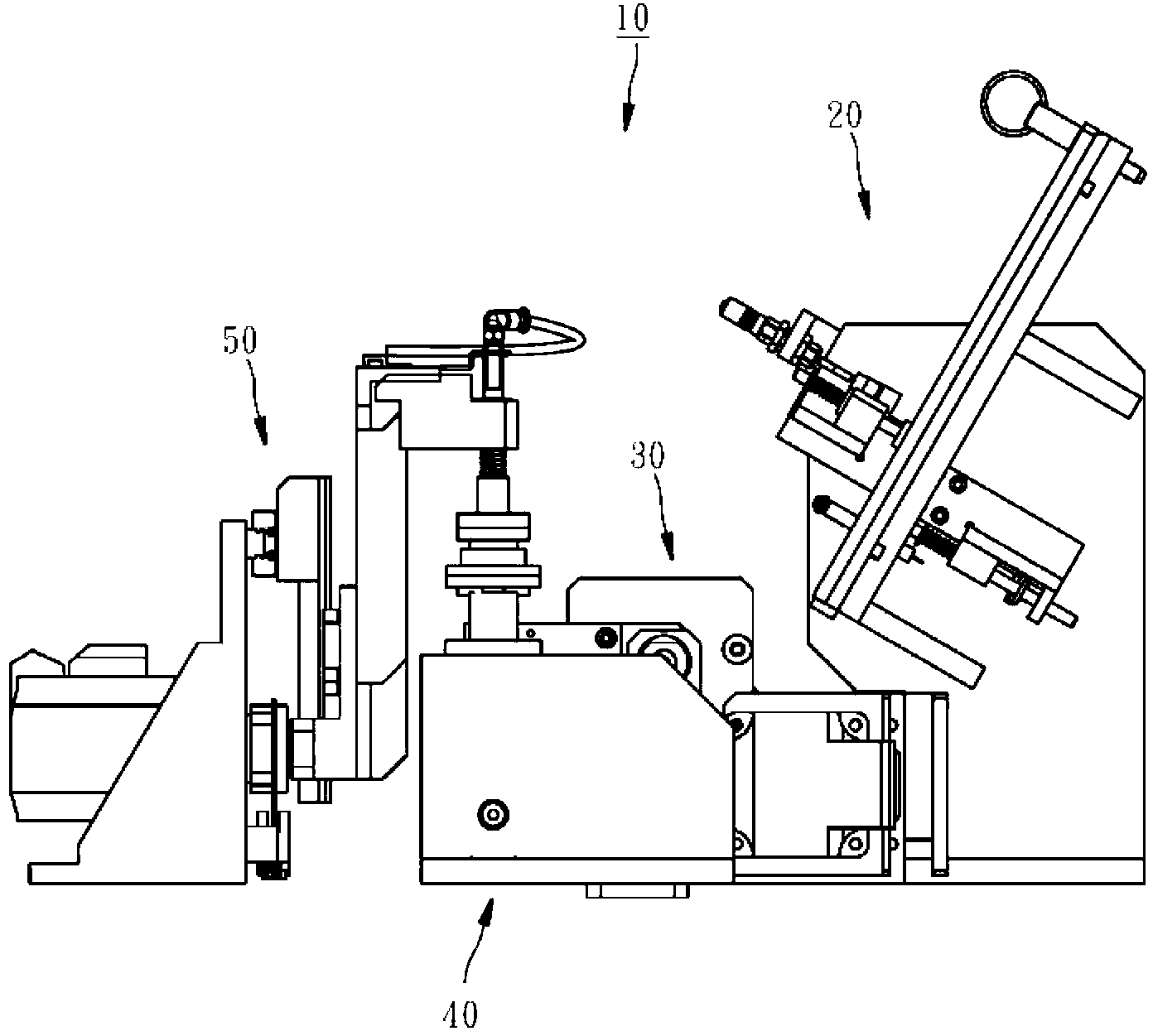

[0047] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0048] First, it must be stated that throughout the description of the present invention, and in the claims that follow, when it is mentioned that one member drives another member, it is meant that the member is driven directly or through other means such as a belt. component indirectly drives the other component. Likewise, when it is mentioned that a component is pivotally connected to or disposed on another component, it means that the component is directly or indirectly pivoted to or disposed on the other component through other components.

[0049] The main function of the feeding mechanism for the photoelectric component testing machine provided by the present invention is to deliver the material to be tested into a testing machine; wherein, the applicable material is such as (but not limited to) Optoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com