A kind of offset printing ink and preparation method thereof

A technology for offset printing ink and linseed oil, applied in the field of offset printing, can solve the problems of low ink roller sticking viscosity and offset printing ink sticking, etc., and achieves the effect of solving sticking ink rollers, improving printing suitability and improving printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

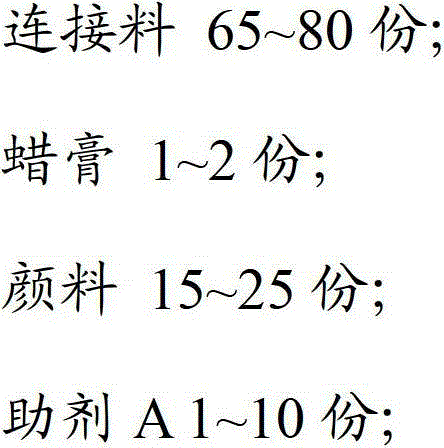

[0037] The magenta ink described in the present embodiment, its component is:

[0038] Connecting material 73.6 kg;

[0039] Wax paste 1.5 kg;

[0040] The pigments include 13 kilograms of Baohong 6BN and 5.5 kilograms of Baohong 8B, a total of 18.5 kilograms;

[0041] Auxiliary A includes 4.5 kg of viscosity modifier, 0.3 kg of anti-emulsification additive, 0.5 kg of flow aid, 0.5 kg of anti-wear agent, 0.1 kg of cobalt drying liquid, and 0.5 kg of manganese drying liquid, a total of 6.4 kg.

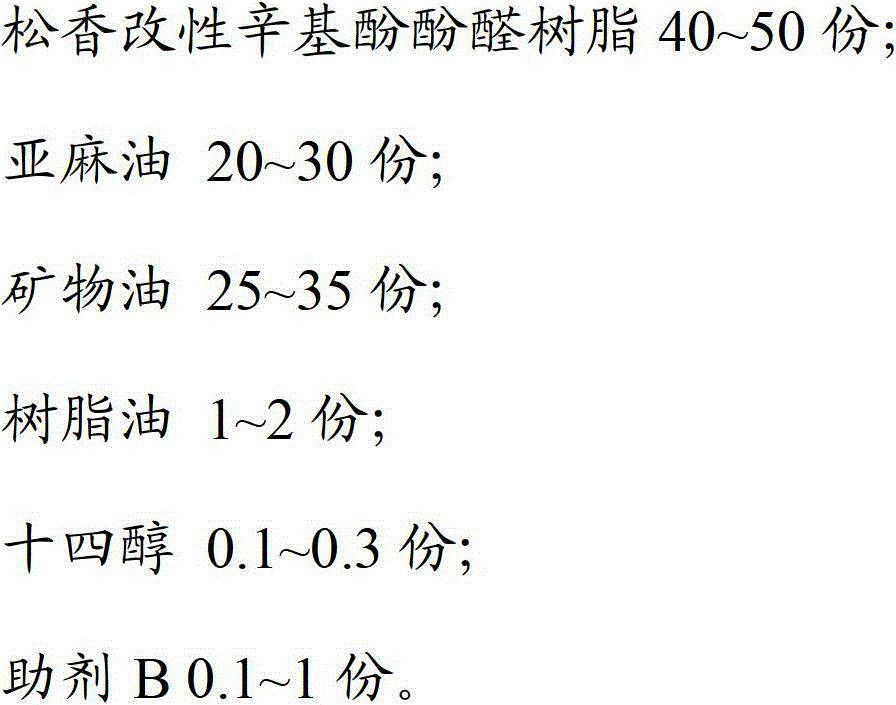

[0042] Described connecting material, its component and each component weight portion are:

[0043]

[0044] Auxiliary B includes 0.6 parts of liquid gel, 0.1 parts of BHT, 0.7 parts in total.

[0045] Described wax paste, its component and each component weight portion are:

[0046]6.6 parts of linseed oil:

[0047] 67 parts of mineral oil;

[0048] Beeswax 26.4 parts.

[0049] The concrete preparation steps of described offset printing ink are:

[0050] S1, weigh rosin modi...

Embodiment 2

[0055] The middle yellow ink described in the present embodiment, its component is:

[0056] Connecting material 73.815 kg;

[0057] Wax paste 1.5 kg;

[0058] The pigment is 178-1 yellow, 18 kg;

[0059] Auxiliary A includes 5 kg of viscosity modifier, 0.3 kg of anti-emulsification additive, 0.5 kg of flow aid, 0.5 kg of antiwear agent, 0.06 kg of cobalt drying liquid, and 0.325 kg of manganese drying liquid, totaling 6.685 kg.

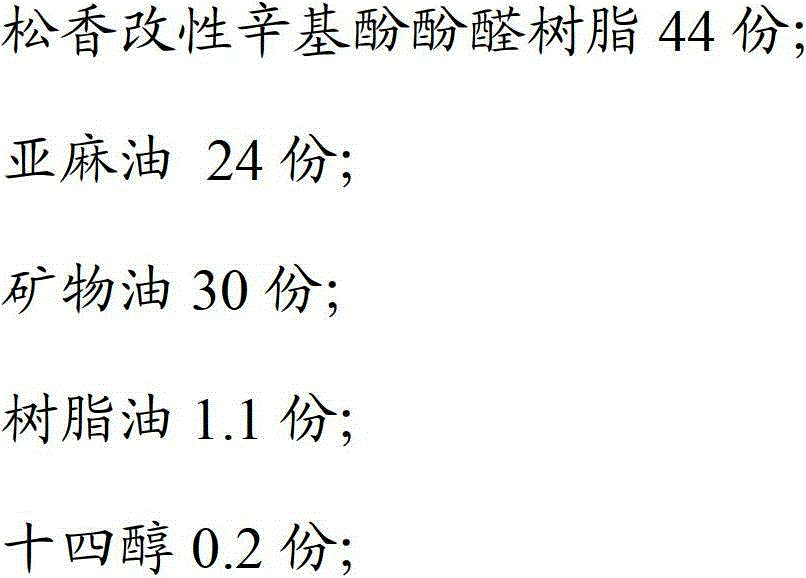

[0060] Described connecting material, its component and each component weight portion are:

[0061]

[0062] Described wax paste, its component and each component weight portion are:

[0063] 5 parts flaxseed oil:

[0064] 55 parts of mineral oil:

[0065] 40 parts of beeswax.

[0066] The concrete preparation steps of described offset printing ink are:

[0067] S1, weigh rosin modified octylphenol phenolic resin, linseed oil, mineral oil, resin oil, myristyl alcohol and auxiliary agent B according to the selected parts by weight, after res...

Embodiment 3

[0072] Sky blue ink described in the present embodiment, its component is:

[0073] Connecting material 79.25 kg;

[0074] Wax paste 1.5 kg;

[0075] The pigment is 94817 blue 17.5 kg;

[0076] Auxiliary A includes 0.3 kg of anti-emulsification additive, 0.5 kg of flow aid, 0.6 kg of anti-wear agent, 0.05 kg of cobalt drying liquid, and 0.3 kg of manganese drying liquid, totaling 1.75 kg.

[0077] Described connecting material, its component and each component weight portion are:

[0078]

[0079] Described wax paste, its component and each component weight portion are:

[0080] 5 parts flaxseed oil:

[0081] 75 parts of mineral oil:

[0082] 20 parts beeswax.

[0083] The concrete preparation steps of described offset printing ink are:

[0084] S1, weigh rosin modified octylphenol phenolic resin, linseed oil, mineral oil, resin oil, myristyl alcohol and auxiliary agent B according to the selected parts by weight, after reserving the mineral oil of 5wt% parts by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com