Die

A mold and integral technology, applied in the direction of manufacturing tools, heat treatment equipment, quenching devices, etc., can solve the problems of long replacement time, high labor intensity, unstable replacement quality, etc., achieve low cost, simple and convenient operation, and avoid loss of support devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

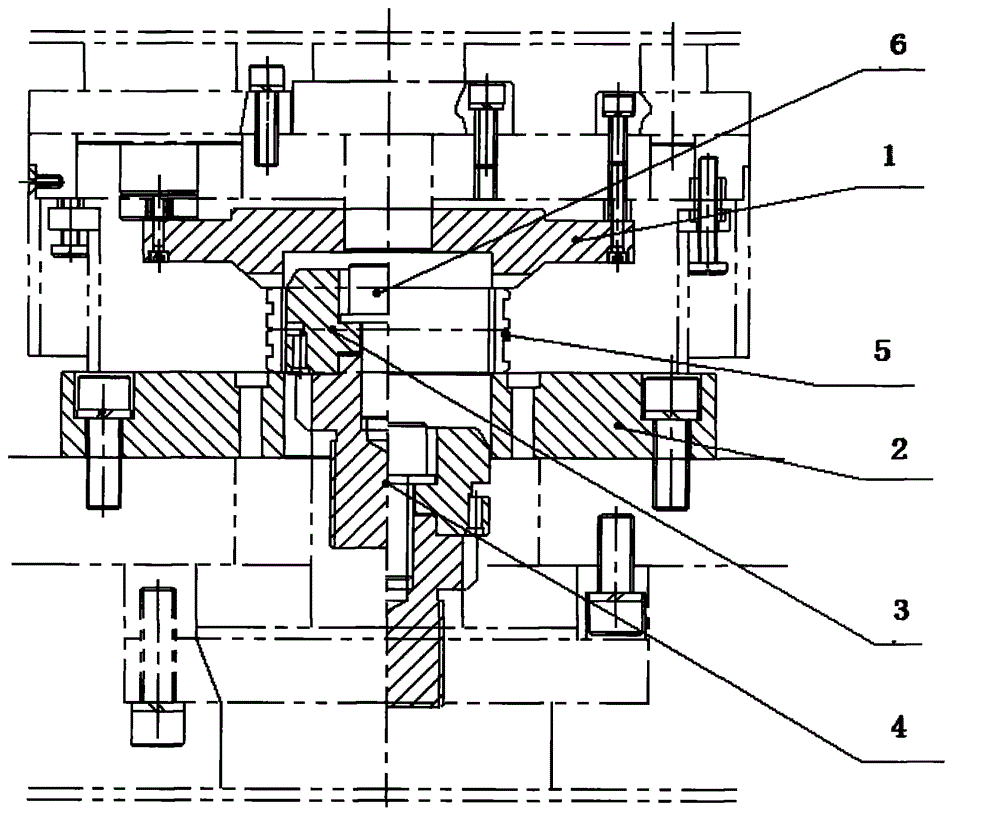

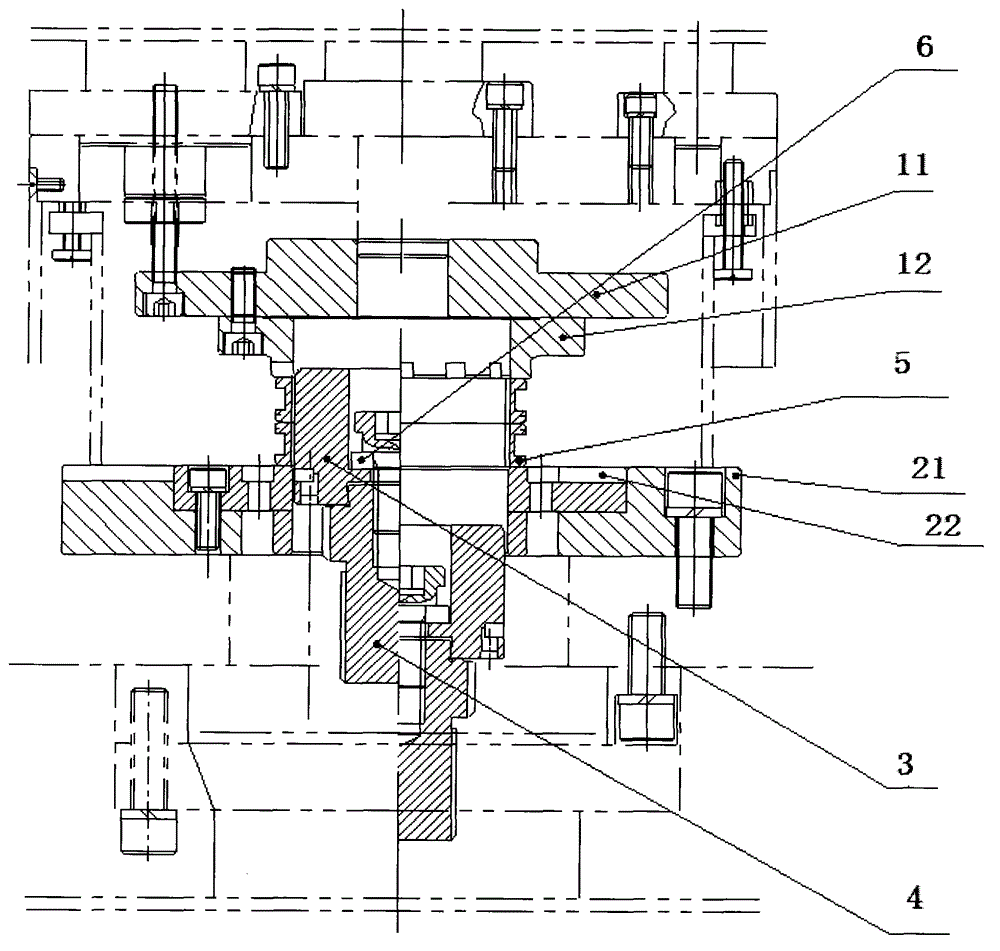

[0023] Combine below figure 2 , the present invention is further described:

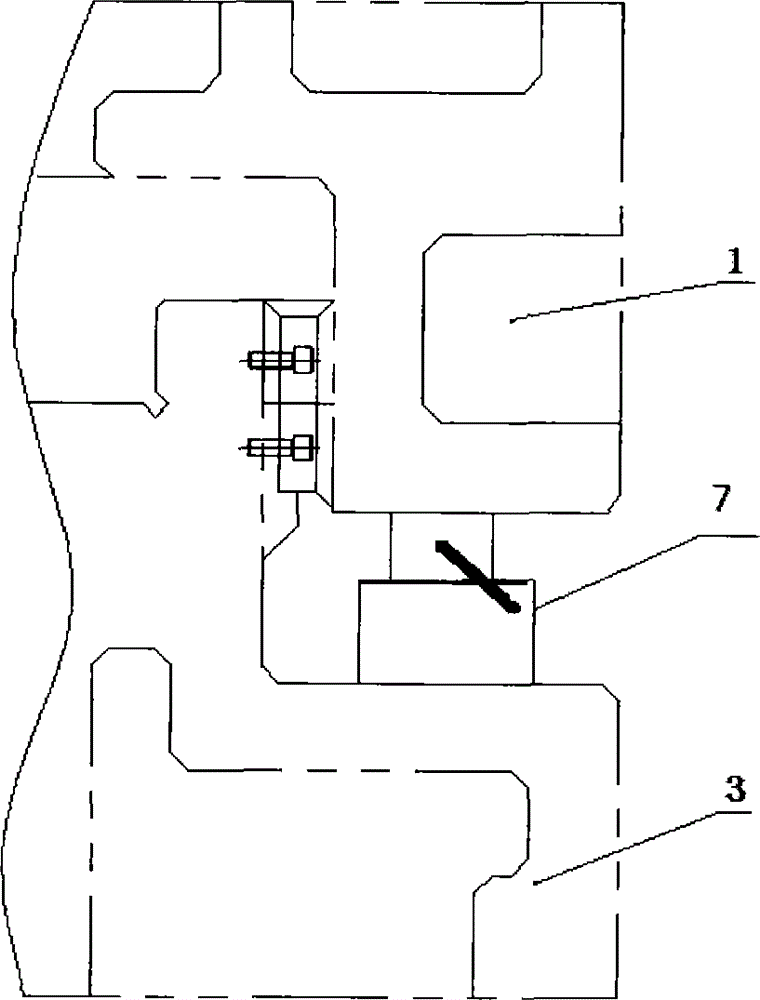

[0024] A mold comprising a mandrel 3, an integral upper die 1 and an integral lower die 2, the integral upper die 1 is composed of a basic upper die 11 and a quick-change upper die 12, the basic upper die 11 is fixedly connected to the main oil cylinder of a machine tool, The quick-change upper die 12 presses down on the upper surface of the workpiece 5. The quick-change upper die 12 is a detachable and replaceable structure. The basic upper die 11 and the quick-change upper die 12 are fixed by fixing bolts; The lower die 21 and the quick change die 22 are combined. The basic lower die 21 is fixedly connected with the machine tool. Lower die 21 and fast change die 22 are also fixed by fixing bolts.

[0025] The mandrel 3 is positioned on the connecting shaft 4, the mandrel 3 and the connecting shaft 4 are fixed by the connecting bolt 6, and the connecting shaft 6 is connected to the machine tool. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com