Connection structure of prestressed reinforced concrete hollow square pile

A reinforced concrete and connection structure technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of being easily affected by weather and human factors, the reliability of joint quality is not high, and the welding quality is not stable enough, etc., to achieve The effect of saving the natural cooling time, shortening the pile connection time, and saving the pile connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

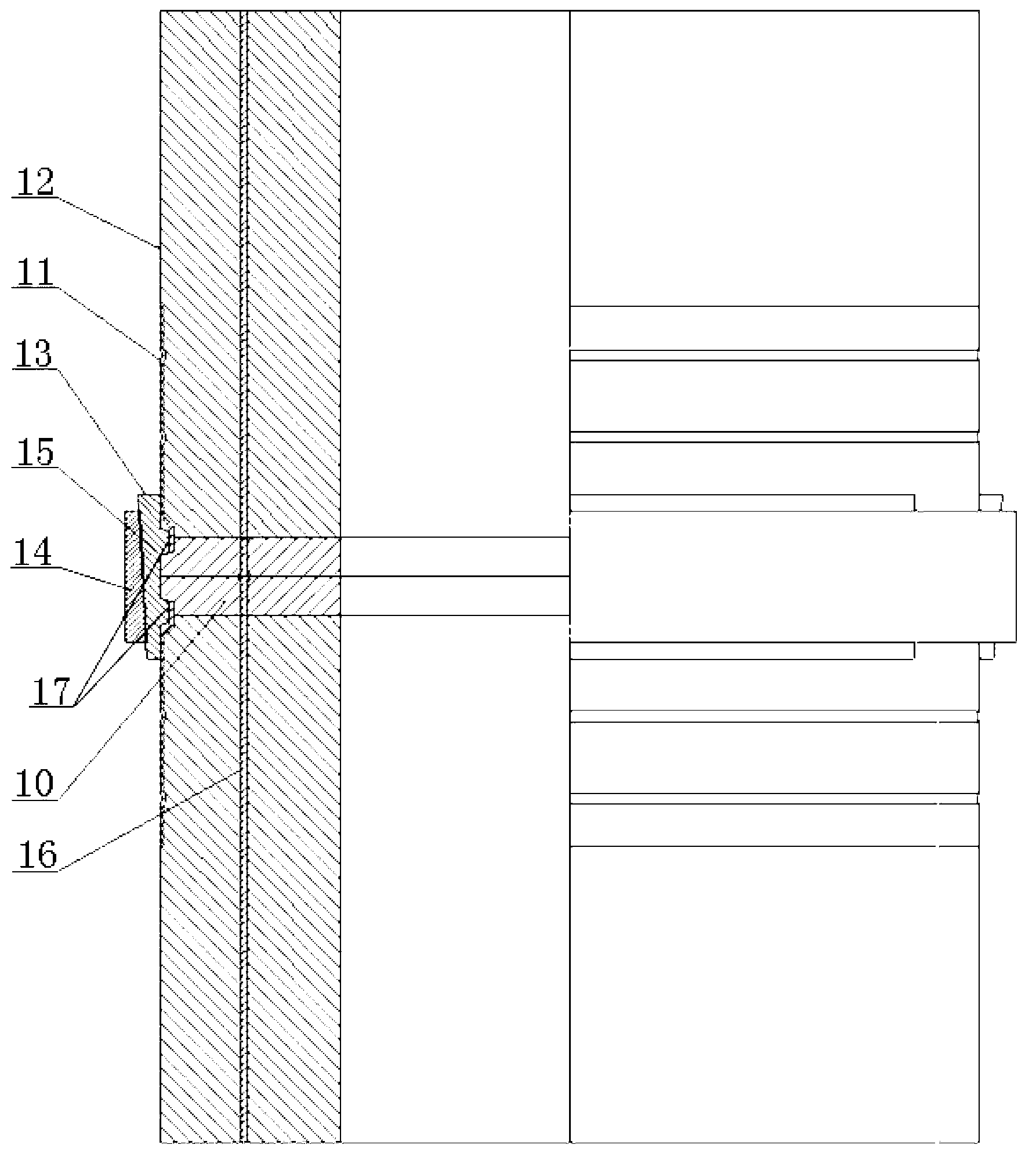

[0031] The first embodiment of the connecting structure of the prestressed reinforced concrete hollow square pile provided by the present invention, such as figure 1 , figure 2 As shown, it includes an end plate, an internal pressure buckle and an external fastener. The end plate is arranged at the connecting end of the pile body 12, and it is composed of an end plate 10 and a skirt plate 11. The end plate 10 is provided with There are bolt holes (not marked in the figure) and tension holes (not marked in the figure), the radial size of which is the same as that of the pile body 12 , and the skirt plate 11 is sleeved on the end plate 10 . The internal pressure fastener is sleeved on the outside of the end plate 10, and the external fastener is sleeved on the outside of the internal pressure fastener and forms an axial lock with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com