Partition board and inner insertion tube structure of air suction silencer for compressor

A technology of inner tube and muffler, which is applied in the direction of machines/engines, mechanical equipment, liquid displacement machinery, etc. It can solve the problem of reducing the overall performance of compressors, it is difficult to meet low noise and high efficiency at the same time, and increase suction The muffler suction resistance and other issues, to achieve the effect of taking into account noise reduction, high efficiency performance requirements, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

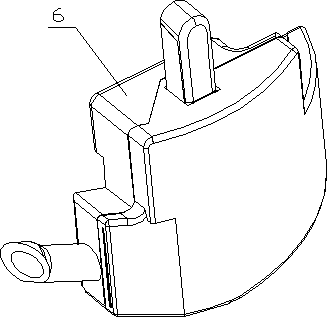

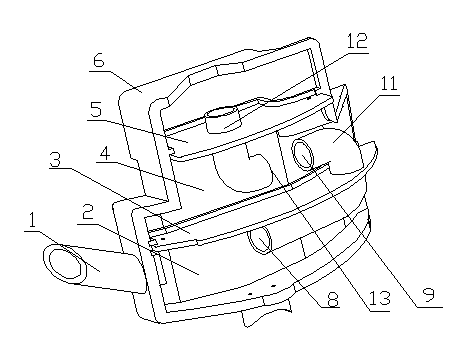

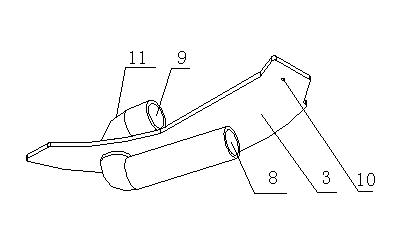

[0014] Such as figure 2 As shown, the separator inner tube structure of the compressor suction muffler of the present invention includes a first separator 3, a first inner tube 11, a second separator 5 and a second inner tube 12, and the first inner tube Tube 11 is U-shaped (see also Figure 4 ), which is located on the first partition 3. The second inner insertion tube 12 is bent, and it is arranged on the second partition 5 . The lengths of the two arms of the first intubation tube 11 are adjusted according to the frequency bands that the muffler needs to eliminate noise, so that the noise elimination of the secondary frequency bands can be taken into account when eliminating the noise of the main frequency bands. The first partition 3, the second partition 5 and the muffler housing 6 are connected by direct buckling (please also refer to figure 1 ), the second partition 5 divides the interior of the muffler into two chambers, and the first partition 3 divides the muffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com