Measuring method for output frequency of frequency converter of variable frequency fan under different working conditions

A frequency conversion fan and output frequency technology, applied in the direction of frequency measurement devices, etc., can solve the problems of large differences in pipelines, the extraction of toxic and harmful gases cannot meet the requirements, and the power saving is not obvious, and achieve the effect of great energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

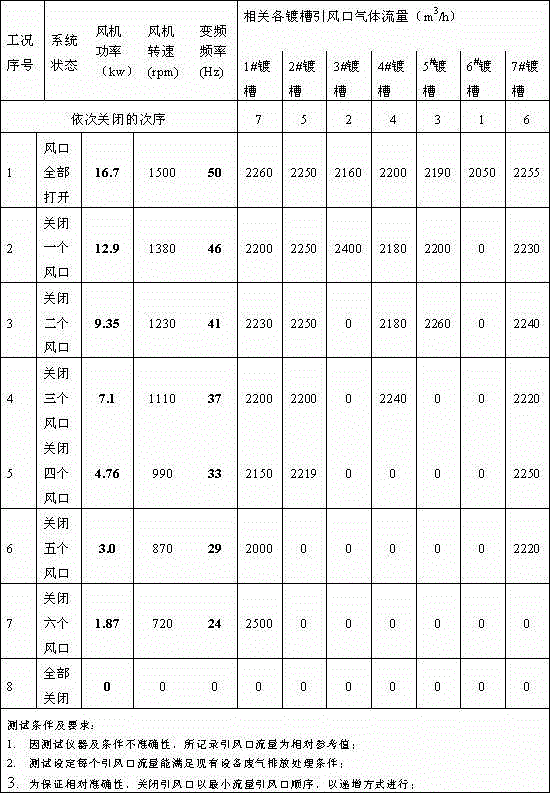

[0007] The method for measuring the output frequency of the frequency conversion fan inverter under different working conditions of the present invention: in the running state of the frequency conversion fan, each air inlet of the frequency conversion fan is fully opened, the frequency conversion fan is running at full frequency, and the gas flow rate of each air inlet is detected and recorded respectively by using a detection instrument and the power, speed, and output frequency of the variable frequency fan, and then close the air inlets of the variable frequency fans in order from small to large, until all the air inlets are closed, and at the same time adjust the output frequency of the inverter to the gas flow rate of the opened air inlets. When the tuyere is fully open, the gas flow rate of the air inlet is equivalent, and the output frequency of the frequency converter, the power and speed of the frequency conversion fan are recorded in sequence, so as to obtain the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com