Innovative new technology of preparing gallium using ion exchange method

An ion exchange method and ion exchange technology, applied in the field of metal hydrometallurgy, can solve problems such as incomplete desorption, low system concentration, and difficult adsorption, and achieve the effects of increasing production capacity, scientific and reasonable process, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

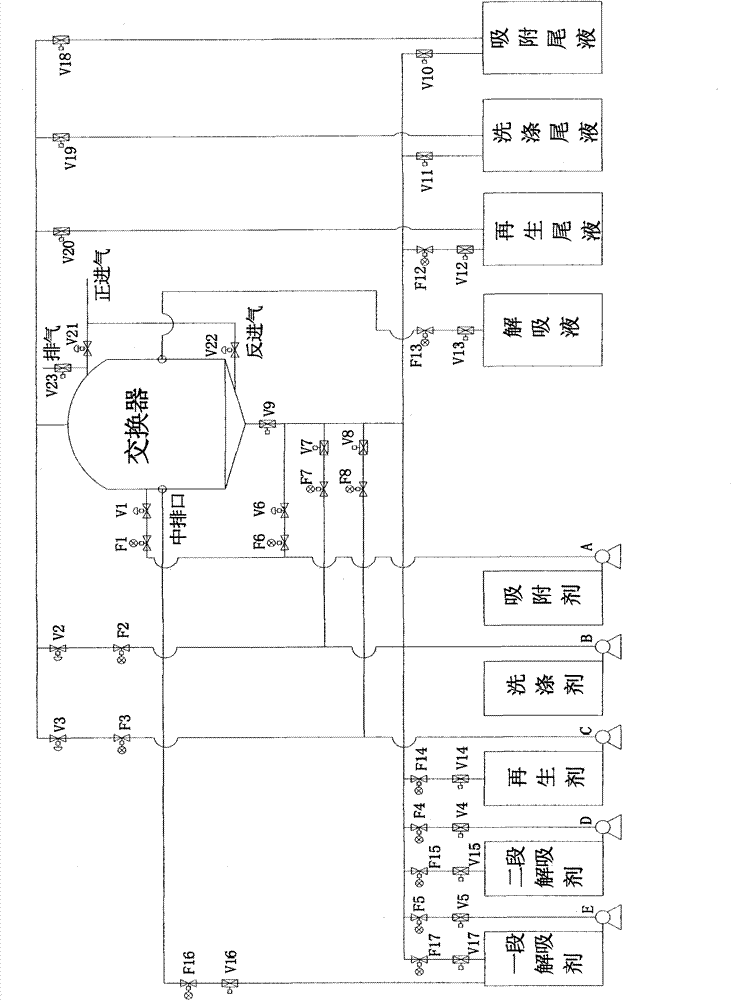

Image

Examples

Embodiment Construction

[0013] The new process for producing metal gallium by the ion exchange method of the present invention utilizes the fixed bed ion exchange separation technology, adds compressed air wind stirring and extruding processes, and adopts the method of two-stage reverse desorption. The specific control steps are as follows:

[0014] (1) Operation of the adsorption unit: open the forward liquid inlet valve 1 of the seed separation mother liquid, the recovery valve 10 of the adsorption tail liquid and the conveying equipment A, the seed separation mother liquid enters from the middle of the reactor, and the flow rate in the resin layer is 5-6m / h, When the pressure in the reactor gradually rises to 150KPa, the forward liquid inlet valve 1 of the mother liquor, the recovery valve 10 of the adsorption tail liquid and the conveying equipment A are automatically closed, and the reverse inlet valve 22 and the reverse outlet valve 18 of the adsorption tail liquid are opened. Enter 0.25~0.30MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com