Gas back-extraction type water drainage device

A technology of gas and gas pipes, applied in the field of gas back-pumping water discharge devices, which can solve problems such as inability to discharge, accumulation, and reduced area of gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

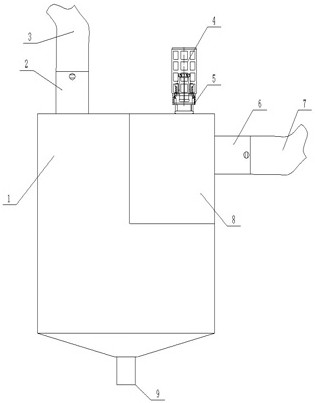

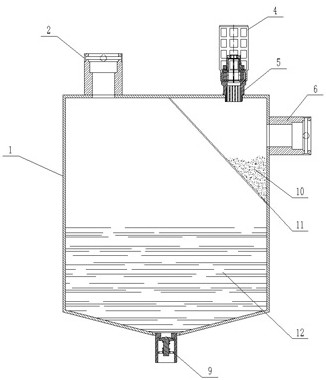

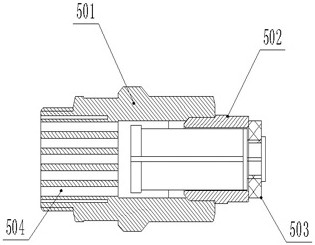

[0014] With reference to the figures covered in the accompanying drawings and specific practical instructions are as follows:

[0015] As shown in the figure, a gas reverse pumping type water release device is composed of three parts: a storage box 1, a safety valve group 5, and an automatic discharge valve group 9. A drilled gas pipe connector 6 is installed on one side of the storage box 1 , the drilled gas pipe connector 6 can be connected with one or more drilled gas pipes 7, the upper side of the storage box 1 is provided with a roadway gas pipe connector 2, and through the roadway gas pipe connector 2 and the roadway gas pipe 3 To connect, a slag-water separation mechanism 11 is installed in the storage box 1, and the cinder 10 and water 12 are separated through the slag-water separation mechanism 11. When the cinder 10 accumulates for a certain period of time, the cinder 10 can be cleaned out through the side opening plate 8. Storage box 1.

[0016] According to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com