Thermal cycler

A heat cycle and radiator technology, applied in laboratory appliances, chemical instruments and methods, heating or cooling equipment, etc., can solve the problems of reduced efficiency and complex efficiency, and achieve the effect of high heat transfer ratio efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

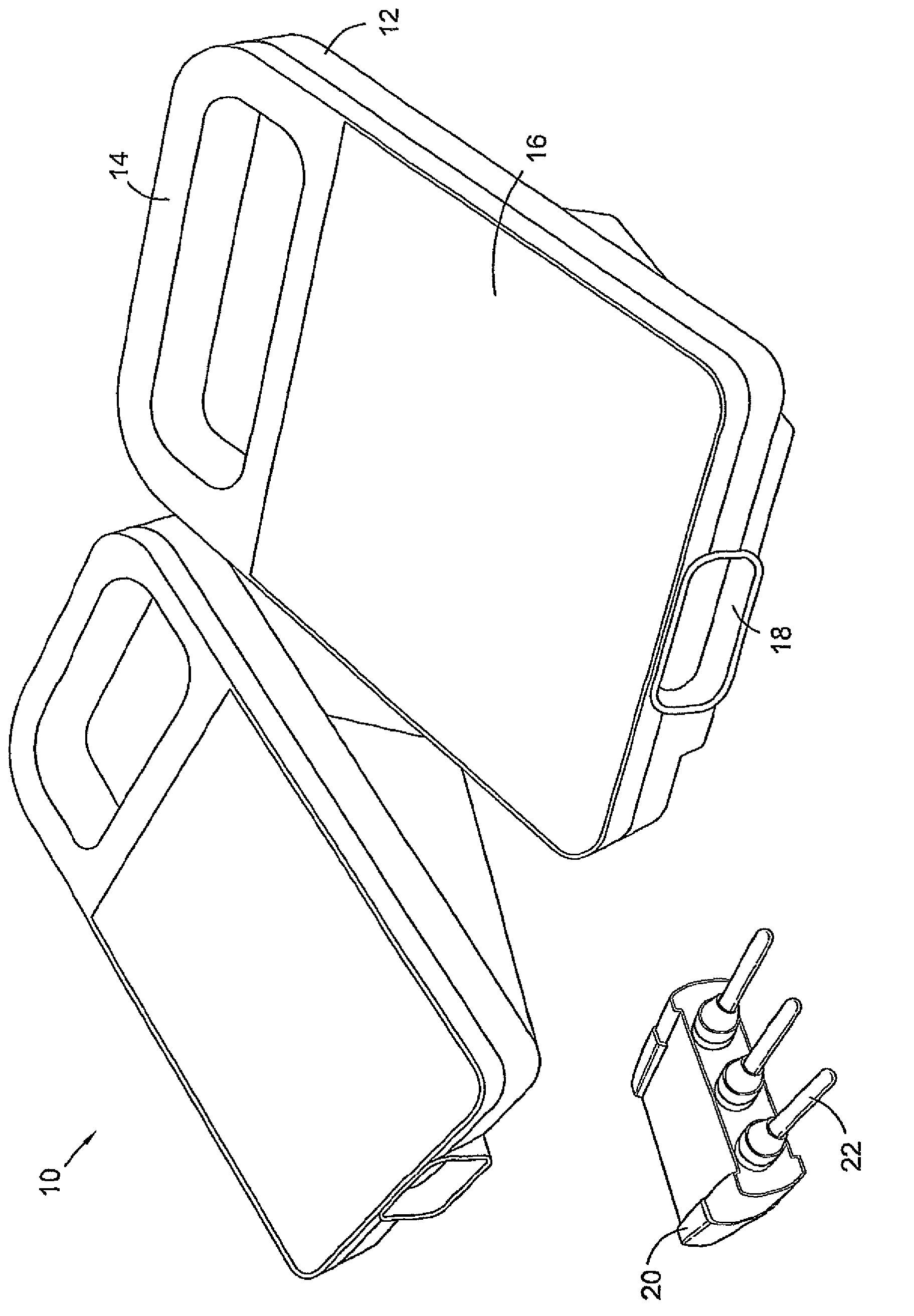

[0035] First refer to figure 1 , which shows an external view of a thermal cycler according to the present invention. The circulator 10 includes a housing 12 forming a handle 14 . The upper surface of housing 12 is provided with a touch screen interface 16 that allows a user to operate the circulator. The front of the housing is provided with an opening 18 into which a sample holder 20 can be inserted, said sample holder 20 comprising (in this embodiment) three sample tubes 22 made of thin-walled plastic.

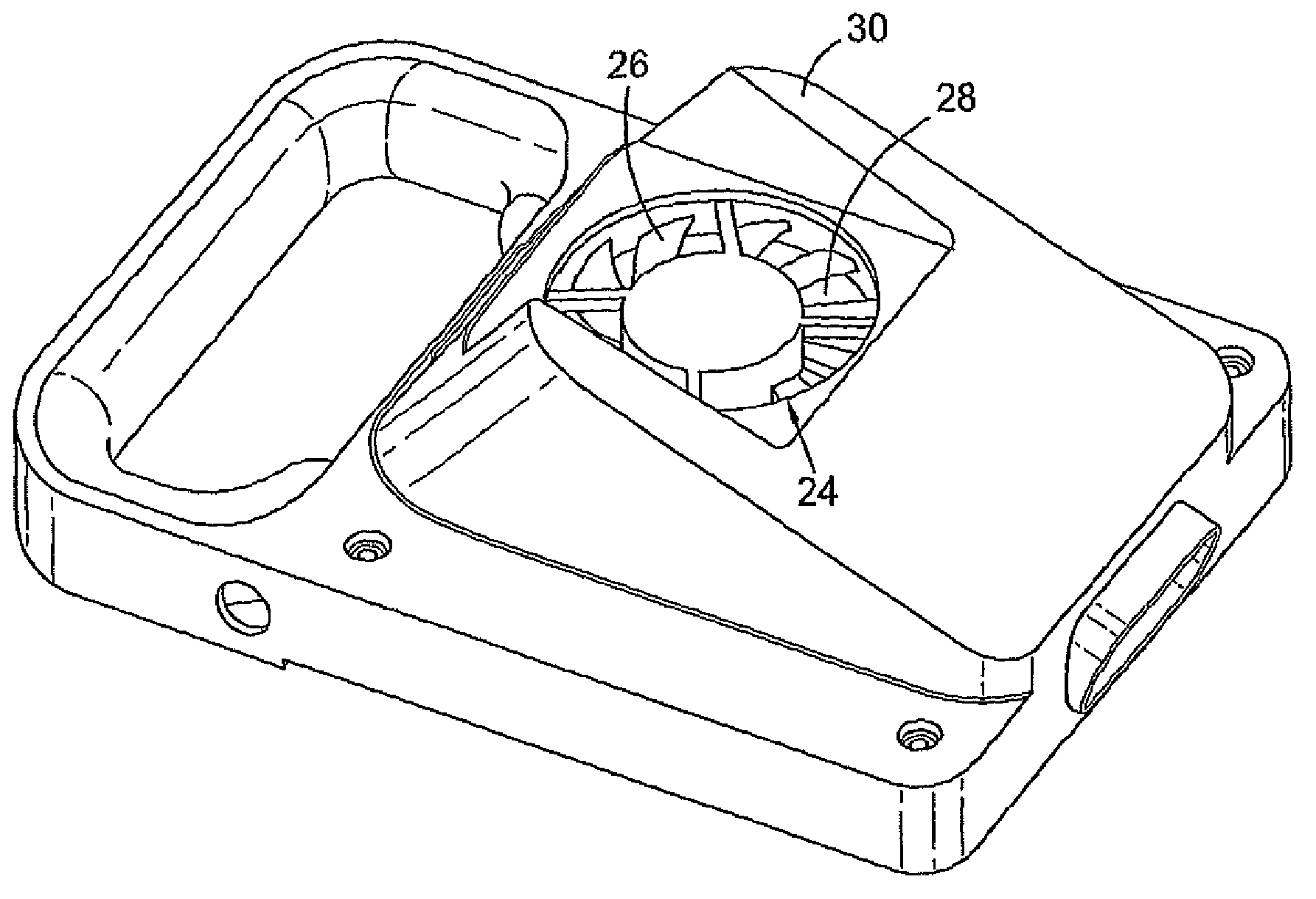

[0036] figure 2 The underside of the circulator 10 is shown in . The housing includes an opening 24 within which a cooling fan 26 is mounted, adjacent to a heat sink 28 . The housing is formed with supports 30 which lift the fan 26 off the bench top allowing air to circulate.

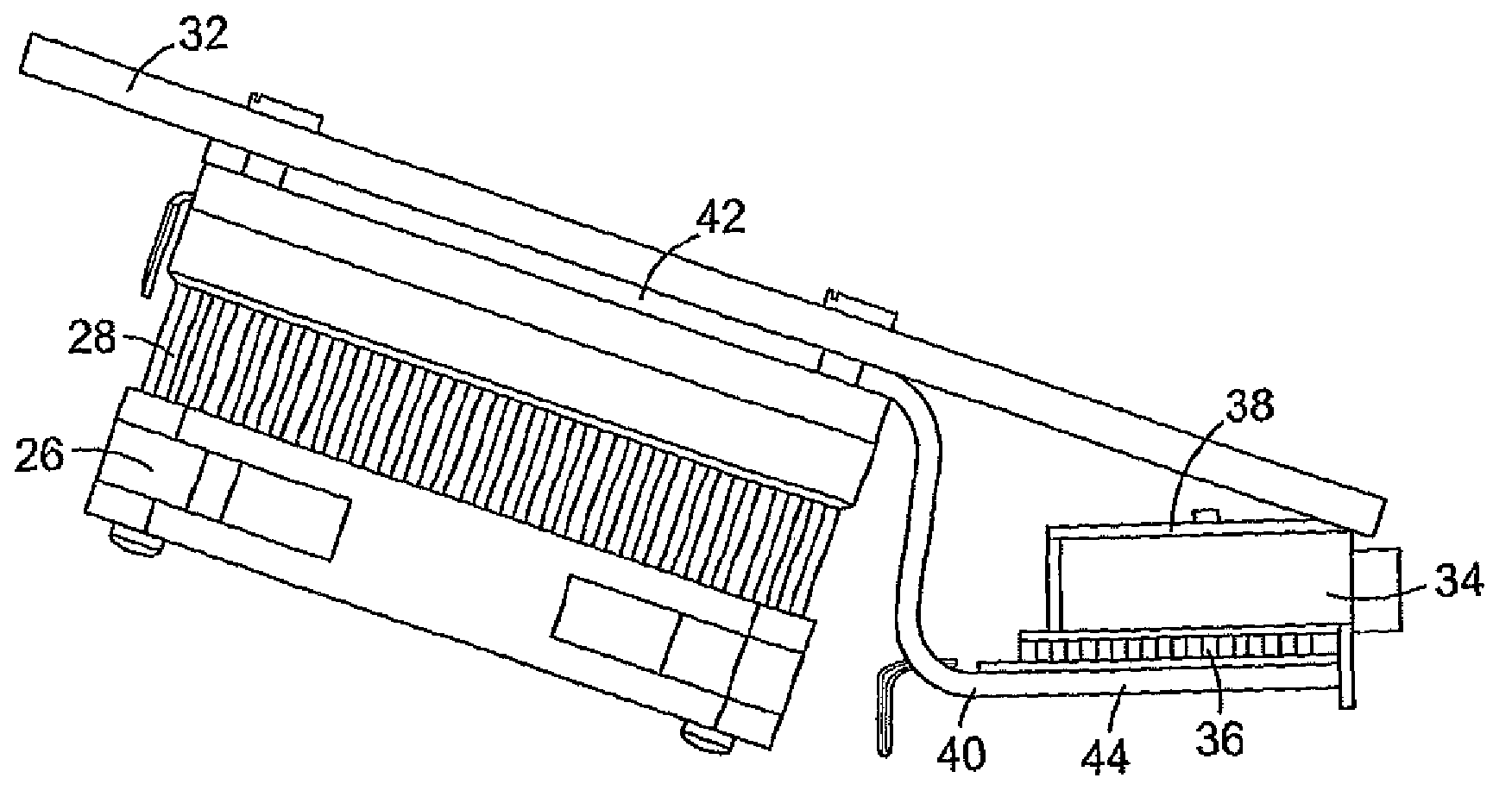

[0037] image 3 The internal architecture of the circulator 10 is shown in . Housing 12 is not shown in this figure. A PCB substrate 32 is provided on which the various electronic components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com