Air spring device

An air spring and elastomer technology, applied in springs, low internal friction springs, springs/shock absorbers, etc., can solve the problems of reduced durability of elastic components and reduced durability of air spring devices, and achieves vertical spring constant and The effect of reducing the horizontal spring constant, ensuring ride comfort, and excellent ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

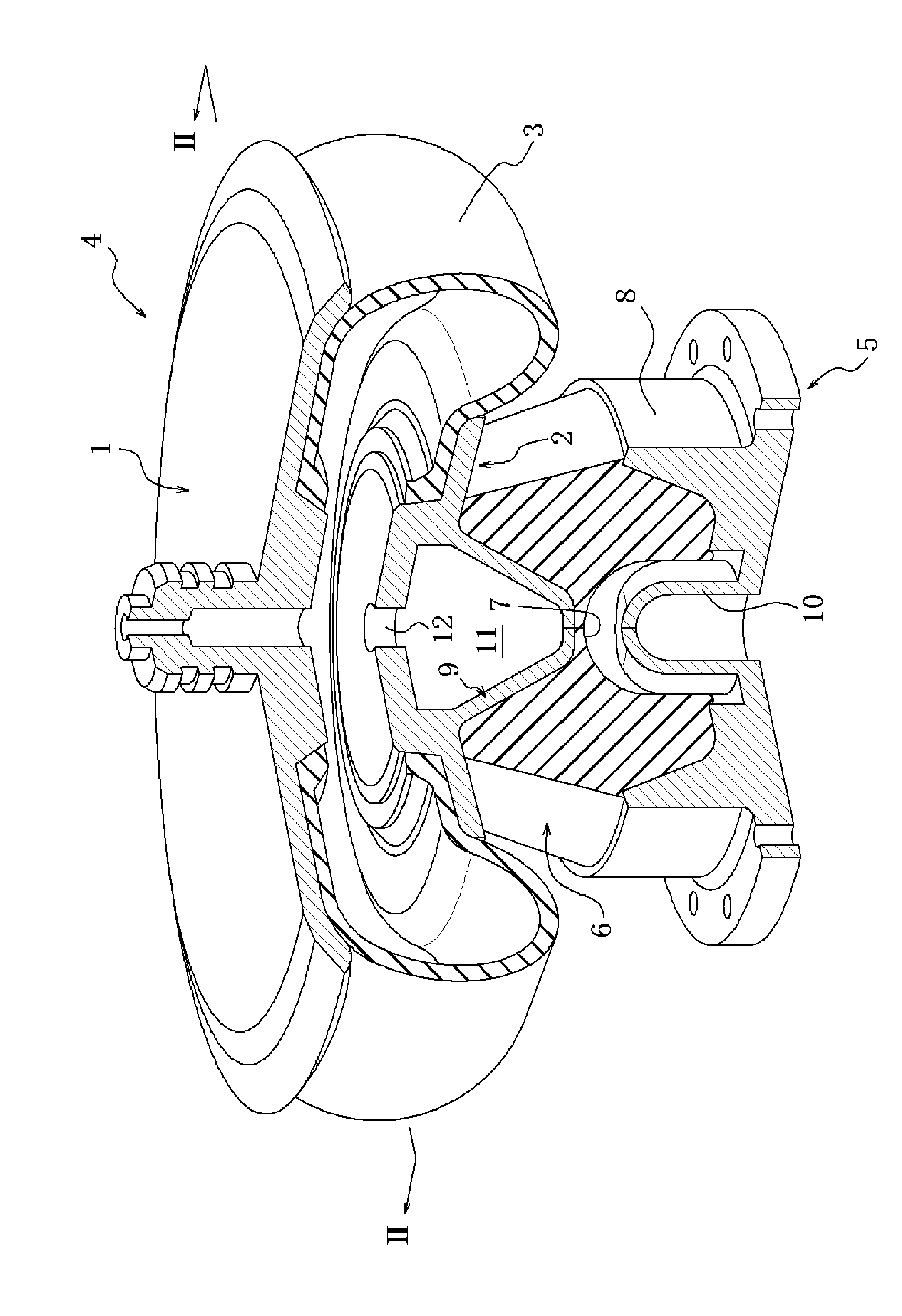

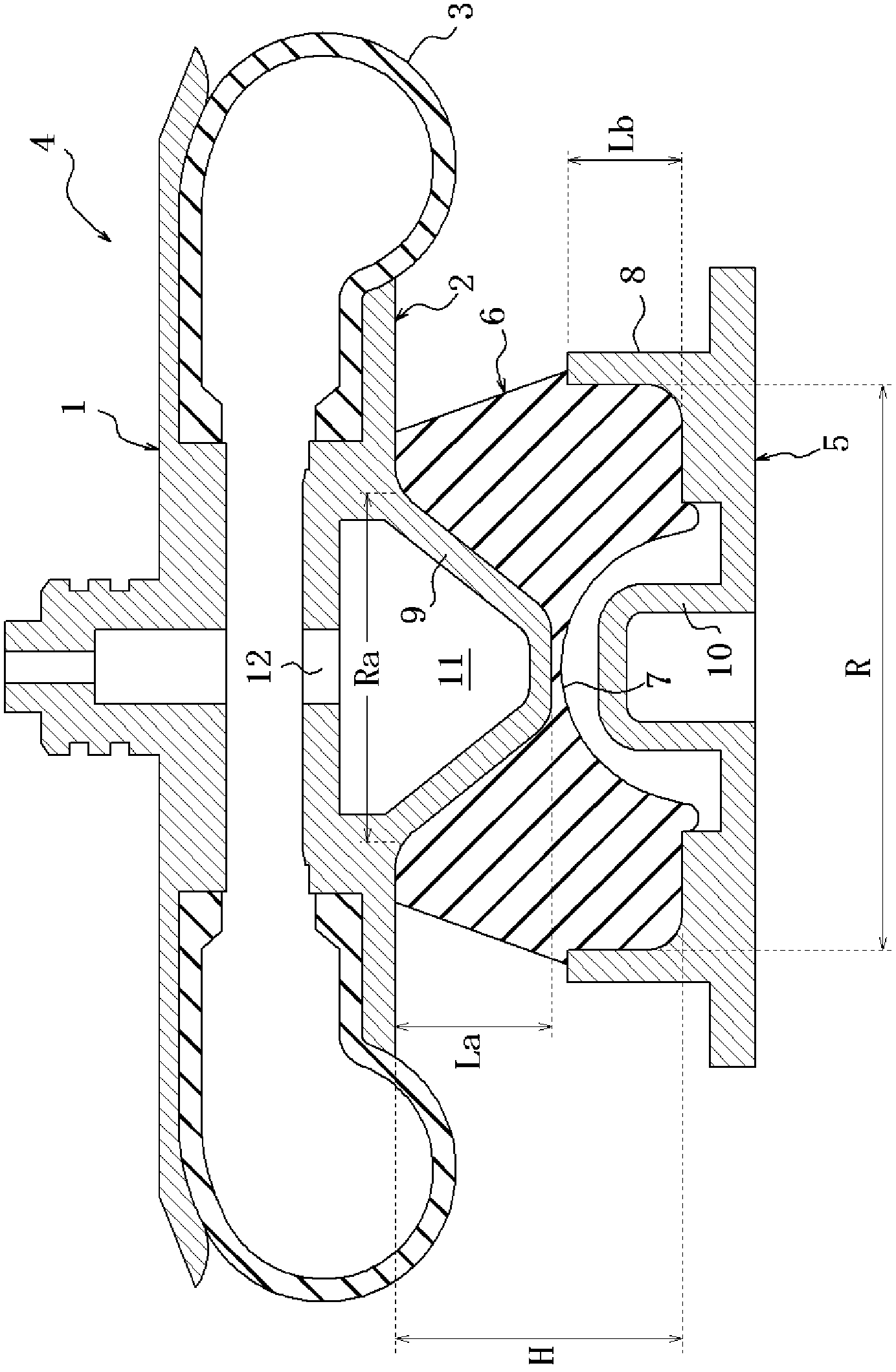

[0021] Embodiments of the present invention will be described below with reference to the drawings. figure 1 The air spring device shown in includes: an air spring 4, which has a gas-filled interior defined by an upper panel 1, a lower panel 2 and a cylindrical flexible membrane body 3, and both the upper panel 1 and the lower panel 2 may have discs shape, the cylindrical flexible membrane body 3 has, for example, an embedded reinforcement layer (not shown) inside it and airtightly connects each panel; a support plate 5, which is arranged at a distance from the lower panel 2 of the air spring 4 in this embodiment a position at a given distance; and an elastic body 6 connecting the support plate 5 and the lower panel 2 . It should be noted that although not shown in the figure, the upper panel and the support plate can be connected by elastic bodies to have the same figure 1 The air spring device is shown in an upside-down position.

[0022] The upper panel 1 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com