Optical fiber, optical transmission path, and optical fiber manufacturing method

A manufacturing method and optical transmission technology, applied in clad optical fiber, multi-layer core/clad optical fiber, graded index core/clad optical fiber, etc., can solve problems such as ambiguity, and achieve the goal of reducing mode dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] 〔Structure of optical fiber〕

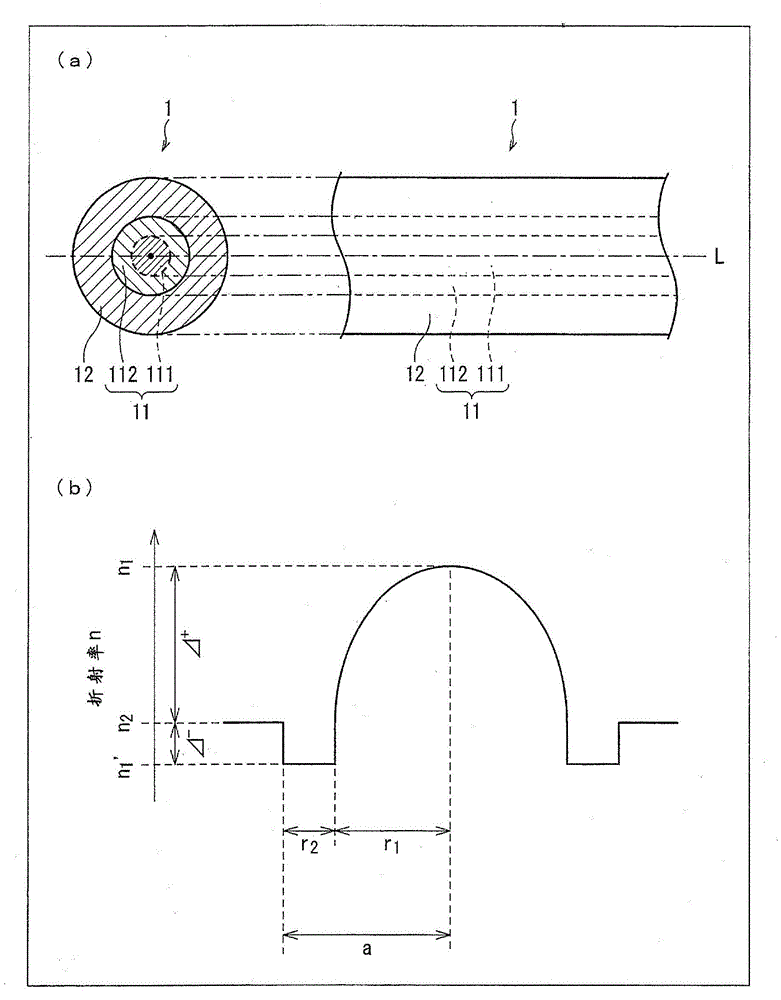

[0036] refer to figure 1 The structure of the optical fiber 1 of this embodiment will be described. figure 1 (a) is a side view and a cross-sectional view of the optical fiber 1, figure 1 (b) is a graph showing the refractive index distribution of the optical fiber 1 . also, figure 1 (b) The refractive index profile shown is at figure 1 In the optical fiber 1 shown in (a), with the central axis L (refer to figure 1 (a)) Refractive index profile on orthogonal straight lines.

[0037] Such as figure 1 As shown in (a), the optical fiber 1 is a cylindrical structure mainly composed of silica glass. a, cladding 12 with a cross-section shaped like the outer circumference radius b). According to the difference in refractive index distribution, the core 11 is further divided into an inner core 111 having a disk (radius r1)-shaped cross section, and an annular ring (inner radius r1, outer radius r1+r2) surrounding the inner core 111. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com